Rotary compressor

A technology of rotary compressor and compression chamber, applied in the field of compressors, can solve problems such as compressor performance decline, and achieve the effect of reducing impact and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

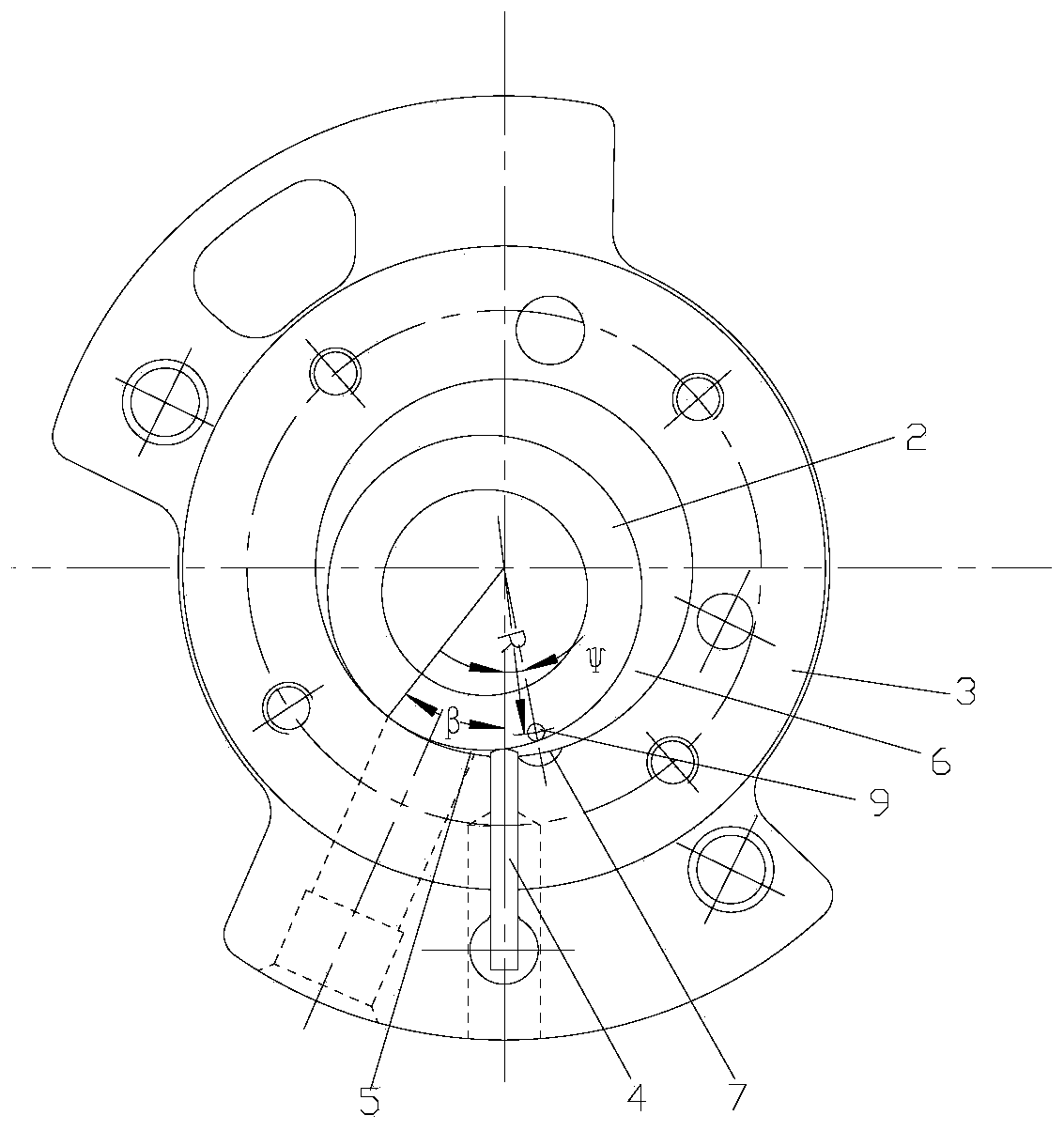

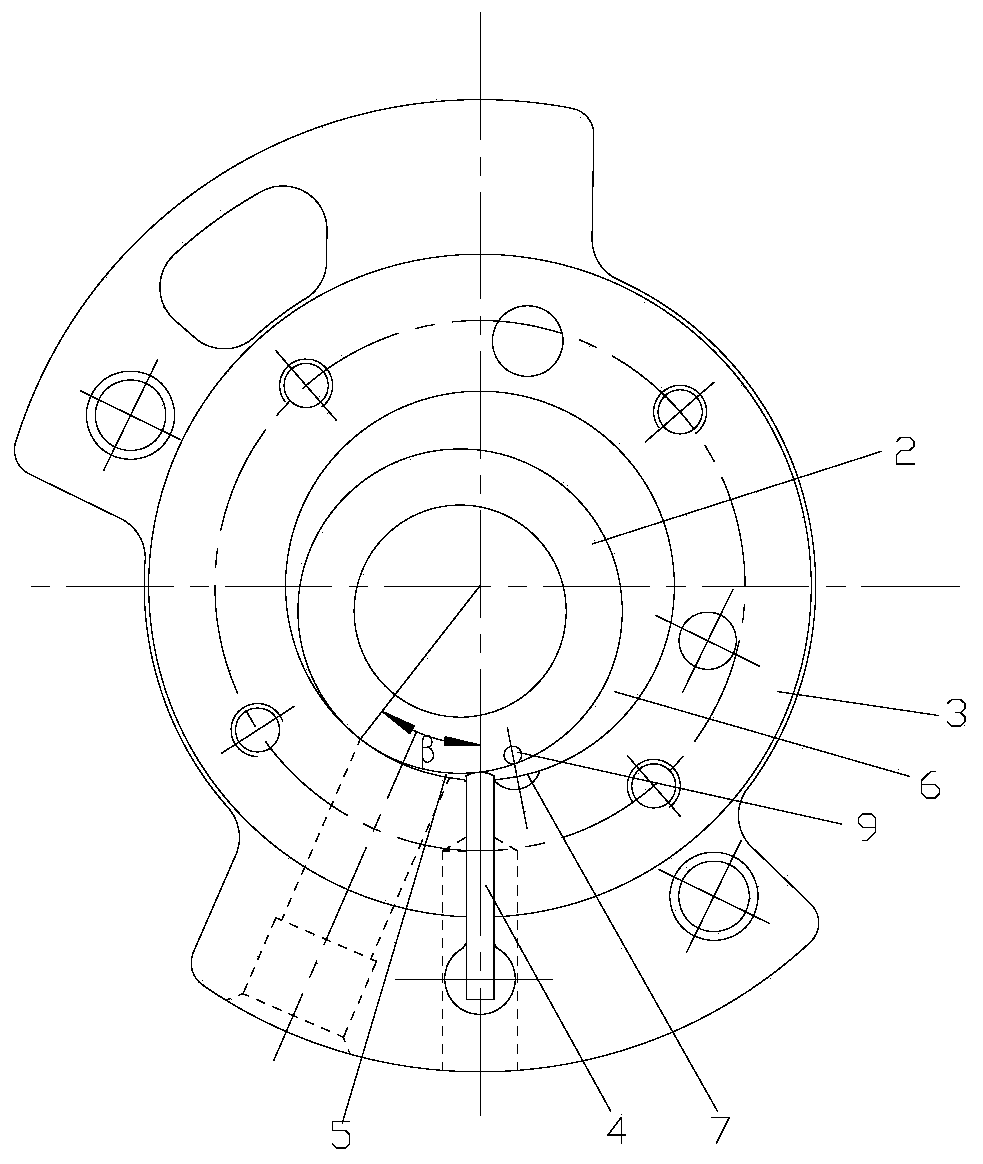

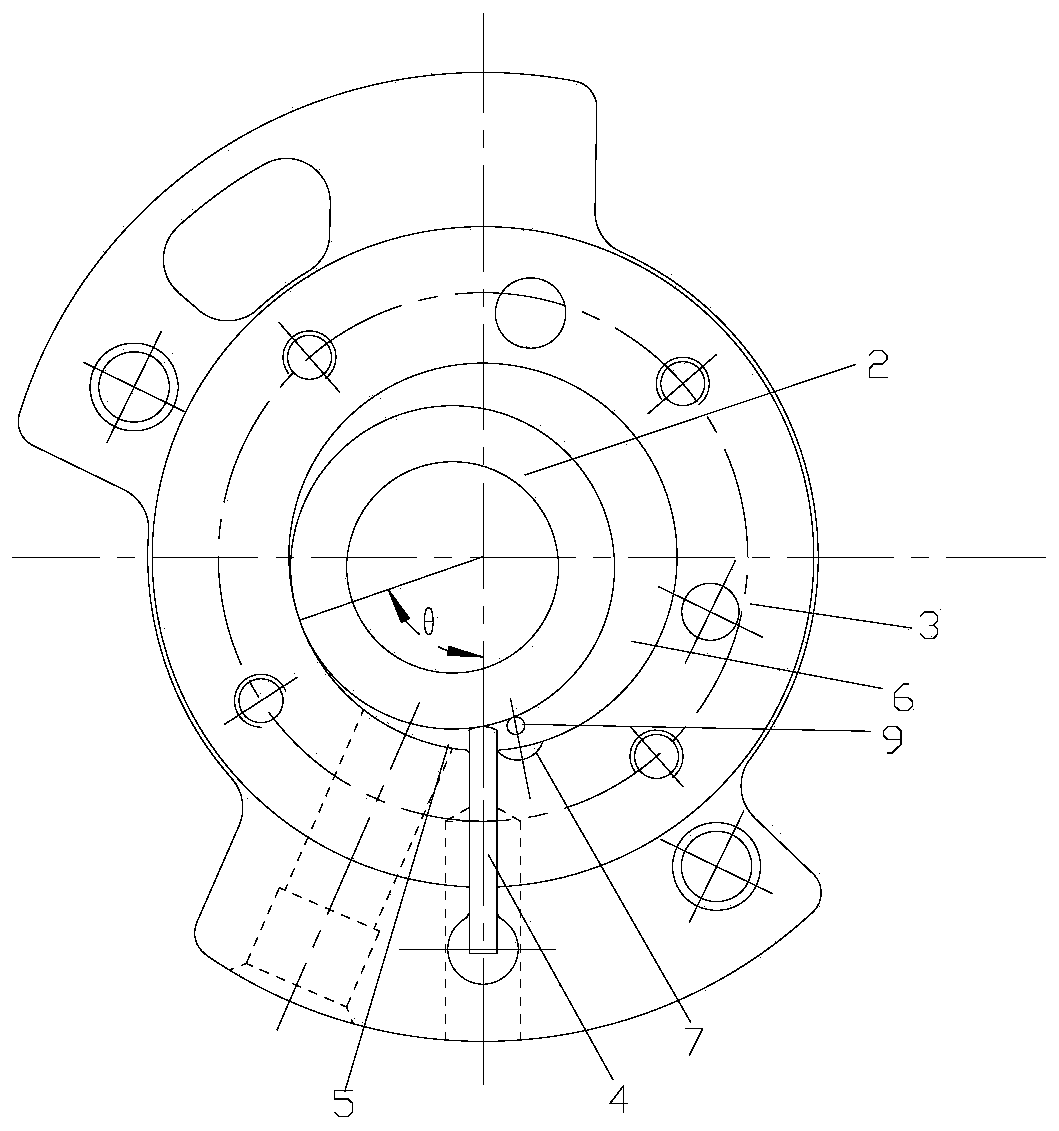

[0032] see in conjunction Figure 1 to Figure 13 As shown, according to the embodiment of the present invention, the rotary compressor includes a cylinder head plate 1, a rolling piston 2 and a pump body cylinder 3, the pump body cylinder 3 has a piston cavity, the rolling piston 2 is rollingly arranged in the piston cavity, and the pump body cylinder 3 is slidably provided with a slide plate 4, one end of the slide plate 4 abuts against the outer wall of the rolling piston 2, and divides the piston chamber into a suction chamber 5 and a compression chamber 6, and a resonant chamber 8 is provided on the cylinder head plate 1, and the pump body cylinder 3 is provided with an exhaust port 7, and the resonance chamber 8 and the compression chamber 6 are not connected when the rotary compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com