Current sensor for automobile collision test

A current sensor and collision test technology, which is applied in the direction of only measuring current, vehicle testing, vehicle impact testing, etc., can solve the problems of insufficient collision strength, unreliable locking, unusable, etc., to achieve convenient operation and sensitivity of current testing Good, good locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention:

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

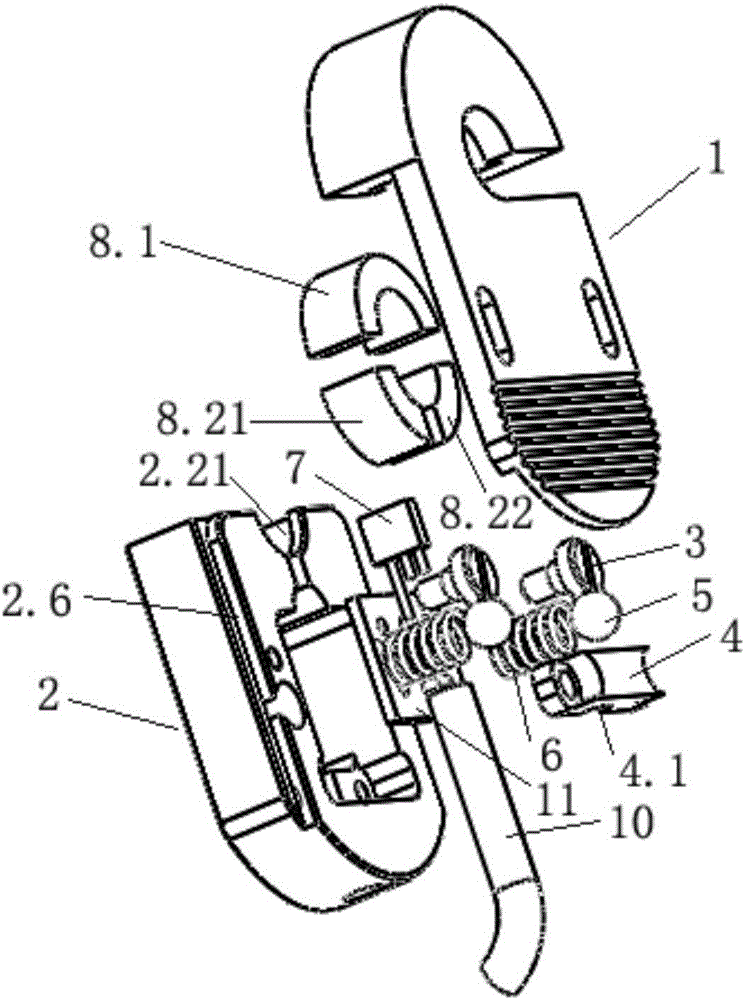

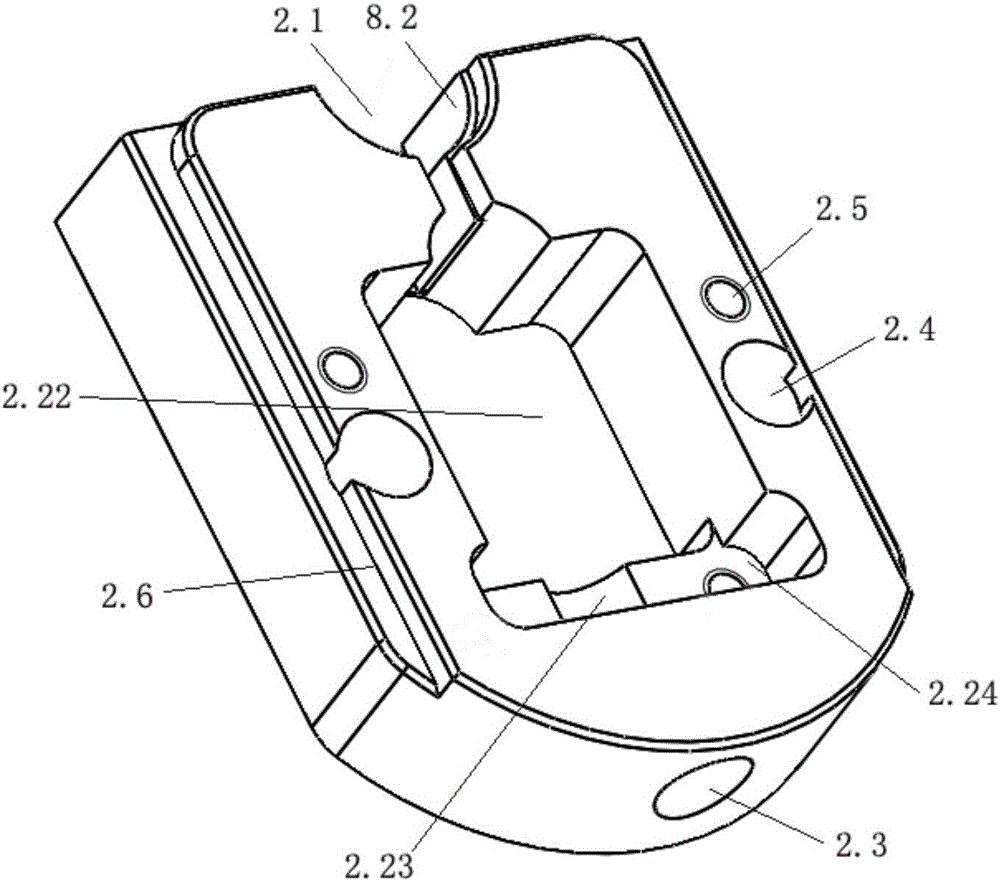

[0026] Automobile crash test current sensor according to the present invention, as Figure 1-5 As shown, it mainly includes a lower cover 2 and an upper cover 1 .

