A realization method of space propulsion system

A technology of propulsion system and propellant, which is applied in the direction of aerospace vehicle propulsion system devices, jet propulsion devices, rocket engine devices, etc. It can solve the problems of not being able to adapt to filling and achieve the effect of fault isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] The specific functions and implementation plans are as follows:

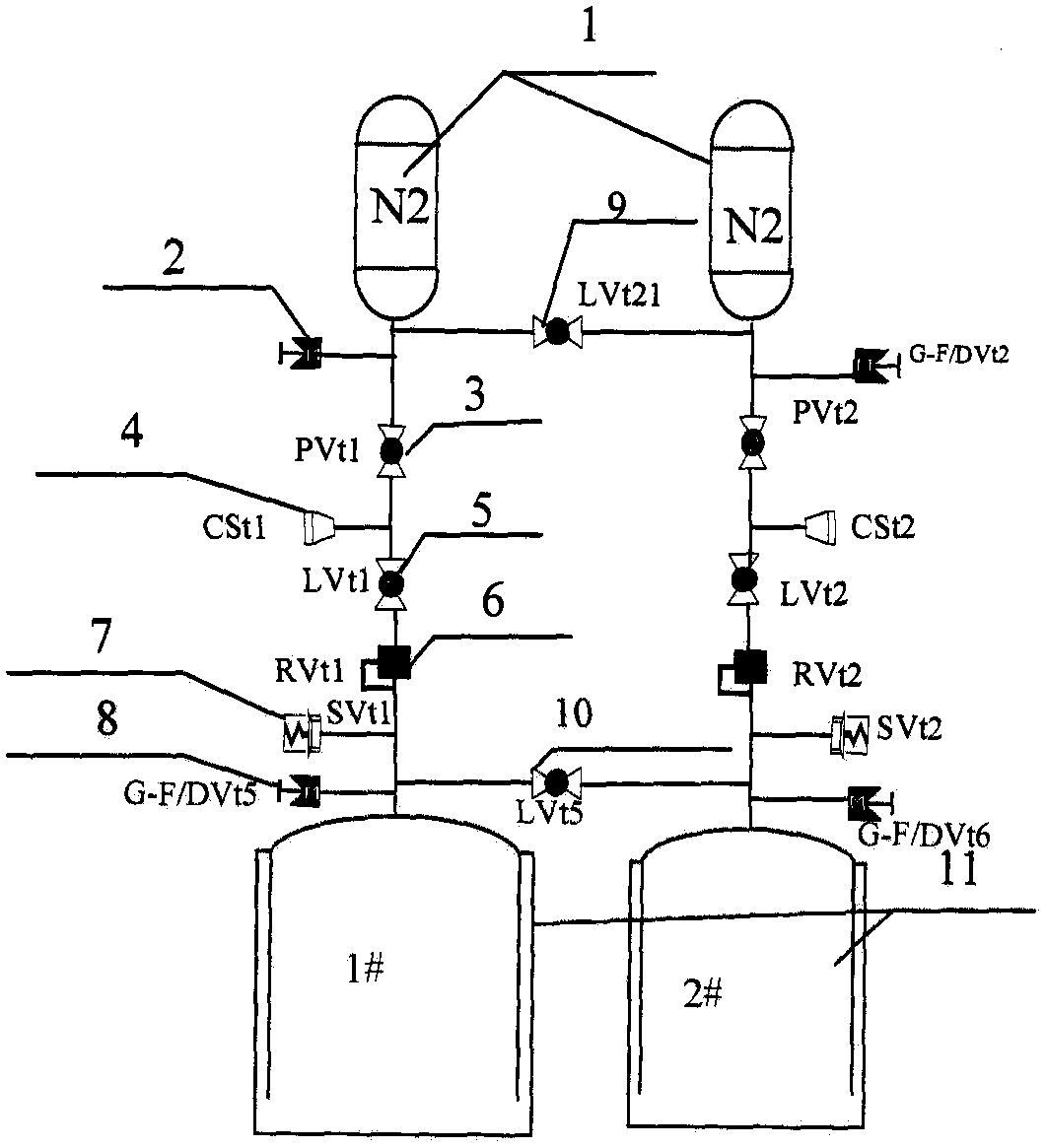

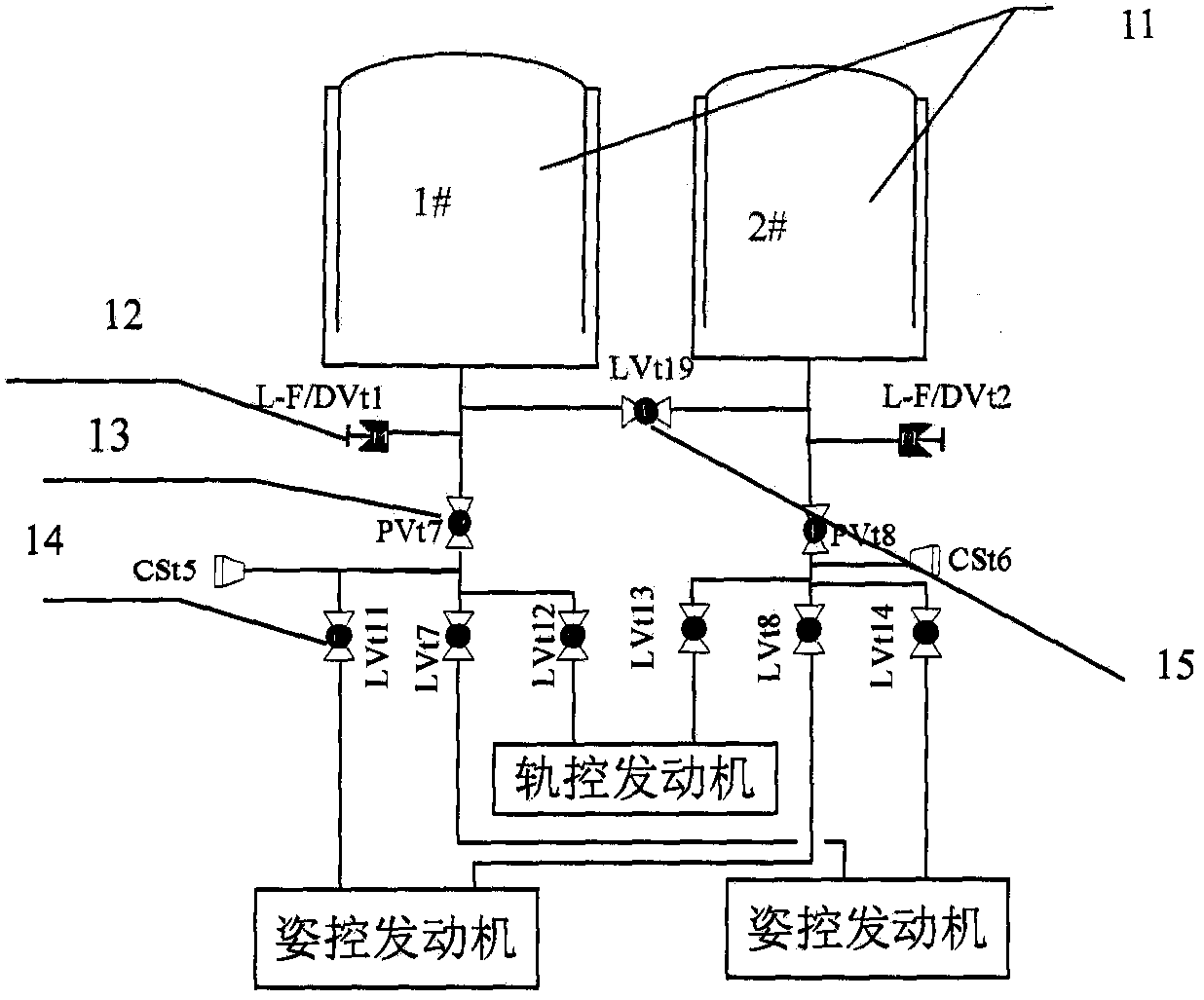

[0046] like figure 1 Shown: 1 is the gas cylinder, 2 is the filling valve, 3 is the electric explosion valve, 4 is the test port, 5 is the high pressure self-locking valve, 6 is the pressure reducing valve, 7 is the safety valve, 8 is the filling valve, 9 10 is a two-way high-pressure self-locking valve, 10 is a low-pressure self-locking valve, and 11 is a storage tank.

[0047] That is, each storage tank 11 has a gas cylinder 1 to supply extruding gas for it under the normal mode. During in-orbit operation, the electric explosion valve 3 and the high-pressure self-locking valve 5 downstream of the gas cylinder 1 are sequentially opened. After the high-pressure gas is reduced to the rated working pressure through the pressure-reducing valve 6, it enters the air chamber of the storage tank 11, and the gas circuit is completed. supercharged.

[0048] The inventive point of the present invention is that: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com