Die replacing device

A technology for feeding molds and molds, applied in the field of mold changing devices, which can solve the problems of high labor intensity, increased costs, and long mold changing time, etc., and achieve the effects of easy design and implementation, faster replacement speed, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0042] The present invention will be described in detail below with reference to the accompanying drawings and examples.

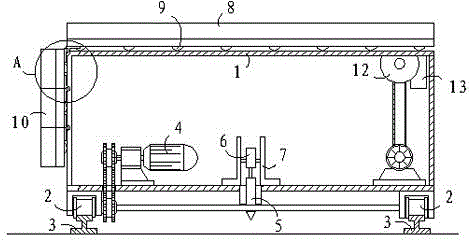

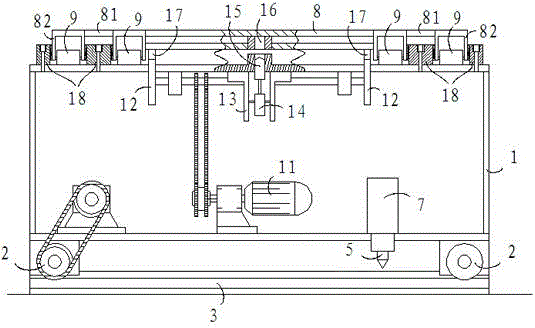

[0043] The invention relates to a mold changing device, which is used for quick mold replacement on the working table of a press, so as to improve the work efficiency of mold changing. The mold changing device includes a jacking mechanism arranged on the press workbench to lift the mold placed above the press workbench, and also includes symmetrically arranged on both sides of the press workbench and the press machine. The jacking mechanism on the workbench cooperates to carry out the mold feeding mechanism and the mold unloading mechanism for the mold feeding or unloading operation.

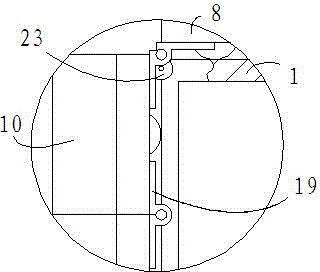

[0044] The structure of the mold feeding mechanism in this embodiment is as follows: Figure 2 to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com