Gas supply control device of forming machine main drum driving box

A control device and drive box technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of inconvenient installation and replacement, the number of rotary seals, and the number of rotary seals used, so as to reduce the difficulty of processing and assembly. , The effect of reducing the frequency of replacement and reducing the cost of equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

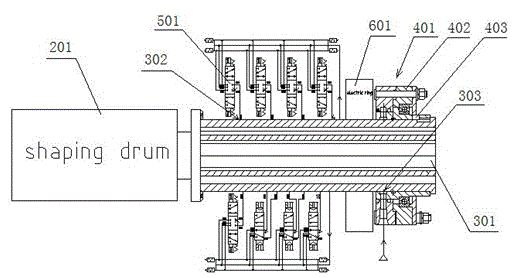

[0021] Embodiment 1, the air supply control device for the main drum drive box of the molding machine in this embodiment, such as figure 2 As shown, it includes a main shaft 301 with one end connected to the main drum drive box 201 of the molding machine. The main shaft 301 is provided with a plurality of ordinary inner holes 302 connected with the forming drum through the internal air passage of the main shaft 301 and an air source inner hole 303. The periphery of the air source inner hole 303 is provided with a rotary seal 401, the rotary seal 401 is connected to the air source (not shown in the figure), each of the common inner holes 302 is respectively connected to a solenoid valve 501, each of the The inlet end of the electromagnetic valve 501 is connected with the inner hole 303 of the air source through an air path. The working principle of this air supply control device is: the air source supplies air to the inner hole 303 of the air source through the rotary seal, an...

Embodiment 2

[0025] Embodiment two, such as image 3 As shown, this embodiment provides another structure of the air supply control device for the main drum drive box of the molding machine, which includes a main shaft 301 connected to the main drum drive box 201 of the molding machine at one end, and a plurality of passing main shafts are opened on the main shaft 301. 301, the ordinary inner hole 302 connected with the forming drum and an air source inner hole 303, the outer periphery of the air source inner hole 303 is provided with a rotary seal 401, and the rotary seal 401 is connected with the air source (not shown in the figure) ) connection, the common inner holes 302 are respectively connected to a solenoid valve 501, and the air intake end of each solenoid valve 501 is connected to the inner hole 303 of the air source through an air path. The difference from the first embodiment is that The outer surface of the main shaft 301 is fixed with a wireless receiving device 701 for recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com