Efficient cotton bale labeling system of spray-head and platform all-in-one machine

A cotton bale labeling and all-in-one machine technology, applied in packaging, printing machines, rotary printing machines, etc., can solve the problems of cotton bale pollution, high error rate, high labor intensity, etc., and achieve precise rotation at any angle and precise horizontal movement , The effect of convenient and safe sewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

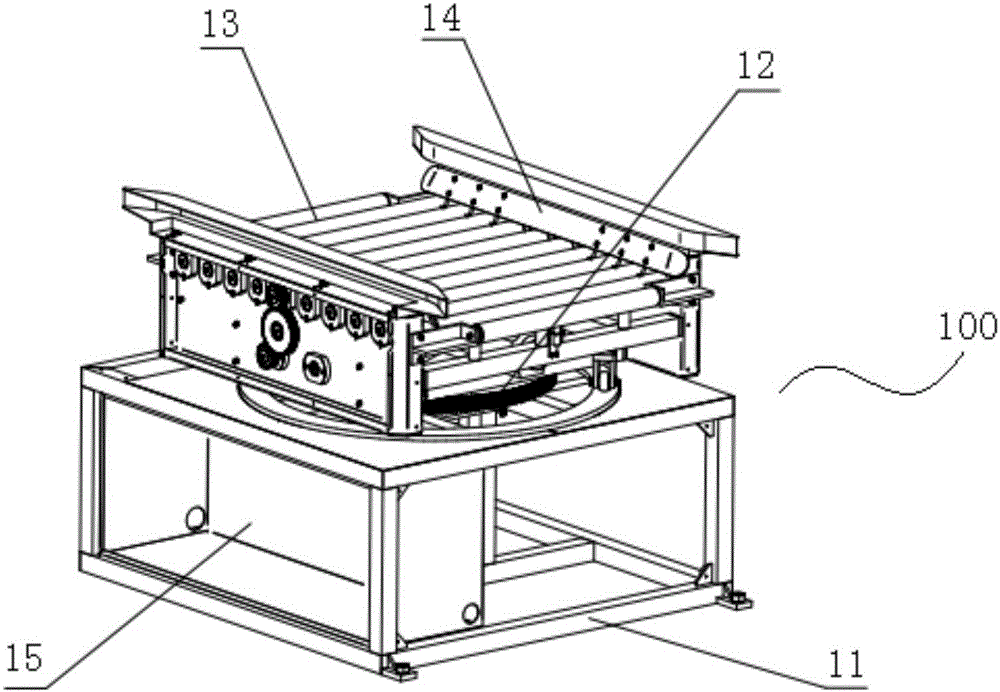

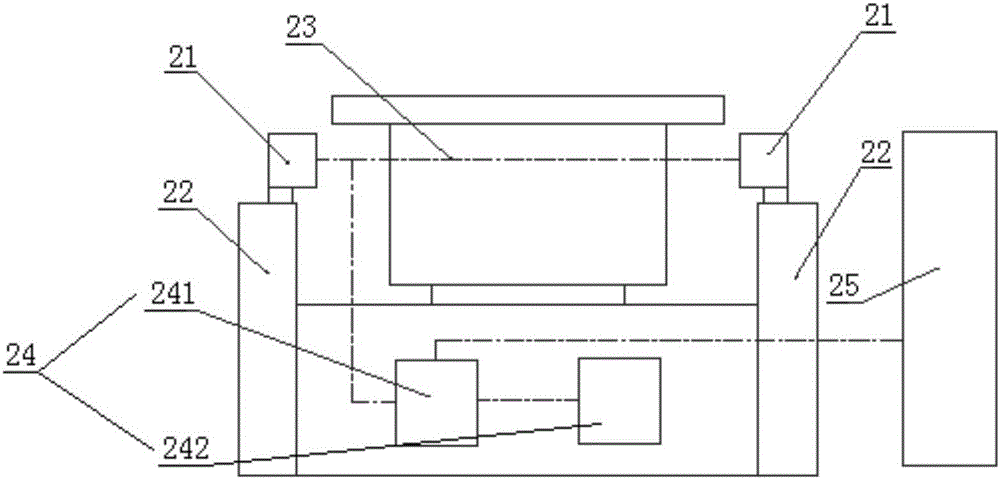

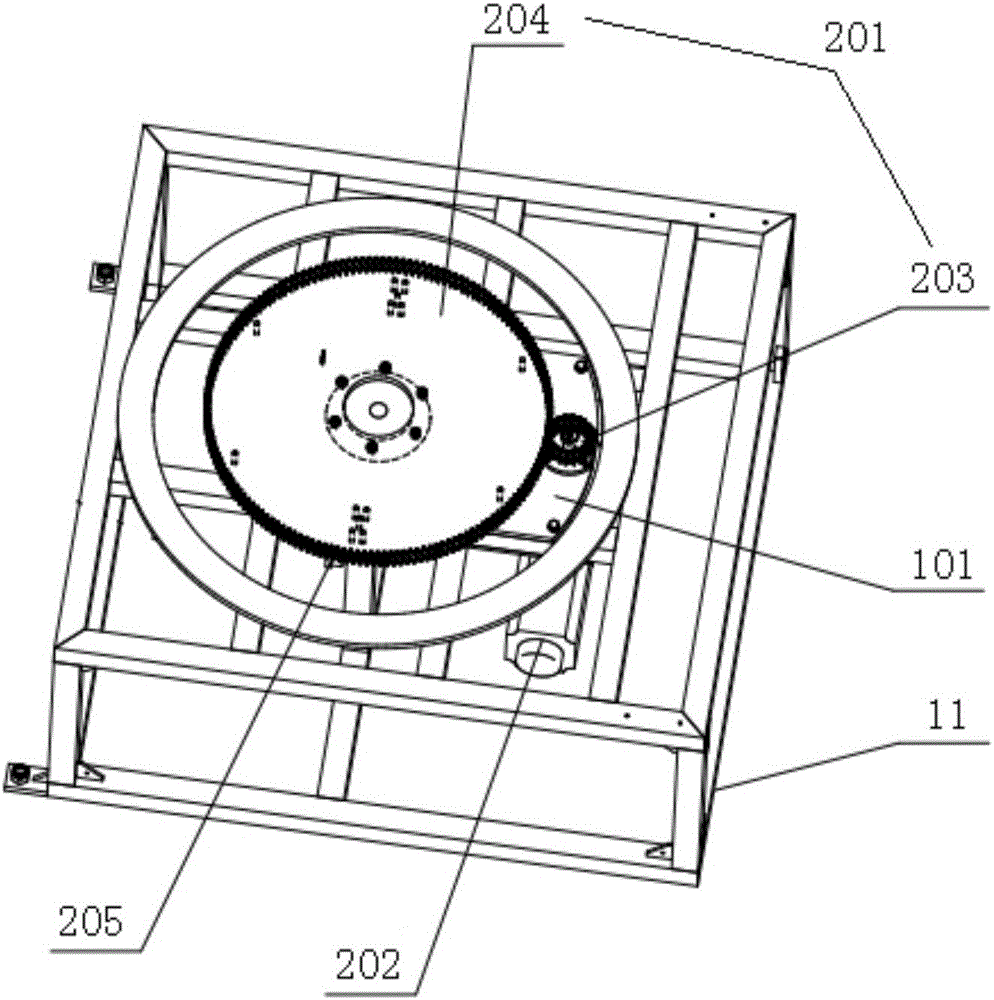

[0035] like figure 1 , figure 2 As shown, the double-nozzle fast cotton bale marking system provided in this embodiment includes a subcontracting platform 100 and an automatic marking device 200 located on one side or both sides of the subcontracting platform 100 .

[0036] The subcontracting platform 100 includes a platform support frame 11 , a subcontracting device 12 , a package delivery device 13 , a package checking device 14 and an automatic control device 15 . The bag checking device 14 is installed on the bag transporting device 13 , the bag transporting device 13 is installed on the subcontracting device 12 , and the subcontracting device 12 is installed on the platform support frame 11 . After the cotton bale enters the bag transporting device 13, the platform automatic control device 15 starts the bag transporting device 13 to detect the position of the cotton bag in real time, and when the cotton bag reaches the designated position, the bag transporting device 13...

Embodiment 2

[0070] The fast cotton bale automatic swabbing system provided by this embodiment is basically the same in structure as that of Embodiment 1, the difference is that: Embodiment 1 uses a submerged nozzle driving mechanism 22, while the suspended nozzle driving mechanism 22 in this embodiment 300.

[0071] like Figure 10 , Figure 11 As shown, the suspended spray head driving mechanism 300 is mainly composed of a fixed frame 311 , an X-direction slide mechanism 312 , a Y-direction slide mechanism 313 , a Y-axis motor 314 and an X-axis motor 315 . Wherein, the X-direction slide mechanism 312 and the Y-direction slide mechanism 313 have the same structure, and both are composed of a frame 401 , a guide rail 402 , a lead screw 403 and a loading bracket 404 . The guide rail 402 and the lead screw 403 are installed on the frame 401, and play the roles of guiding and transmission respectively. The loading bracket 404 is connected with the guide rail 402 and the lead screw 403 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com