Flexible automatic production line system of engine cylinder covers

An automatic production line and cylinder head flexible technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of long standby time, low transmission efficiency of processed parts, etc., achieve good positioning effect, shorten average waiting time, repeat Effect of shortened transmission length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

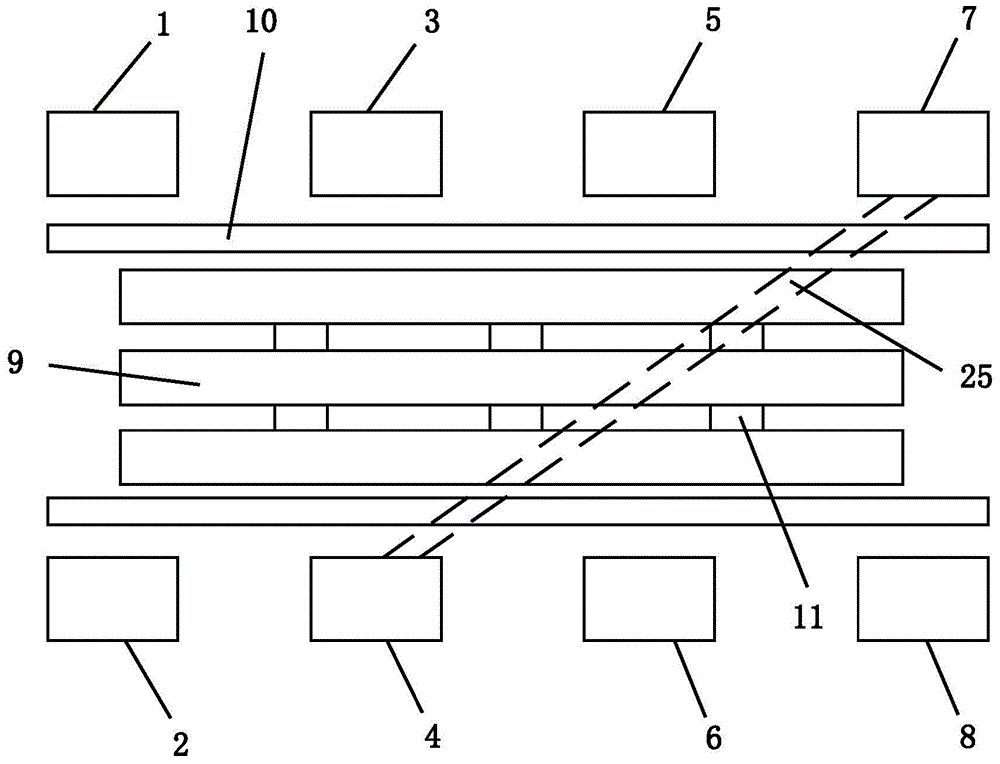

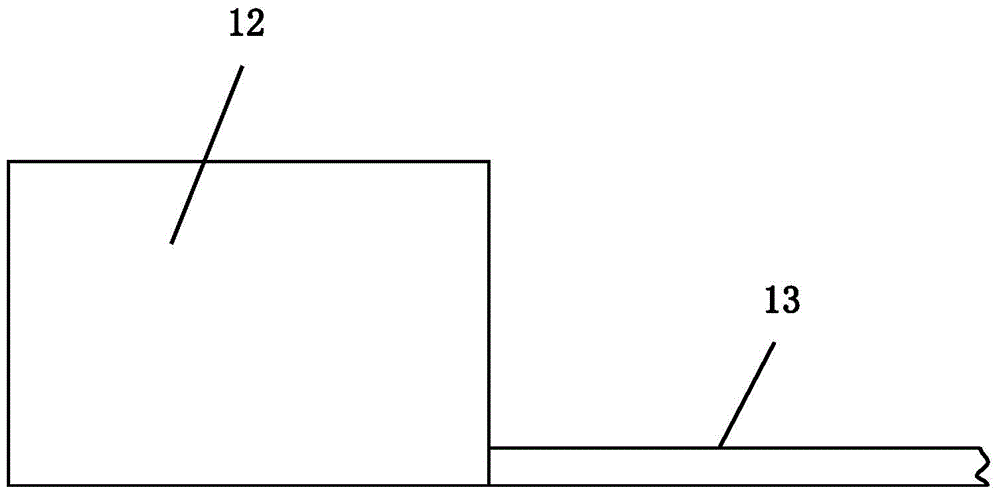

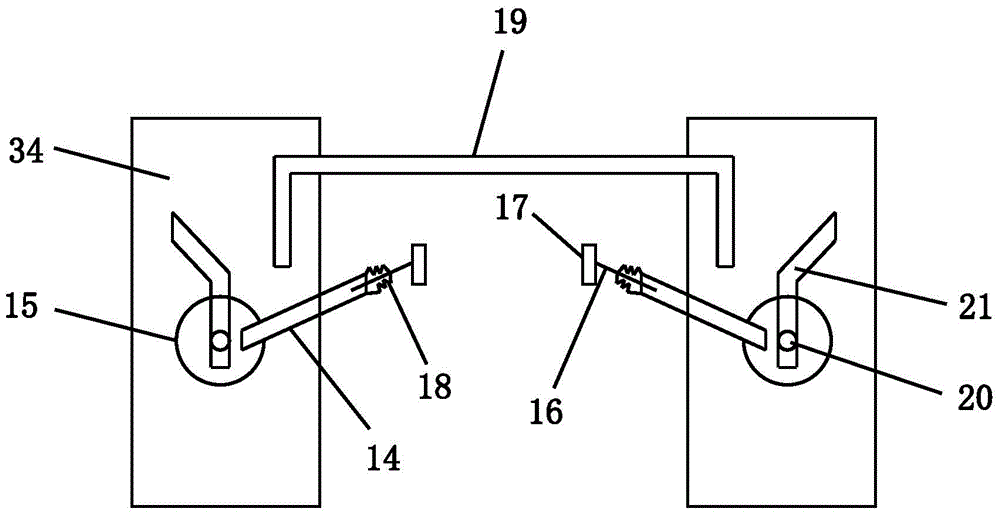

[0020] refer to Figure 1-6 , a specific embodiment of the present invention includes a rough turning outer circle module 1, a boring inner hole module 2, a correction turning module 3, a fine boring inner hole module 4, a semi-finishing machining module 5, a rough honing grinding module 6, a finishing turning module The waterway module 7 and the spiral umbrella honing module 8, in which the rough turning outer circle module 1, the correction turning module 3, the semi-finishing module 5 and the finishing turning waterway module 7 are located in the same row, the boring inner hole module 2, and the fine boring inner hole module 4. The rough honing module 6 and the spiral umbrella honing module 8 are located in the same row. A transfer area is set between the two rows of equipment. A joint walking robot 10 is arranged next to each processing module. Several parts are temporarily arranged in the transfer area. A transfer device 11 is set between the storage area 9 and the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com