Scraper device for concrete brick pallet

A technology for concrete and brick laying, which is applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

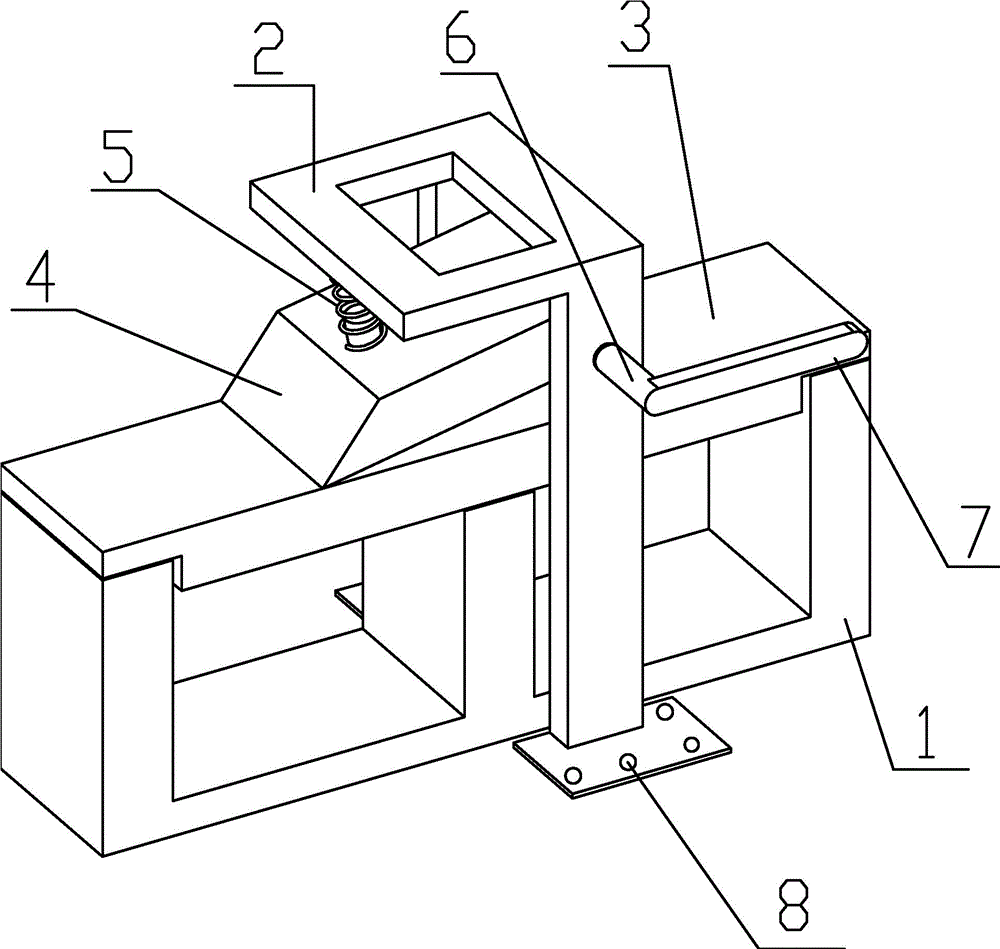

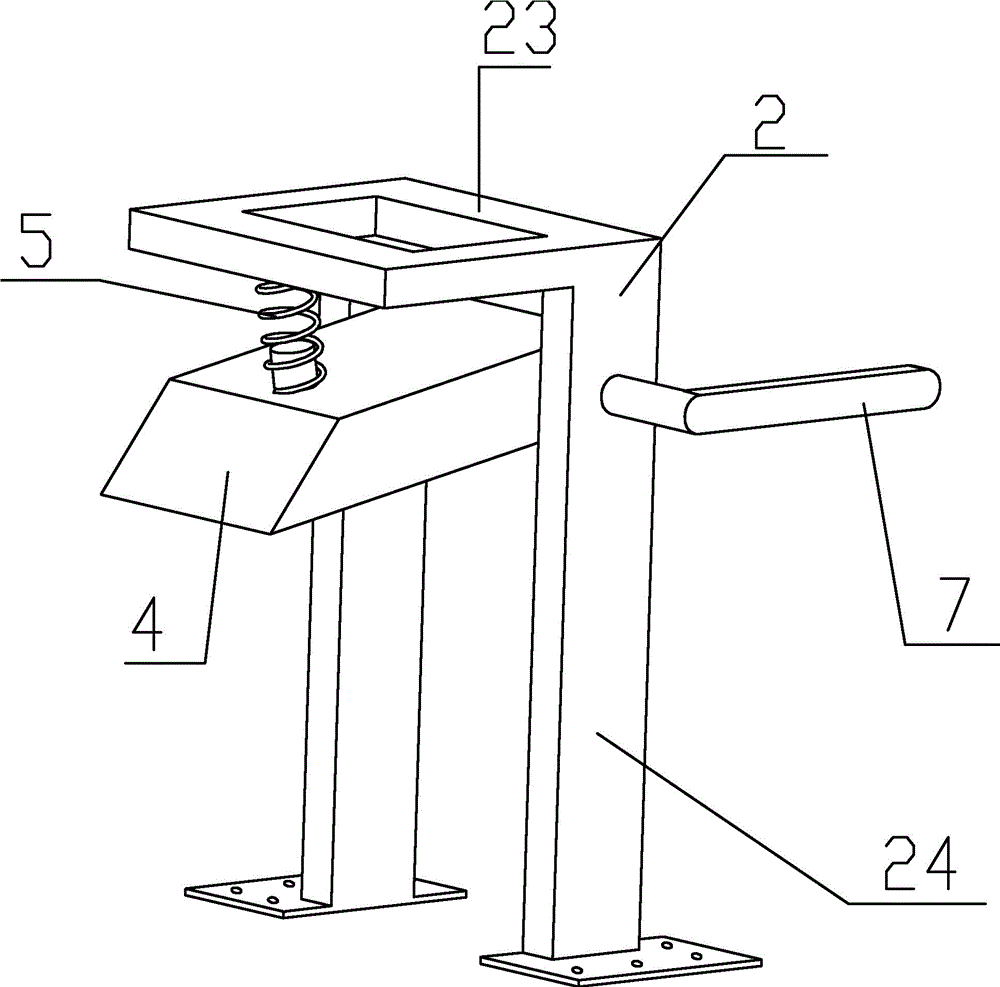

[0017] Such as Figure 4 and figure 2 Shown, first select channel steel to be welded into " mouth " font upper bracket 23 for use, then respectively weld a lower bracket 24 perpendicular to upper bracket 23 " mouth " font planes at the ends of its two sides, and stay away from lower bracket 24 The end of the upper bracket 23 is welded with the fixing seat 8, and the spatula bracket 2 formed by welding is placed on both