Position feedback device for working roller of multi-roller mill and position feedback control method of position feedback device

A positioning feedback and control method technology, applied in the rolling field of continuous rolling mills, can solve problems such as equipment failure, product quality, unbalanced load, broken strip shape, hidden dangers, etc., to meet the needs of normal work and ensure stability and continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

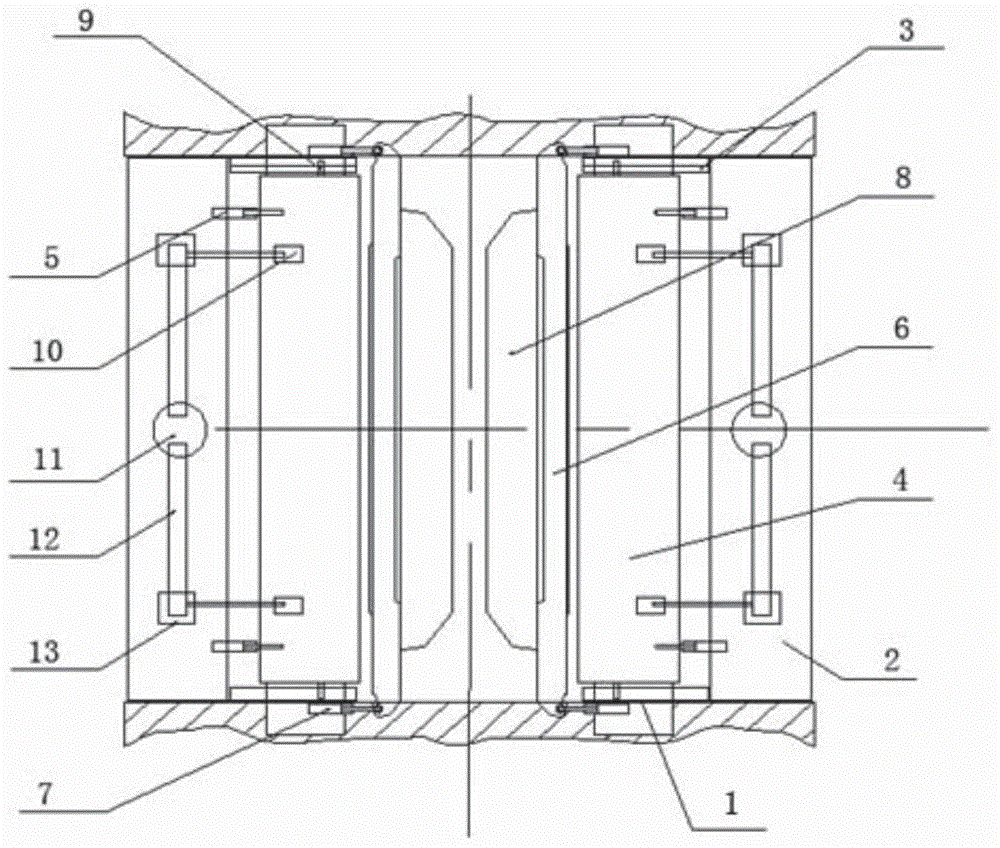

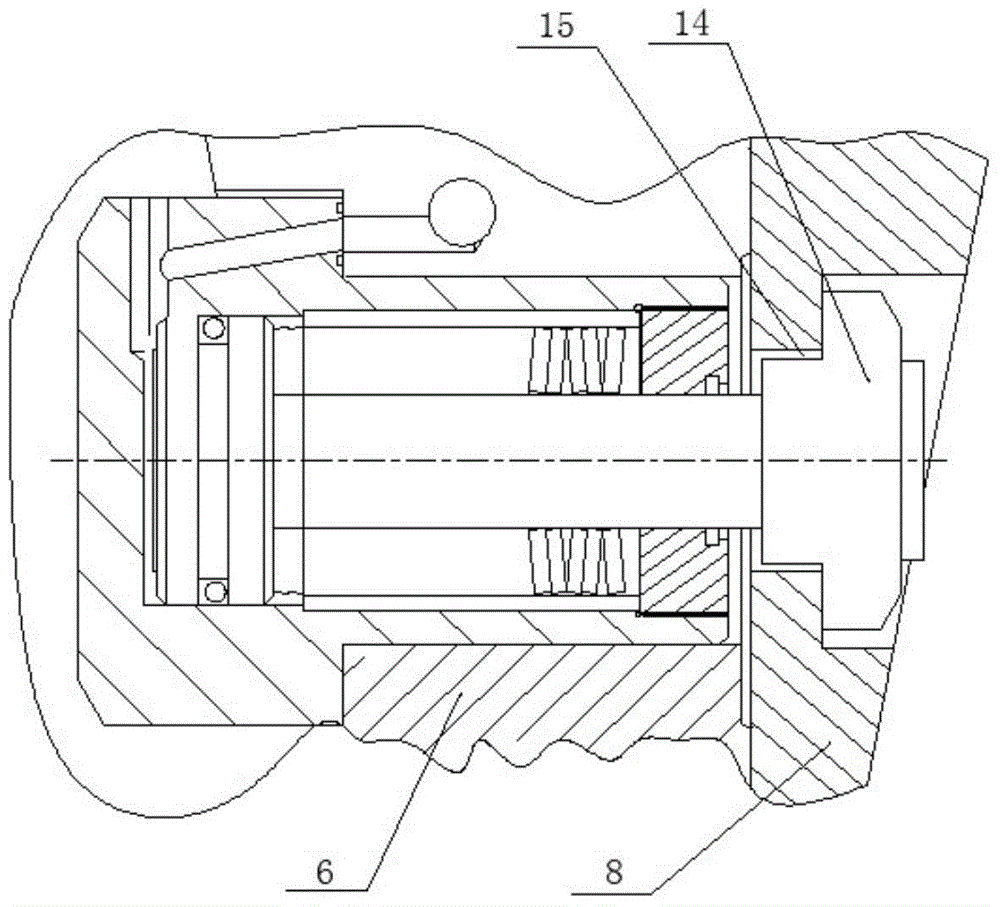

[0081] Next, a positioning feedback device for work rolls of a multi-roll rolling mill and a positioning feedback control method thereof according to the present invention will be further described in detail according to the accompanying drawings and specific embodiments.

[0082] Such as figure 1 , 2 A positioning feedback device for the work rolls of a multi-roll rolling mill is shown, which is used to adjust the positioning of the roll system after the roll change and before the roll test, so as to realize effective support for the roll system, including: located on the center line of the stand in the up and down, front and rear Four identical mechanisms arranged in mirror symmetry, each of which includes:

[0083] a transition plate (1) arranged on the frame,

[0084] a fixed arm (2) detachably fixed on the transition plate,

[0085] The linear guide rail (3) set on the transition plate,

[0086] Traversing arm (4) arranged in the linear guide rail,

[0087] Traverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com