Dendrobium flower tea and processing method thereof

A processing method and technology of dendrobium, applied in the field of dendrobium scented tea and its processing, can solve the problems of destroying the enzyme activity in dendrobium flowers, less effective substances, and reducing active ingredients, and achieve the effects of increasing content, lasting aroma, and increasing water extracts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

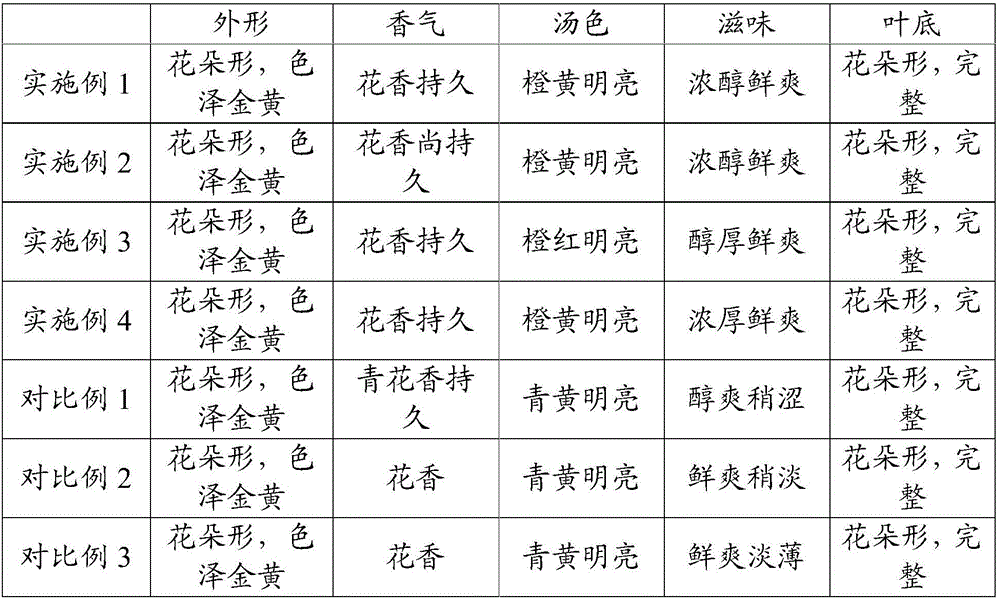

Examples

Embodiment 1

[0023] A processing method of dendrobium scented tea, comprising the following steps:

[0024] (1) gather the dendrobium flower;

[0025] (2) Withering the Dendrobium flowers at 28-32° C. for 12 hours until the water content is 60-62%, to obtain withered flowers;

[0026] (3) Knead the withered flowers: take the flowers to the upper edge of the flat kneading barrel as the standard, and the flowers should be flat and slightly pressed; empty kneading (even if the kneading cover is slightly attached to the withered flowers, without applying pressure) for 6 minutes, you can knead the flowers (above Empty is the conventional meaning in this field);

[0027] (4) ferment the kneading flowers for 3.5 hours, the fermentation temperature is 26-28° C., and the relative humidity is above 90%, to obtain fermented flowers;

[0028] (5) Microwave-dry the fermented flower with a 1000W microwave oven at 100°C until the water content is 30-35%, to obtain the first-baked flower;

[0029] (6) ...

Embodiment 2

[0031] A processing method of dendrobium scented tea, comprising the following steps:

[0032] (1) gather the dendrobium flower;

[0033] (2) Withering the Dendrobium flowers at 26-28° C. for 10 hours until the water content is 60-62%, to obtain withered flowers;

[0034] (3) Knead the withered flowers: take the flowers to the upper edge of the flat kneading barrel as the standard, and the flowers should be flat and slightly pressed; empty kneading (even if the cover is slightly attached to the withered flowers, without applying pressure) for 5 minutes, you can knead the flowers (above Empty is the conventional meaning in this field);

[0035] (4) ferment the kneading flowers for 3 hours, the fermentation temperature is 24-26° C., and the relative humidity is above 90%, to obtain fermented flowers;

[0036] (5) Microwave-dry the fermented flower with a 1000W microwave oven at 95°C until the water content is 30-35%, to obtain the first-baked flower;

[0037] (6) Pack the fir...

Embodiment 3

[0039] A processing method of dendrobium scented tea, comprising the following steps:

[0040] (1) gather the dendrobium flower;

[0041] (2) Withering the Dendrobium flowers at 27-32° C. for 14 hours until the water content is 60-62%, to obtain withered flowers;

[0042] (3) Knead the withered flowers: take the flowers to the upper edge of the flat kneading barrel as the standard, and the flowers should be flat and slightly pressed; empty kneading (even if the kneading cover is slightly attached to the withered flowers, without applying pressure) for 7 minutes, you can knead the flowers (above Empty is the conventional meaning in this field);

[0043] (4) ferment the kneading flowers for 4 hours, the fermentation temperature is 28-30° C., and the relative humidity is above 90%, to obtain fermented flowers;

[0044] (5) Microwave-dry the fermented flowers with a 1000W microwave oven at 105°C until the water content is 30-35%, to obtain the first-baked flowers;

[0045] (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com