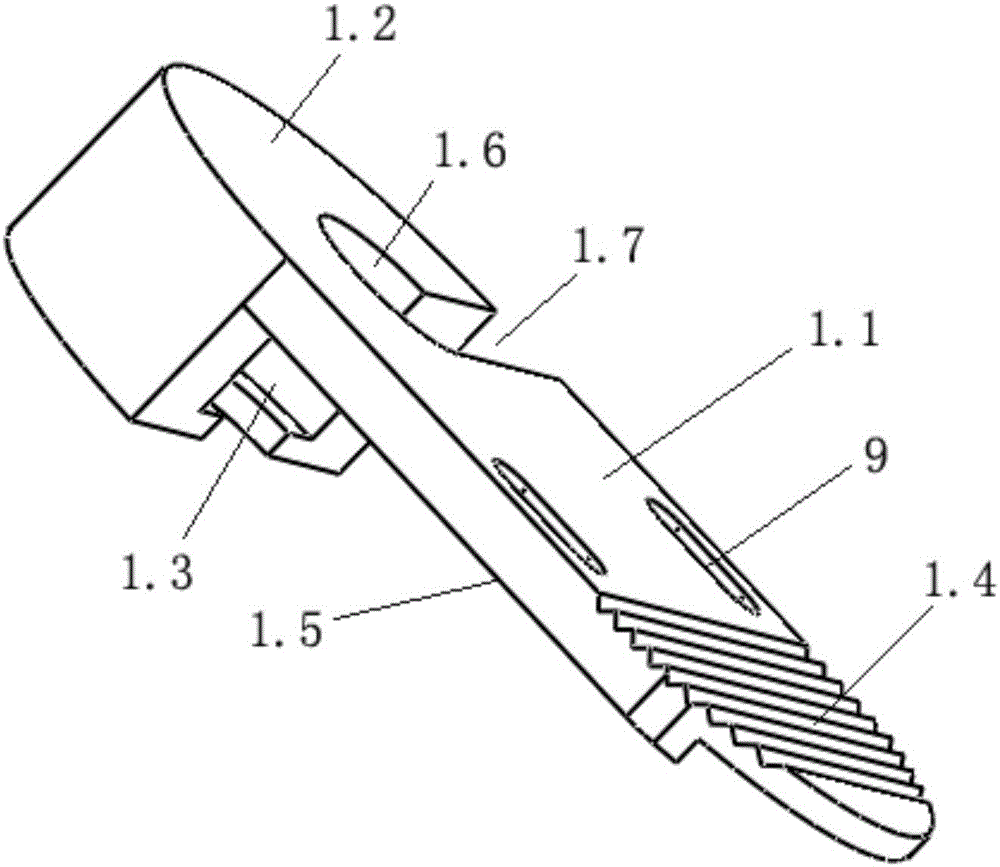

[0027] Among them, the upper cover plate 1 such as figure 2 As shown, it includes the cover part 1.1 located at the lower part and the upper magnetic ring installation part 1.2 with the upper magnetic ring 8.1 built in the upper part, and one side of the upper magnetic ring installation part 1.2 ( Figure 1-5 shown on the left side) is integrally connected with the cover part 1.1, and the other side ( Figure 1-5 Shown as the right side) and the covering part 1.1, there is a wire inlet 1.7 for wires to go in and out, and the inner side of the wire inlet 1.7 is a detection hole 1.6. The longitudinal section of the upper magnetic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com