sides of the tray bracket 1, and the lower bracket 24 is fixed on the ground through the fixing seat 8 and expansion screws, and in the process of fixing , adjust the height of the fixing seat 8 to ensure that the lower bracket 24 is perpendicular to the ground after installation; In the middle, a second protrusion 21 is welded perpendicular to the concrete tray, which is preferably a circular steel column, or a screw-fixed circular plastic protrusion;

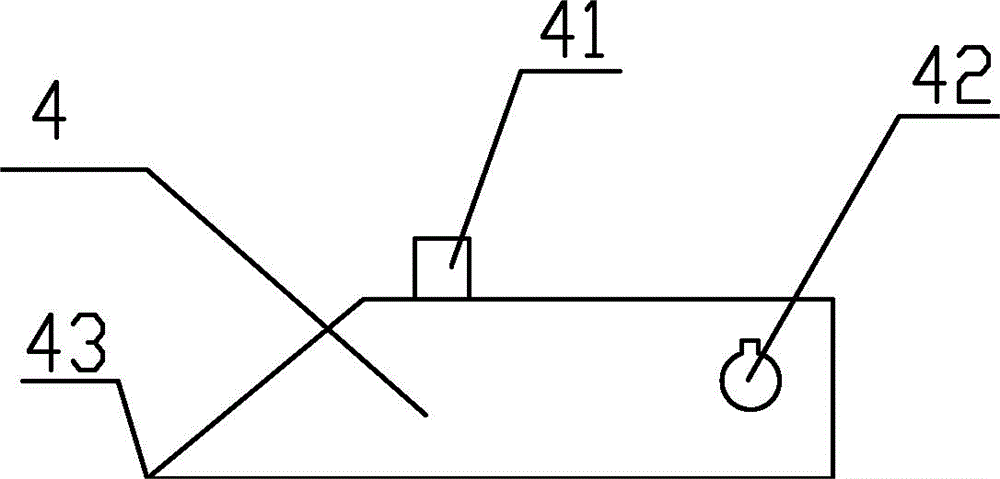

[0018] Such as figure 2 or Figure 5 Shown, when described axle selects a center to have flat key 44 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com