Moving power source device for heading machine

A technology of roadheader and power source, applied in the field of mining equipment, can solve the problems of laborious transportation, can not be ignored, waste of total time when switching on and off, and save time, facilitate connection, and ensure successful control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

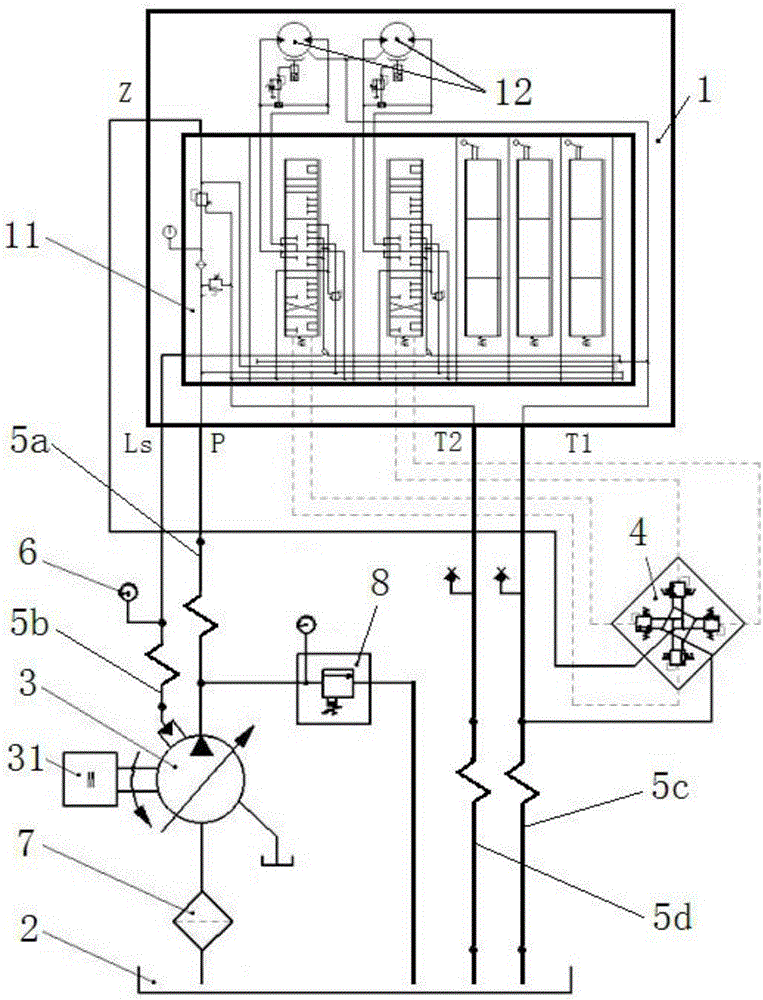

[0044] Such as figure 1 As shown, a mobile power source device for a roadheader of the present invention includes a hydraulic oil tank 2 for oil storage, a variable plunger pump 3 for oil delivery, and a travel control handle 4 for controlling the roadheader 1 to walk. The oil tank 2 is connected to the inlet of the variable displacement plunger pump 3, and the variable displacement plunger pump 3 is started by the diesel engine 31. The outlet of the variable displacement plunger pump 3 is connected to the oil inlet P of the multi-way valve 11 of the roadheader 1 through the hydraulic hose 5a, and the multi-way The signal control oil port Ls of the valve 11 is connected with the control port of the variable displacement plunger pump 3 through the hydraulic hose 5b, the first oil outlet T1 of the multi-way valve 11 is connected with the hydraulic oil tank 2 through the hydraulic hose 5c, and the multi-way valve 11 The second oil outlet T2 is connected to the hydraulic oil tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com