Scheelite decomposing method

A technology of scheelite and decomposition reaction, which is applied in the direction of improving process efficiency, etc., can solve the problems of scheelite wrapping and affecting decomposition rate, etc., and achieve the effect of obvious synergy, clean operating environment and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

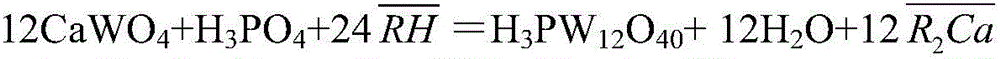

Method used

Image

Examples

Embodiment 1

[0027] Mix 9.6g of pretreated (conventional acidification process) 732 resin, 0.24mL of phosphoric acid with a mass fraction of 85%, and 300mL of water into a 1L reaction vessel, stir and heat to 30°C, then add 10g of scheelite (including WO 3 49.75%, containing Ca8.72%), start timing, finish the reaction after 2 hours, vacuum filter, send the filtrate to ICP, and the decomposition rate of tungsten is 96.4%.

Embodiment 2

[0029] Mix 9.6g of pretreated 732 resin, 0.36mL of phosphoric acid with a mass fraction of 85%, and 200mL of water into a 1L reaction vessel, stir and heat to 40°C, then add 10g of scheelite (containing WO 3 49.75%, containing Ca8.72%), start timing, finish the reaction after 1h, vacuum filter, send the filtrate to ICP, and the decomposition rate of tungsten is 98.2%.

Embodiment 3

[0031] Mix 14.4g of pretreated 732 resin, 0.12mL of phosphoric acid with a mass fraction of 85%, and 200mL of water into a 1L reaction vessel, stir and heat to 60°C, then add 10g of scheelite (containing WO 3 49.75%, containing Ca8.72%), start timing, finish the reaction after 3 hours, vacuum filter, send the filtrate to ICP, and the decomposition rate of tungsten is 94.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com