Permanent magnet speed regulation automobile driving electric motor

A technology for driving motors and permanent magnet speed regulation, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electric components, etc., can solve the problem of single design of rotor stamping magnetic steel slots and magnetic isolation bridges, short circuit of excitation magnetic flux, and reduction of mechanical Performance and other issues, to achieve excellent electromagnetic performance, reduce starting current, and avoid magnetic short circuit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

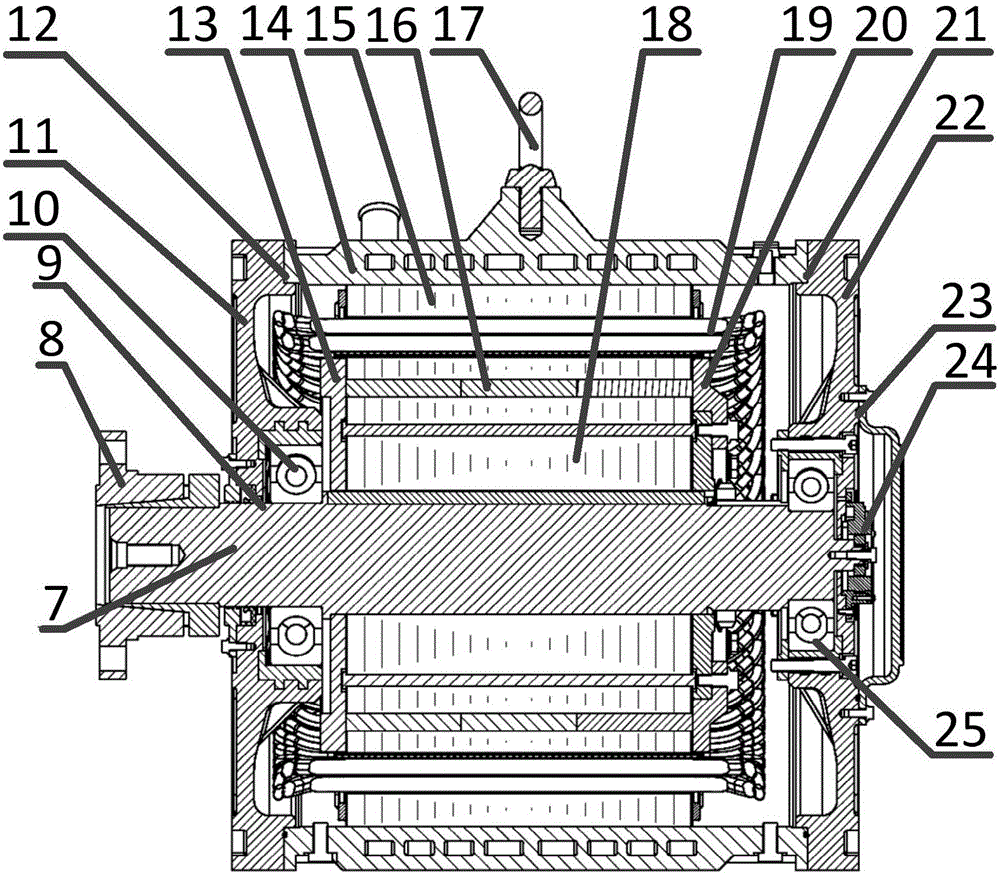

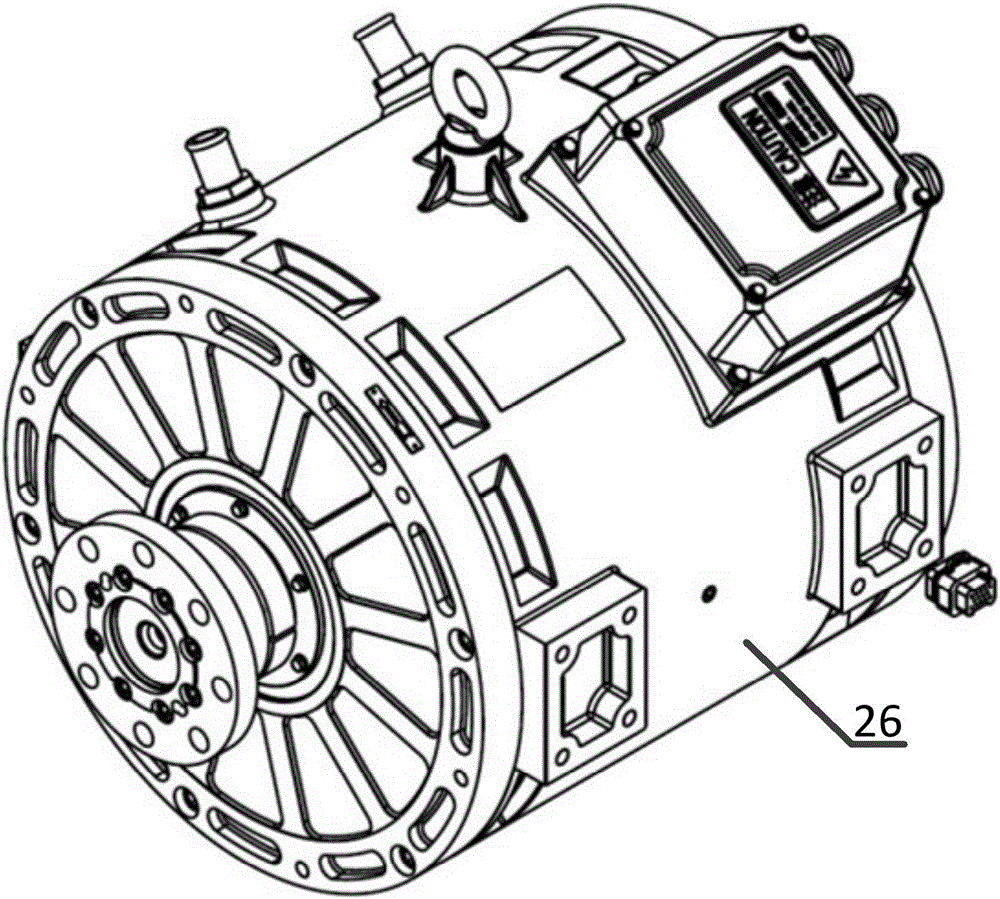

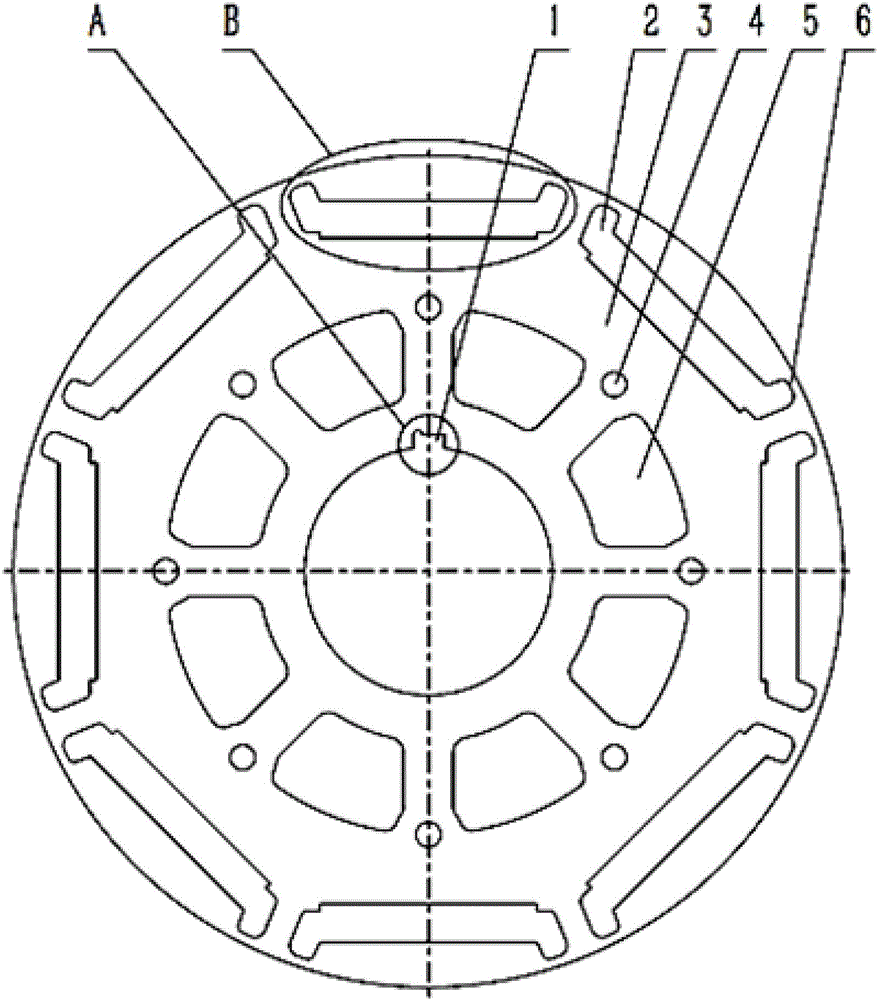

[0050] Such as figure 1 with figure 2 As shown, the present invention proposes a permanent-magnet speed-regulating automobile drive motor, wherein the permanent-magnet speed-regulating automobile drive motor is sequentially provided with a shaft 7, a rotor core 18, a rotor magnet 16, and a coil 19 from the inner layer to the outer layer. , The stator core 15 and the casing 26, where, such as image 3 with Figure 5 As shown, the rotor core 18 is a plurality of mutually overlapping rotor punching pieces 28. The rotor punching piece 28 includes a rotor punching piece body 3 and a magnetic steel slot 2 arranged on the rotor punching piece body 3; the magnetic steel slots 2 include mutually communicating The central groove 202, the magnetic steel stop groove 203, the first extension wing groove 201 and the second extension wing groove 204, and the magnetic steel stop groove 203, the first extension wing groove 201 and the second extension wing groove 204 surround the center The gro...

no. 2 example

[0089] The second embodiment of the present invention will be described below.

[0090] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment is that in the second embodiment, twelve magnetic steel grooves 2 are uniformly opened on the rotor punch body 3, and the first magnetic steel groove 2 on both sides of each magnetic steel groove 2 A plurality of magnetic isolation bridges 6 are formed between the upper edges of the extended wing groove 201 and the second extended wing groove 204 and the outer edge of the rotor punch body 3, and a plurality of positioning protrusions 29 are provided on the inner side of the rotor punch body 3. And positioning groove 30. In addition, the second embodiment can adopt other features of the first embodiment. Therefore, for the sake of brevity, only the differences of the second embodiment are described below.

[0091] In this embodiment, the ventilation holes 5 can be arranged corresponding to the magnetic st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com