A hexagon socket screw fastener

A screw tightening and screw technology, applied in screwdrivers, manufacturing tools, wrenches, etc., can solve the problems that the wrench cannot be rotated 360°, the tightening process is time-consuming and laborious, etc., to ensure the service life, facilitate lubrication, and facilitate the operation of the wrench.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

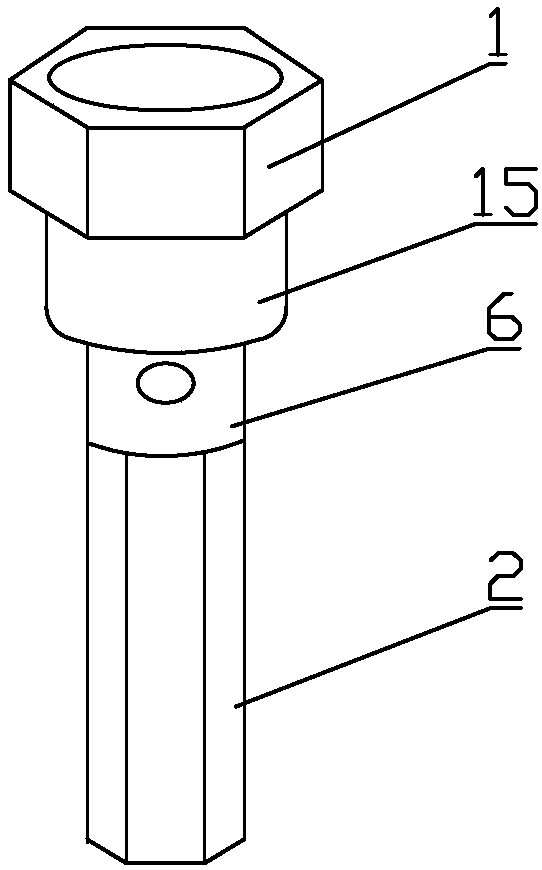

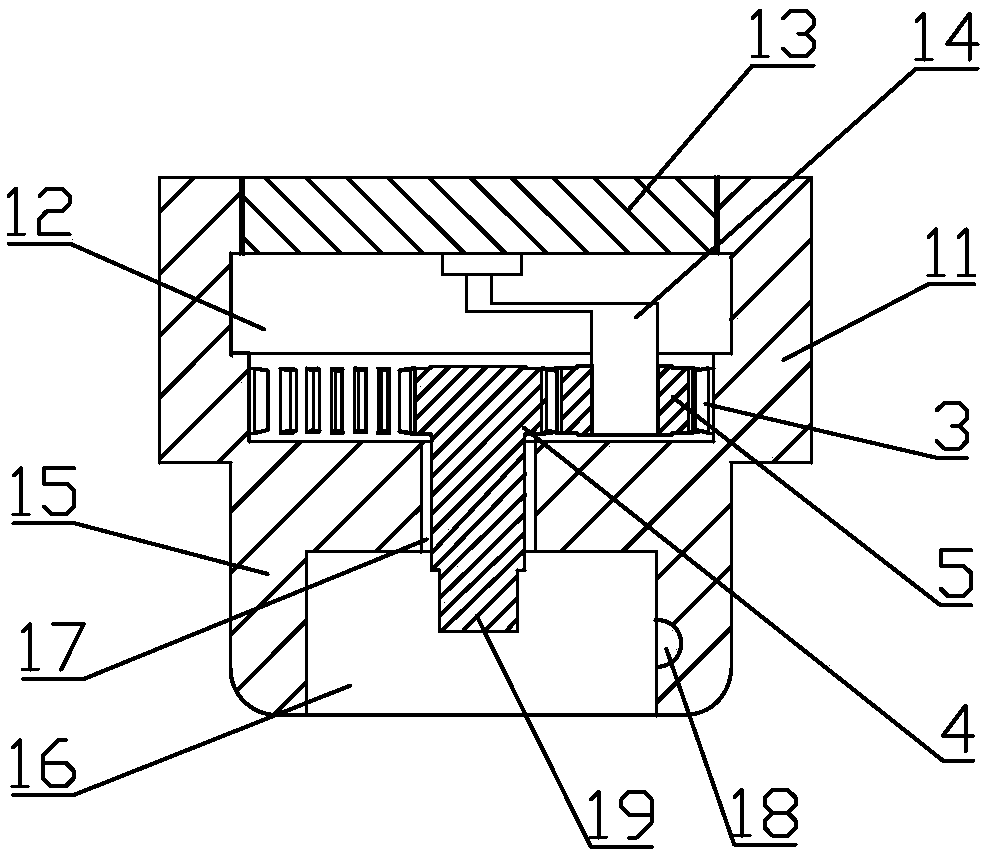

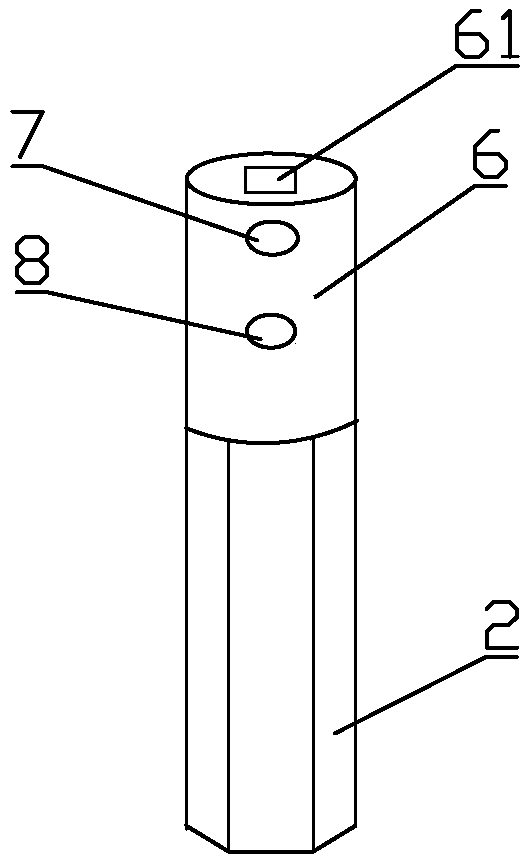

[0028] The invention provides a hexagon socket screw fastener, such as figure 1 and figure 2 As mentioned above, it includes a rotary cap 1 and a hexagonal column 2. The rotary cap 1 is used to extend into the fastening groove of the wrench to drive the rotary cap 1 to rotate. It includes an inner ring gear 3, a sun gear 4, and a planetary gear 5 meshing with both the inner ring gear 3 and the sun gear 4. The inner ring gear 3 is arranged on the rotating cap 1, and the sun gear 4 is rotatably connected to the rotating cap 1. The sun gear 4 is detachably connected with the hexagonal column 2, and the inner ring gear 3 drives the sun gear 4 to rotate through the planetary gear 5 to make the hexagonal column 2 rotate. On the one hand, the rotary cap 1 is detachably connected to the hexagonal column 2, which is convenient for replacing the hexagonal column 2 of different lengths and radial dimensions, not only suitable for occasions where the installation of hexagonal socket hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com