Conveyor

A conveyor and fixed base technology, applied in the field of conveyors, can solve the problems of workers having nothing to do, workers working overtime, passive production of enterprises, etc., and achieve the effect of solving production restrictions, reducing production idleness, and reducing production busyness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

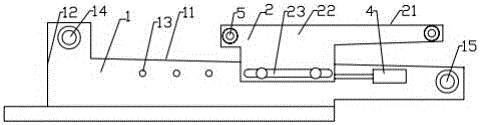

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] A conveyor, comprising a fixed base 1 and an adjustable base 2 arranged on the top of the fixed base 1, the left side plate 11 and the right side plate 12 of the fixed base 1 are respectively provided with threaded connection holes 13, the adjustable base 2 The left side plate 21 and the right side plate 22 are respectively provided with a waist-shaped hole 23, and the waist-shaped hole 23 is fixed with a connecting bolt 3, and the said connecting bolt 3 is fixed on the threaded connection hole 13 through the waist-shaped hole 23, The front end of the fixed base 1 is provided with a transmission shaft 14, and the tail is provided with a driven shaft 15.

[0012] The adjustable base 2 can easily adjust its relative length to the fixed base 1 through the length of the waist-shaped hole 23. Specifically, the length of the connecting material between the transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com