Method for stabilizing gas adsorption and desorption temperature by utilizing phase-change energy storage material

A phase change energy storage material and gas adsorption technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of poor repeatability of adsorption operations, temperature rise, difficulty in regeneration of adsorbents, etc. Conducive to desorption and adsorbent regeneration, more efficient adsorption and desorption processes, and controllable adsorption and desorption processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

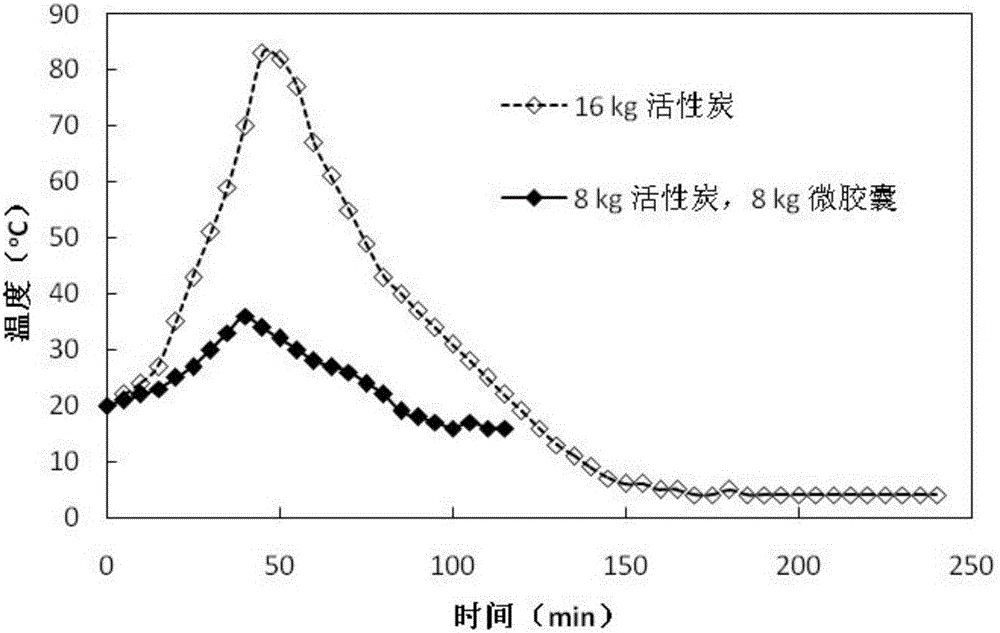

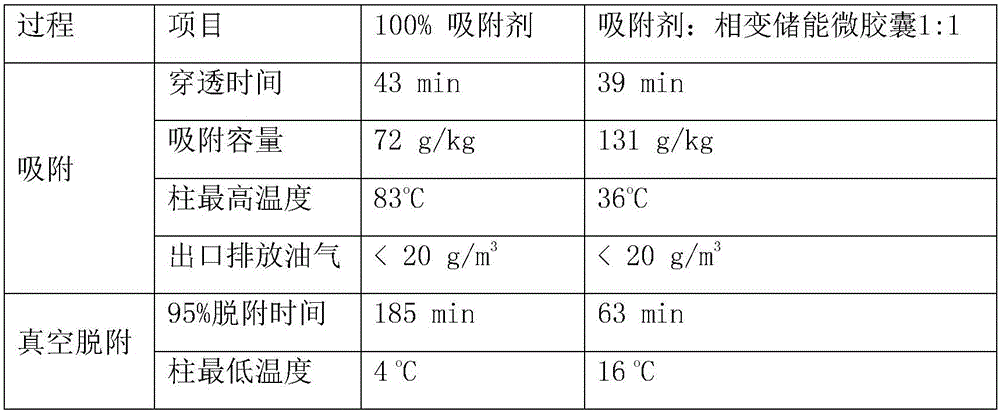

[0019] Example 1 A method for stabilizing gas adsorption and desorption temperature using phase change energy storage materials

[0020] Conditions: The diameter of the adsorption column is 300mm, and the column height is 700mm;

[0021] The oil and gas to be adsorbed is C 1 -C 5 mixed gasoline vapor;

[0022] Inlet gas-air mixture flow rate is 5m 3 / h, the temperature and pressure are 20°C and 101.3kPa respectively, and the inlet oil and gas mass concentration is 322g / m 3 .

[0023] During the experiment, activated carbon was used as the adsorbent, and the maximum adsorption capacity was 453g / kg; the adsorbent and phase-change energy storage microcapsules were mixed at a mass ratio of 1:1, that is, 8kg of activated carbon and 8kg of phase-change energy storage microcapsules were mixed evenly and then filled into the adsorption column. Among them, the phase change energy storage microcapsule has a core-shell structure with calcium sulfate as the shell and paraffin as the...

Embodiment 2-6

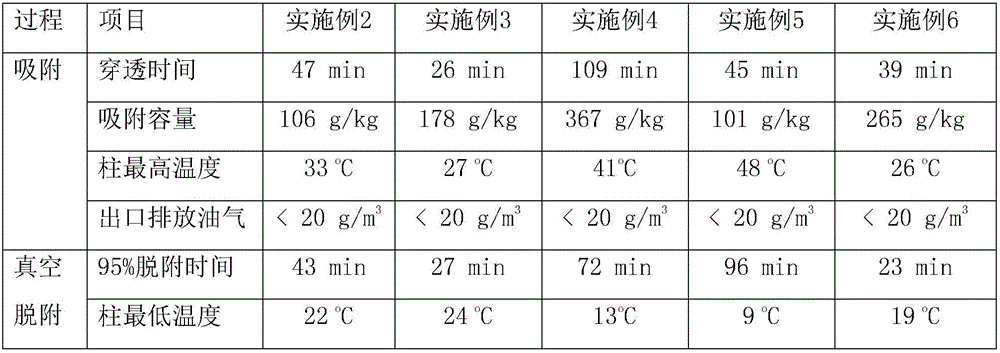

[0028] Example 2-6 A method for stabilizing gas adsorption and desorption temperature using phase change energy storage materials

Embodiment 2

[0029] Example 2, the conditions are the same as in Example 1, using silica gel as the adsorbent, the maximum adsorption capacity is 298g / kg; the adsorbent and phase-change energy storage microcapsules are mixed in a mass ratio of 3:1, that is, 12kg of silica gel and 4kg of phase-change energy storage The energy microcapsules are mixed evenly and then filled into the adsorption column. The phase change energy storage microcapsules have a core-shell structure with aluminum as the shell and tetrahydrate and potassium fluoride as the core, with a diameter of 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com