Single gate pier for controlling automatic rotary opening and closing of double-layer gates in four holes

A technology of automatic rotation and sluice gates, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of many obstacles in the sluice chamber, high labor cost, power consumption, etc., to improve hydraulic technology, save labor cost, and maintain convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

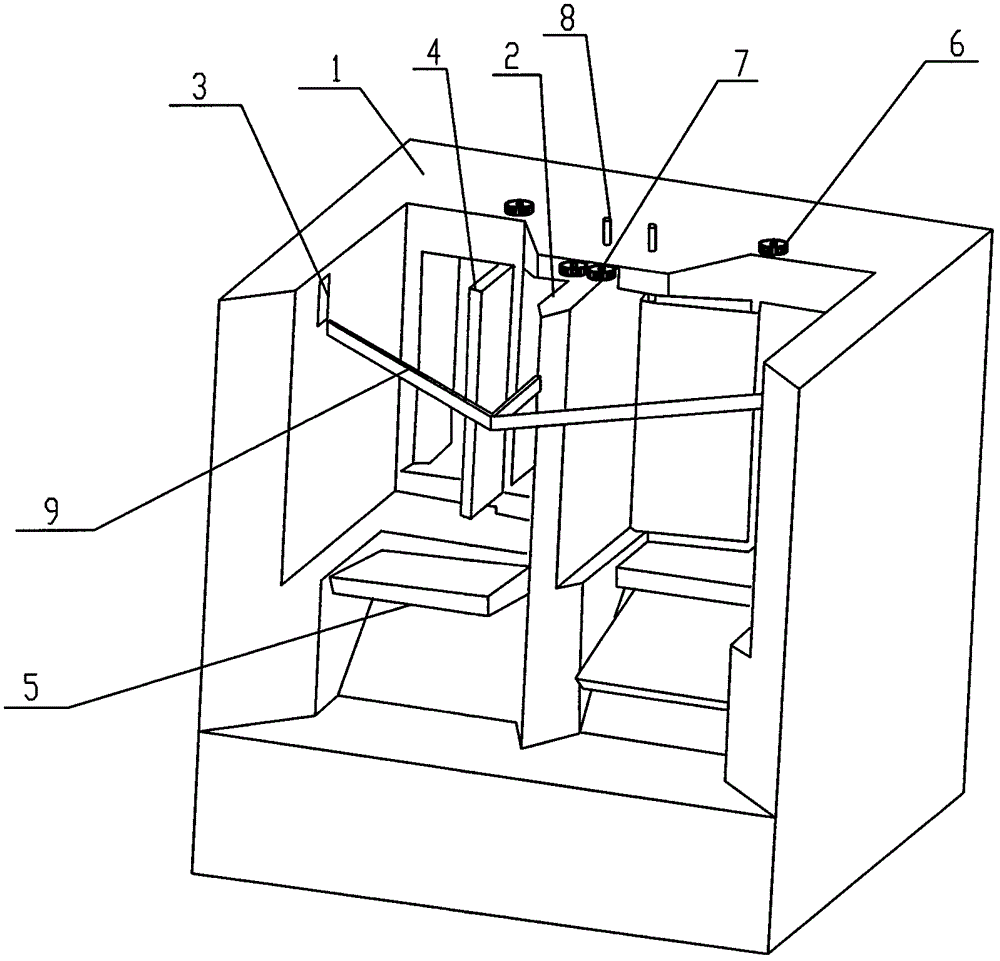

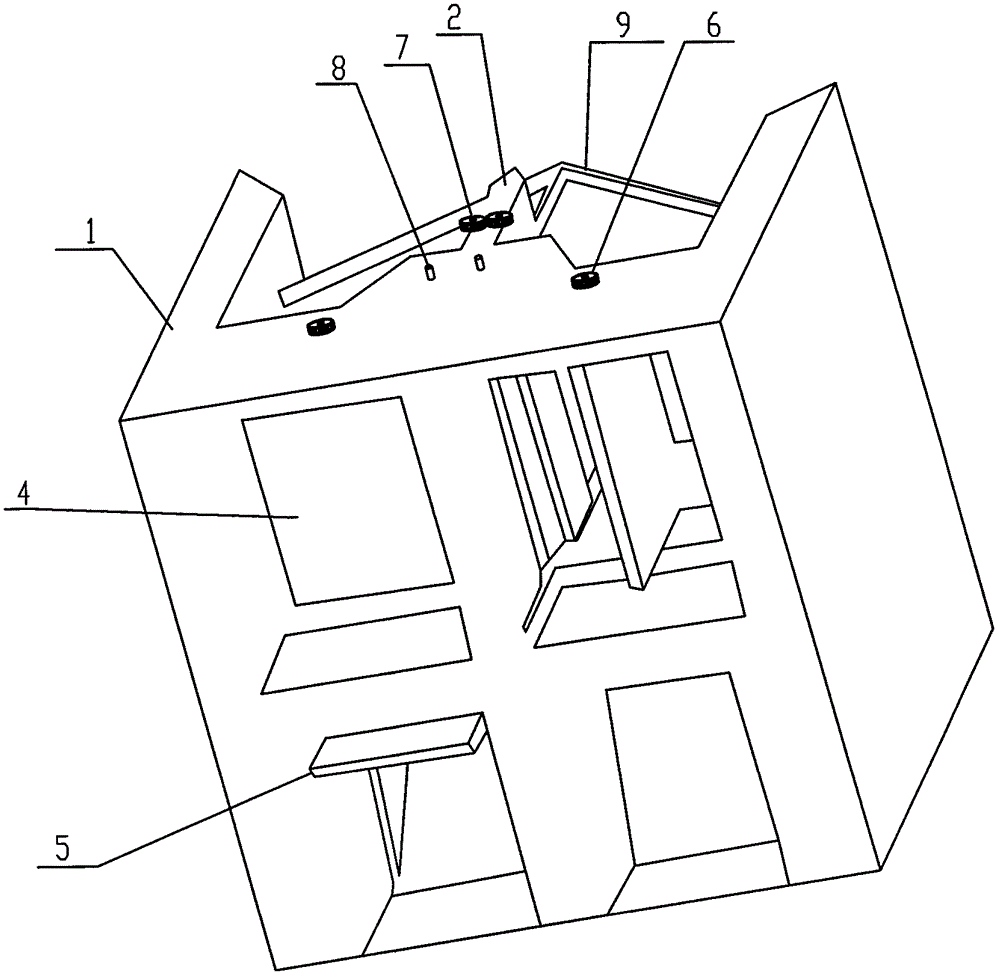

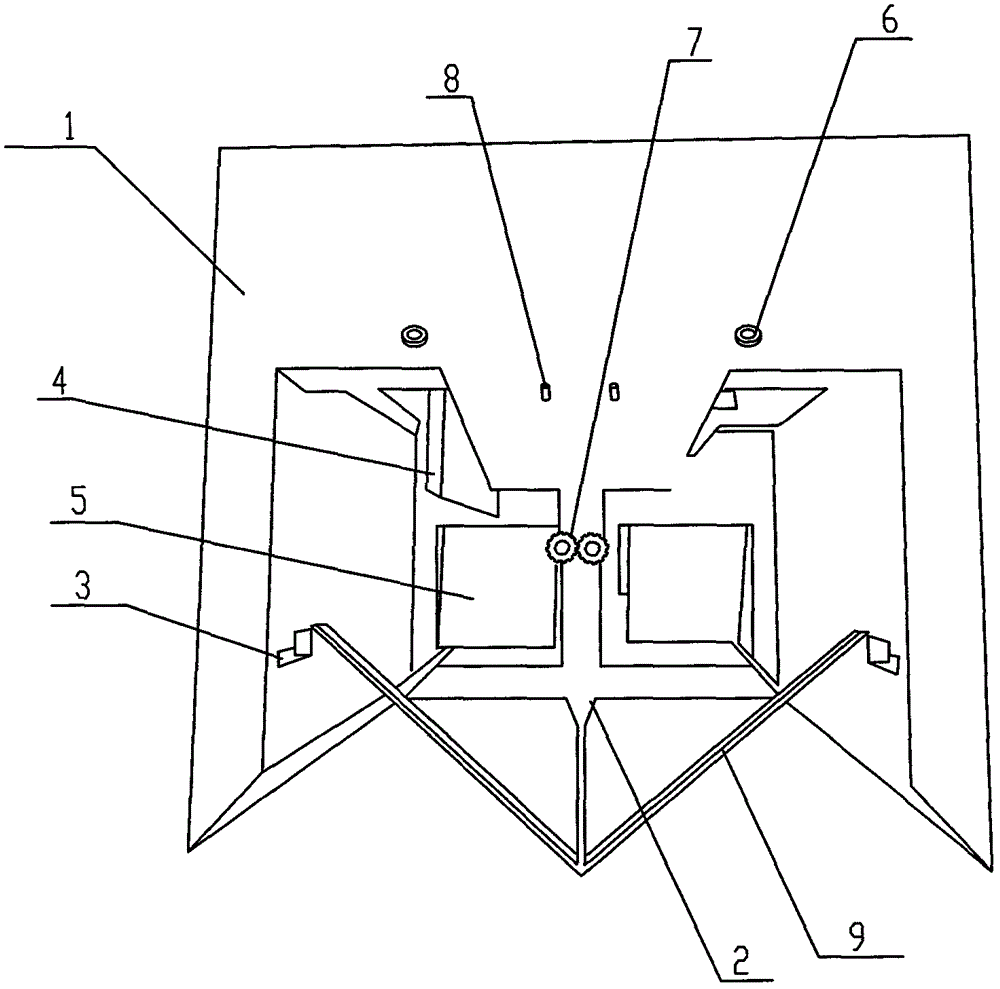

[0018] like Figure 1-4 As shown, the automatic rotary switch of the double-deck four-hole gate controlled by the single gate pier of the present invention includes the main gate and the control mechanism on the gate wall 1 and the gate pier 2, and the rear side of the main gate is also provided with a switch door and a supporting point; The gate pier 2 is provided with one, which is located in the center between the gate walls 1, and the gate walls on both sides of the gate pier 2 are provided with overflow outlets 3 for filtering garbage on the water surface. The moraine gate 5, the plane gate 4 and the moraine gate 5 have a transverse interlayer; the control mechanism includes a control automatic switch arranged on a gate pier 2, a gear 6 linked with the upper plane gate 4, and a moraine discharge gate on the lower level. The shrinkage cable and the gear set 7 linked by the gate 5. The plane gate 4 is opened and closed left and right through the rotation of the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com