A method of building deflection correction and reinforcement based on anchor static pressure pile sealing technology

A technology for anchor static pressure piles and buildings, which is applied in construction, foundation structure engineering, etc. It can solve problems such as long construction period, loss of prestress, and failure to achieve the effect of deviation correction, and achieve the effect of reducing construction procedures and preventing intensification of inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

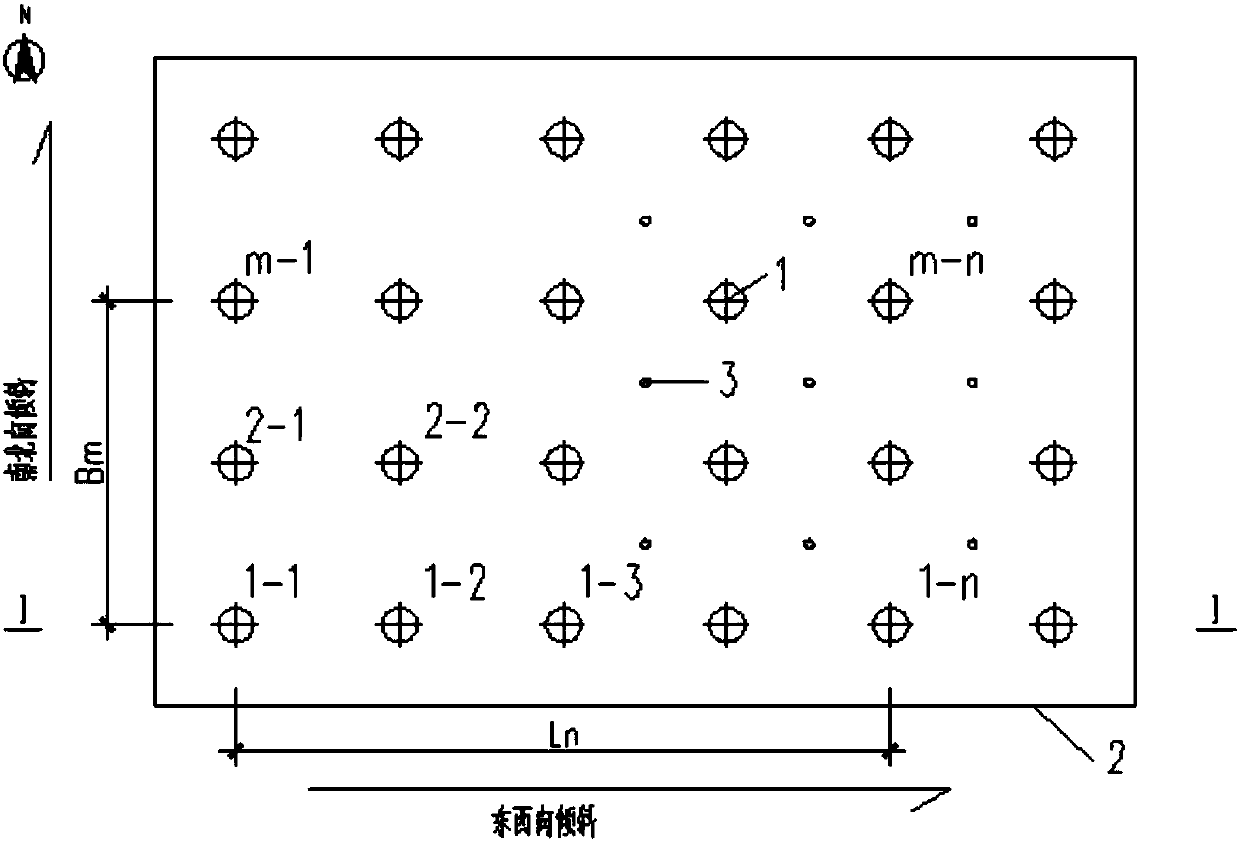

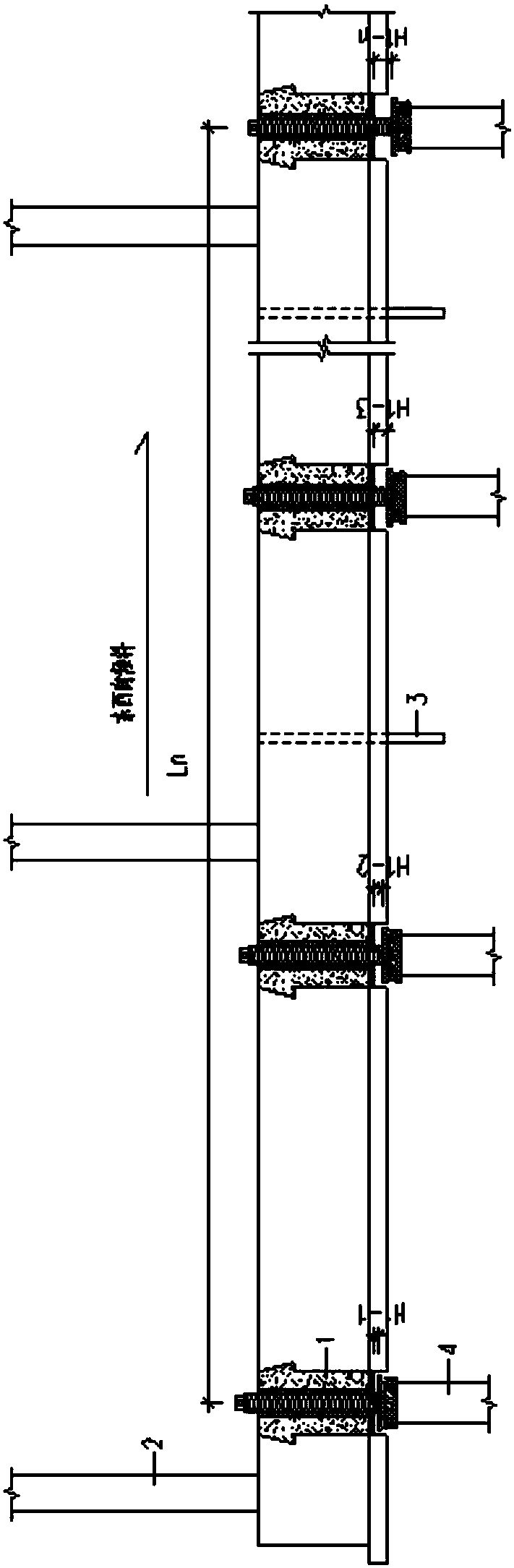

[0021] Such as figure 1 with figure 2 As shown, a method for rectifying and strengthening buildings based on static pressure pile sealing technology with anchor rods includes the following steps:

[0022] (1) Open a number of pile pressure holes 1 arranged in a matrix in the uneven settlement area of the existing building 2 .

[0023] (2) Press the anchor static pressure pile 4 into the pile pressure hole 1 to the design elevation, and pre-stress the pile for pre-sealing.

[0024] Such as image 3 As shown, the static pressure pile 4 comprises a static pressure pile body 41, an arc-shaped support 42 is welded on the top of the static pressure pile body 41, and a dividing plate 43 is placed on the top of the arc-shaped support 42 and is connected with The threaded rods 44 passing through the partition 43 are connected, and the threaded rods 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com