Cold and hot collinear cold-rolled color coating paint temperature automatic control device and its application method

A technology of temperature control device and heat exchange device, which is applied in the direction of surface coating liquid device, coating, etc., can solve the problems of excessive consumption of diluent, high toxicity, unfavorable surface quality control of color-coated products, etc., to reduce dilution The use of chemical agents and the obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

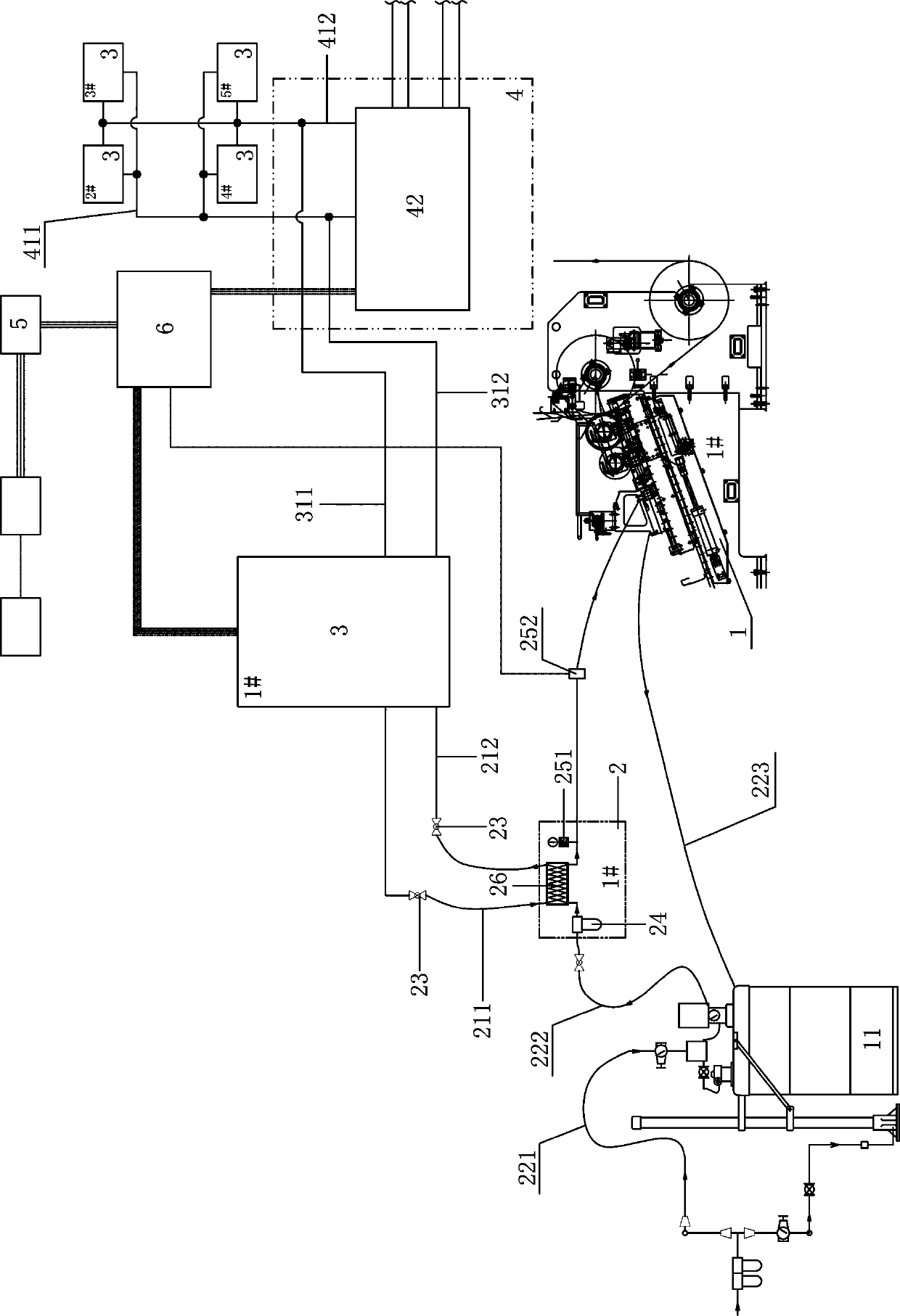

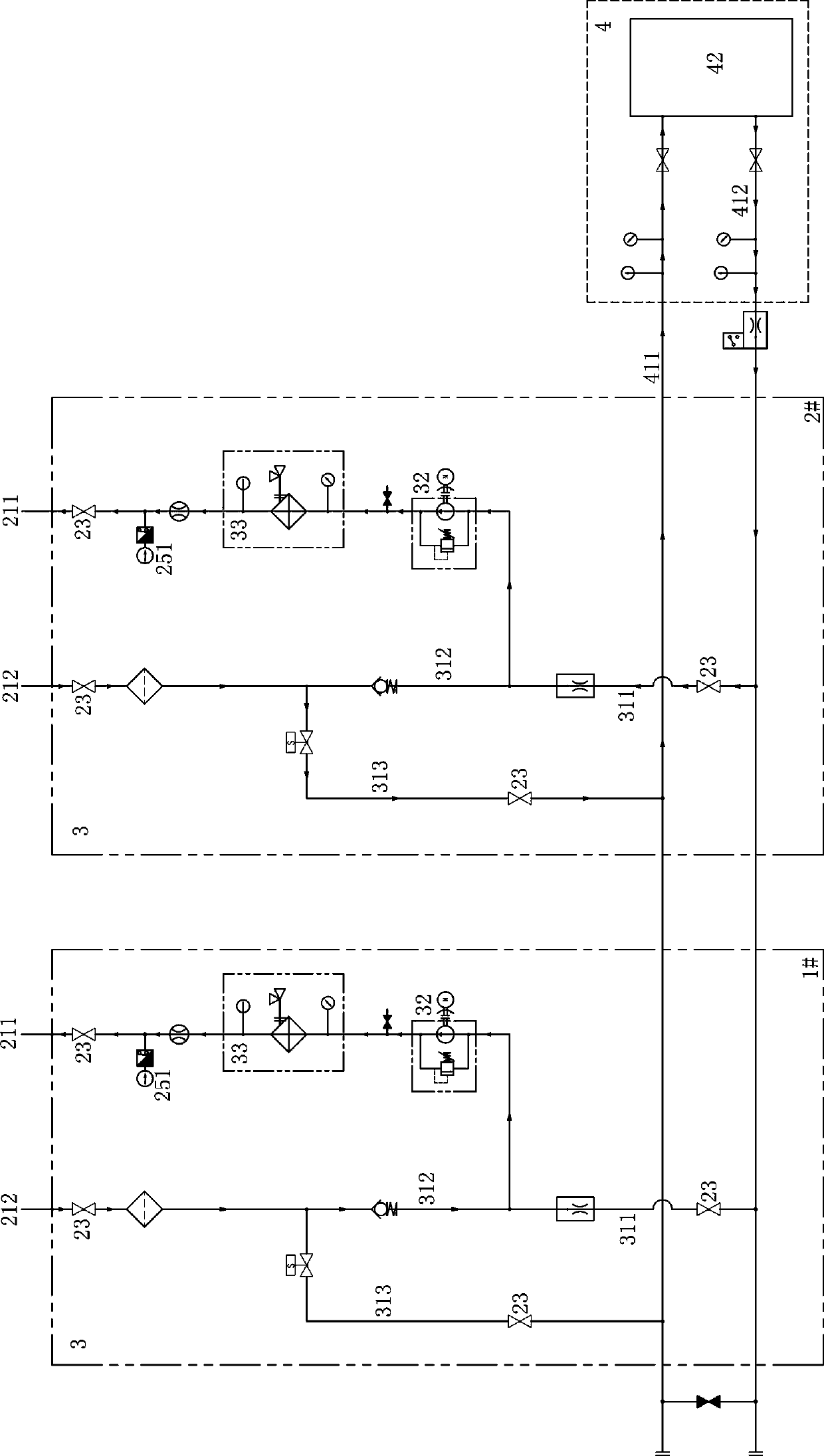

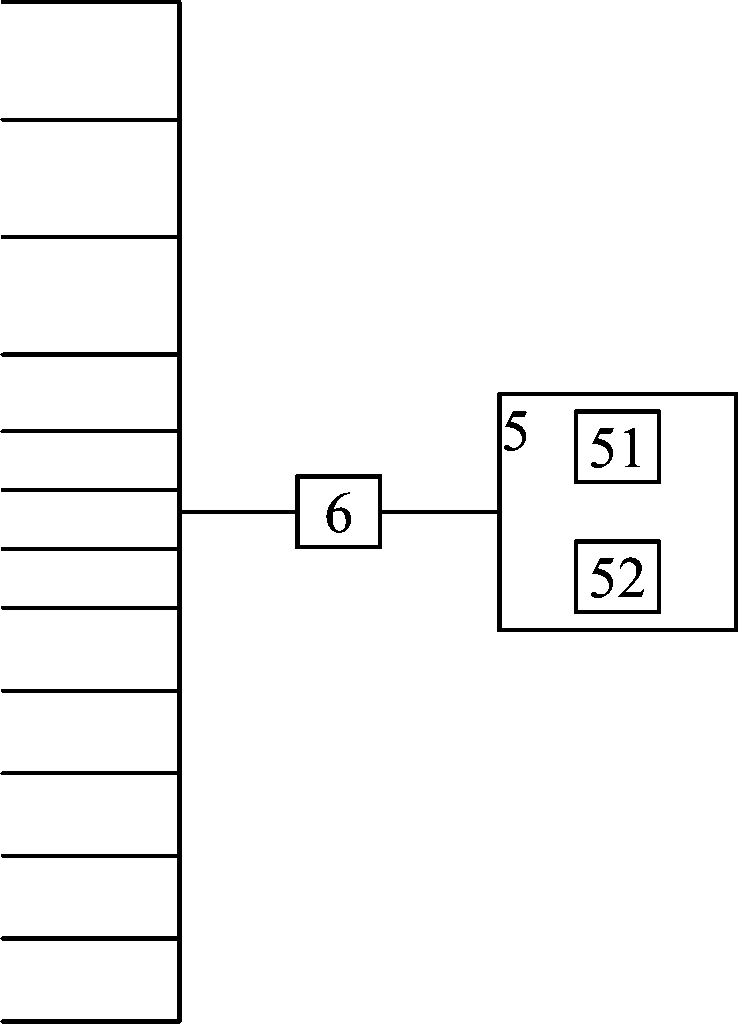

[0034] A cold-heating collinear cold-rolled color coating paint temperature automatic control device, including 5 coating machines 1, a heat exchange device 2, a paint temperature control device 3, a centralized refrigeration device 4, a control panel 5 and a controller 6, such as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0035]Let each coating machine 1 be numbered 1#, 2#, ... 5# respectively, and each coating machine 1 is provided with a paint container 11, and the paint container 11 is provided with a material return port and a material discharge port.

[0036] The number of heat exchange devices 2 is equal to the number of coating machines 1, and one side of each coating machine 1 is provided with a heat exchange device 2. The heat exchange device 2 includes a circulating water inlet pipe 211, a circulating water outlet pipe 212, a paint Inlet pipe 221, paint outlet pipe 222, paint return pipe 223, solenoid valve 23, filter 24, temperature sensor 251, vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com