Method for producing selenium-enriched rice through green manure-rice rotation

A technology for rice and green manure, applied in the fields of rice cultivation, botanical equipment and methods, potash fertilizer, etc., can solve the problems of increased selenium content in rice, food safety risks, large consumption of selenium fertilizer, etc. The utilization rate of selenium fertilizer and the effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

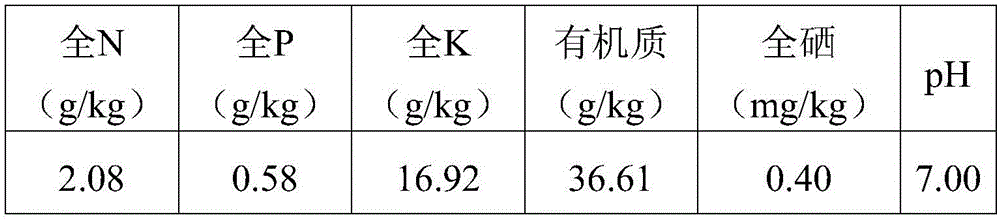

Embodiment 1

[0032] Preparation of organic selenium-enriched foliar fertilizer:

[0033] (1) Take the required raw materials of each component according to the ratio of parts by weight: 55 parts of alcohol waste liquid and 4.5 parts of sodium selenite, and then dissolve sodium selenite; wherein, the alcohol waste liquid is produced by molasses or cassava The waste liquid produced in the alcohol process is obtained by evaporation and concentration, and the hammer of the waste liquid is ≥50°Bx;

[0034] (2) Slowly add the sodium selenite dissolved in step (1) into the alcohol waste liquid, while adding the sodium selenite solution, shake well; after adding, place the resulting mixed solution on the shaker Shake for 180 minutes, the shaking frequency is 100r / min, and the temperature is 30°C; the obtained organic selenium-enriched foliar fertilizer is used for later use.

[0035] A method for producing selenium-enriched rice in green manure-rice rotation, comprising the following steps:

[0...

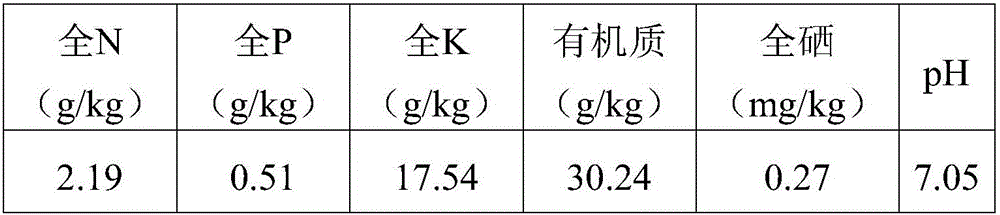

Embodiment 2

[0046] Preparation of organic selenium-enriched foliar fertilizer:

[0047] (1) Take the required raw materials of each component according to the ratio of parts by weight: 50 parts of alcohol waste liquid and 4.5 parts of sodium selenite, and then dissolve sodium selenite; wherein, the alcohol waste liquid is produced by molasses or cassava The waste liquid produced in the alcohol process is obtained by evaporation and concentration, and the hammer of the waste liquid is ≥50°Bx;

[0048] (2) Slowly add the sodium selenite dissolved in step (1) into the alcohol waste liquid, while adding the sodium selenite solution, shake well; after adding, place the resulting mixed solution on the shaker Shake for 180 minutes, the shaking frequency is 100r / min, and the temperature is 30°C; the obtained organic selenium-enriched foliar fertilizer is used for later use.

[0049] A method for producing selenium-enriched rice in green manure-rice rotation, comprising the following steps:

[0...

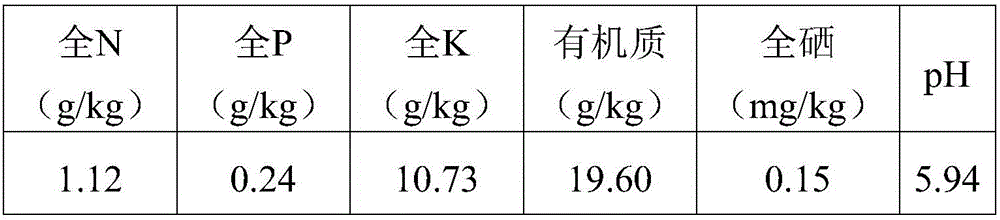

Embodiment 3

[0060] Preparation of organic selenium-enriched foliar fertilizer:

[0061] (1) Take the required raw materials of each component according to the ratio of parts by weight: 60 parts of alcohol waste liquid and 4.5 parts of sodium selenite, and then dissolve sodium selenite; wherein, the alcohol waste liquid is produced by molasses or cassava The waste liquid produced in the alcohol process is obtained by evaporation and concentration, and the hammer of the waste liquid is ≥50°Bx;

[0062] (2) Slowly add the sodium selenite dissolved in step (1) into the alcohol waste liquid, while adding the sodium selenite solution, shake well; after adding, place the resulting mixed solution on the shaker Shake for 180 minutes, the shaking frequency is 100r / min, and the temperature is 30°C; the obtained organic selenium-enriched foliar fertilizer is used for later use.

[0063] A method for producing selenium-enriched rice in green manure-rice rotation, comprising the following steps:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com