Air-aspiration type precise seeder

A precision seeding, air suction technology, applied in the field of agricultural machinery, can solve the problems of high porosity, unable to achieve accurate seeding, and the air suction cavity is not tightly closed, and achieve the effect of accurate position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

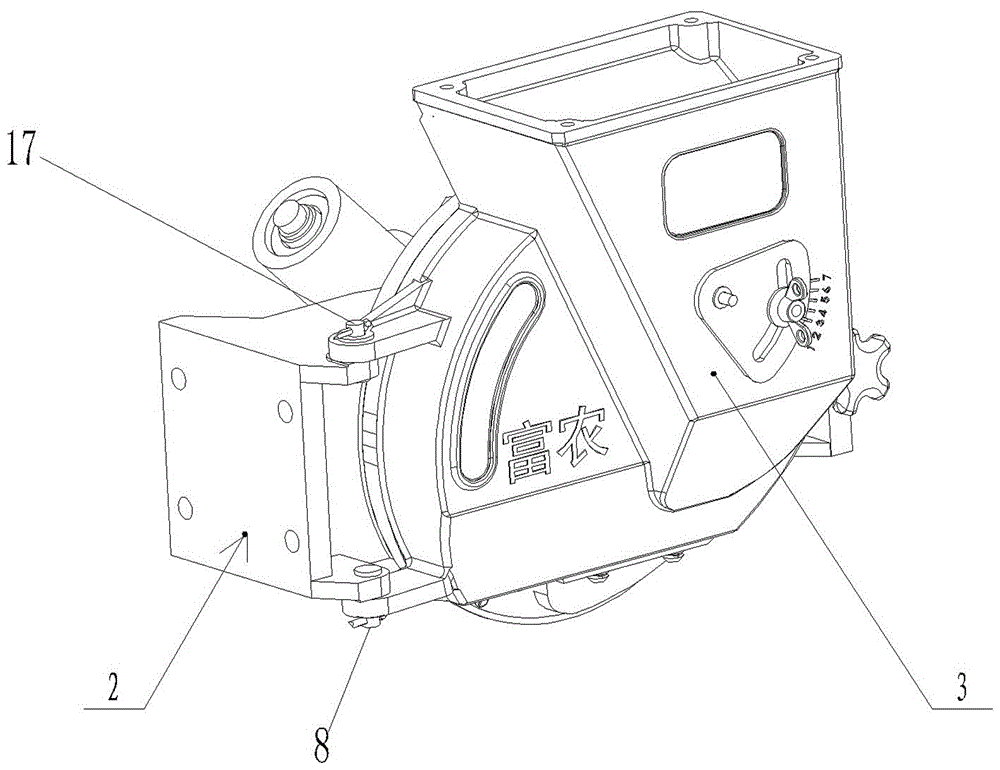

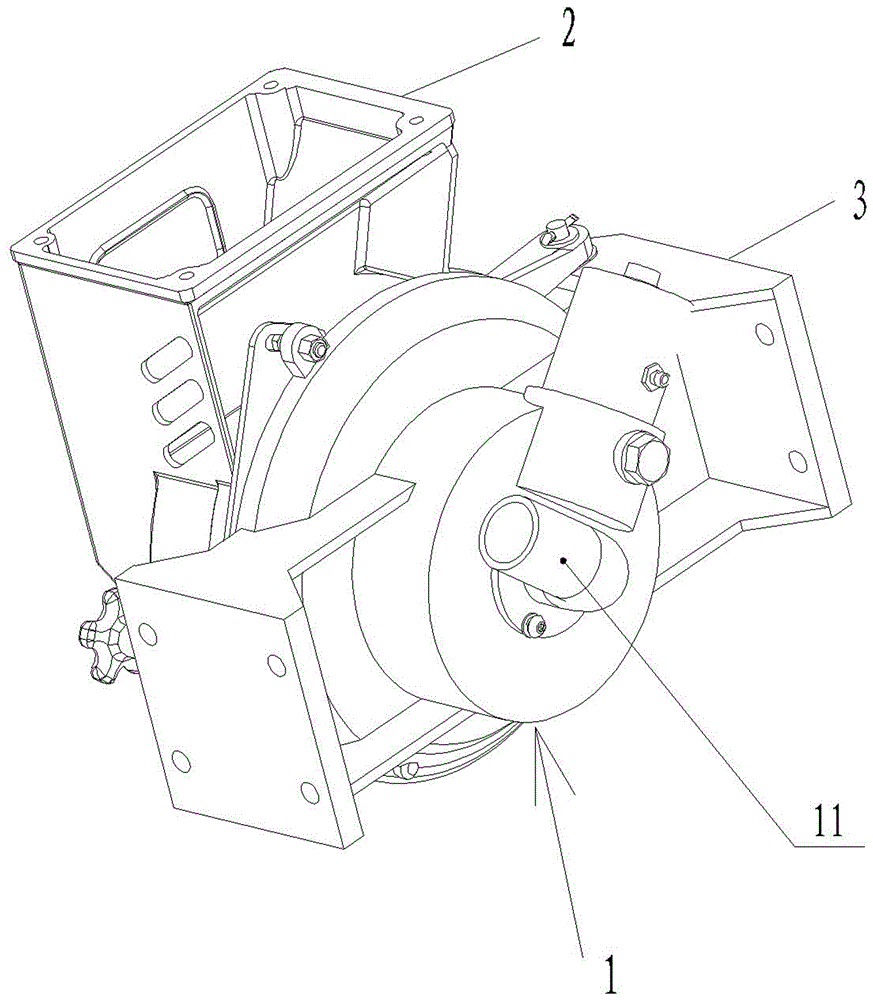

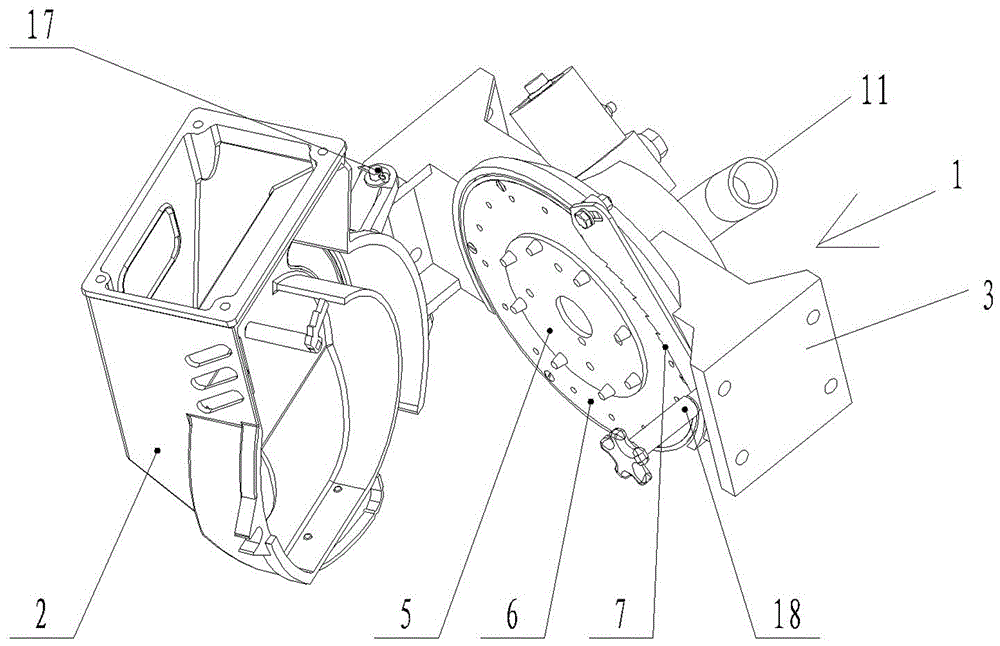

[0026] A kind of air-suction precision seeder, comprises seeding mechanism 1, seed chamber assembly 2, is characterized in that:

[0027] The sowing mechanism 1 includes a sowing mechanism support body 10, a stirring wheel 5, a sowing disc 6, a sawtooth seed scraper 7, a screw 11, an air cut-off baffle 12, a gland 13, an air suction chamber 14, a first bevel gear 15, a second Bevel gear 22, bearing one 16, bearing two 21, transmission shaft 20, elbow 3. The stirring wheel 5 is fixed on the sowing disc 6 . The sowing disc 6 is mounted on the suction chamber 14 by means of set screws 11 . The suction chamber 14 is mounted on the first bevel gear 15 . The first bevel gear 15 meshes with the second bevel gear 22 in the gear chamber of the sowing mechanism support body 10, and is connected with the sowing mechanism support body 10 through bearing one 16 and bearing two 21 respectively. The second bevel gear 22 is connected with the transmission shaft 20, and the first bevel gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com