Wall plate sealing rubber strip and connecting structure for wall plates

A technology of sealing strips and connecting structures, which is applied in the direction of building construction and construction, can solve the problems of high environmental and temperature requirements, poor durability of weather-resistant sealants, and affecting the life of weather-resistant sealants, etc., to achieve simple construction technology, The effect of construction quality assurance and easy construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

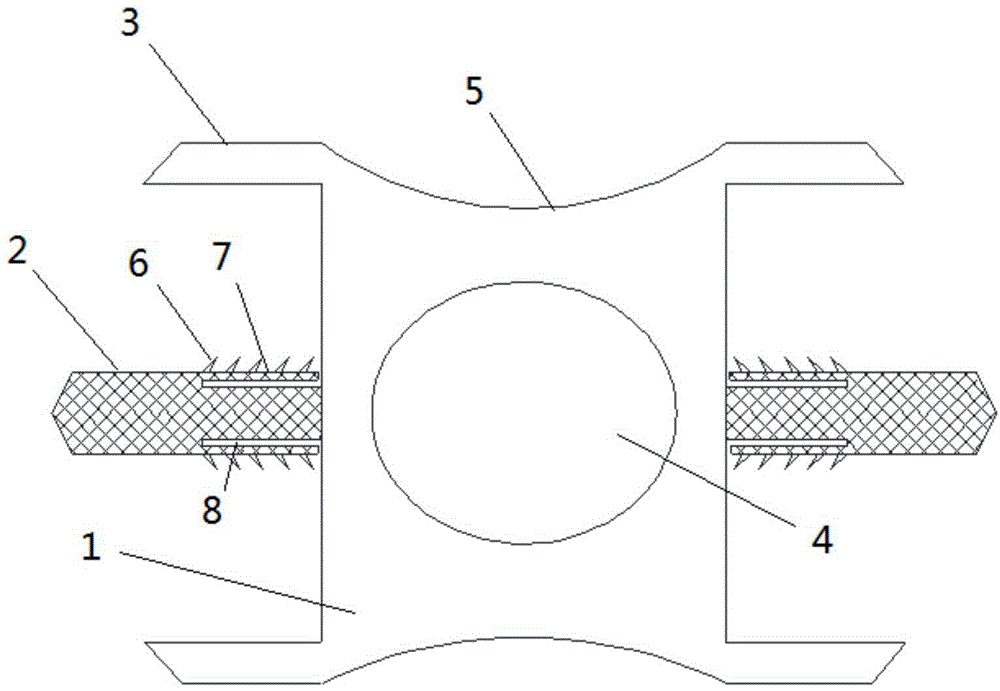

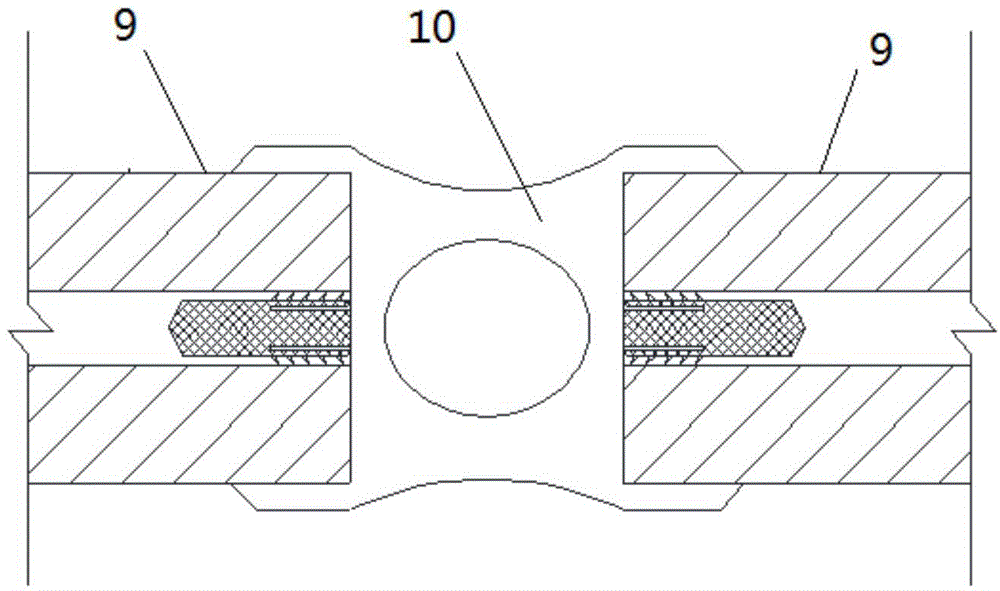

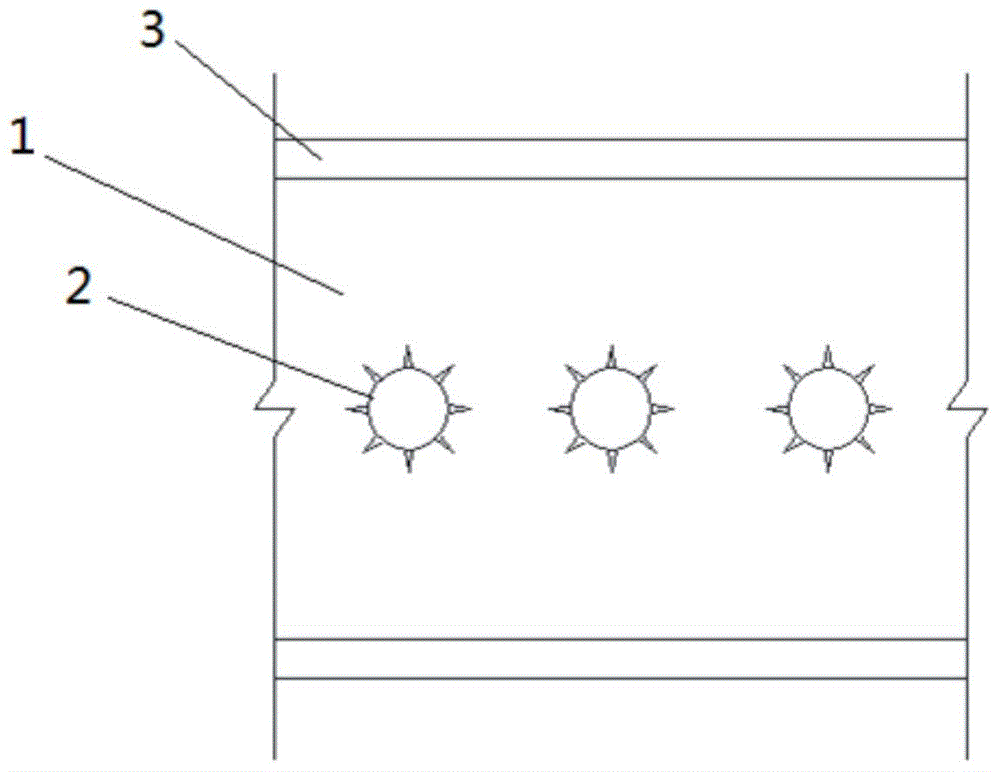

[0026] like figure 1 and image 3 As shown, a wallboard sealing strip includes a base part 1, a first sealing part 2 and a second sealing part 3, the base part 1 is a strip profile with a square or rectangular cross section, and the middle part is a hollow structure 4, The cross section of the hollow structure 4 is elliptical; the first sealing parts 2 are respectively perpendicular to the middle of the two sides of the base part 1, and extend to the outside of the base part 1, and a plurality of first sealing parts 2 can be evenly spaced on the base The middle part on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com