Non-contact trigger type net-liked electronic drum

A trigger type, electronic drum technology, applied in the direction of electroacoustic musical instruments, percussion instruments, instruments, etc., can solve the problems of bad audio signal, weakened mechanical signal, poor mesh surface contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

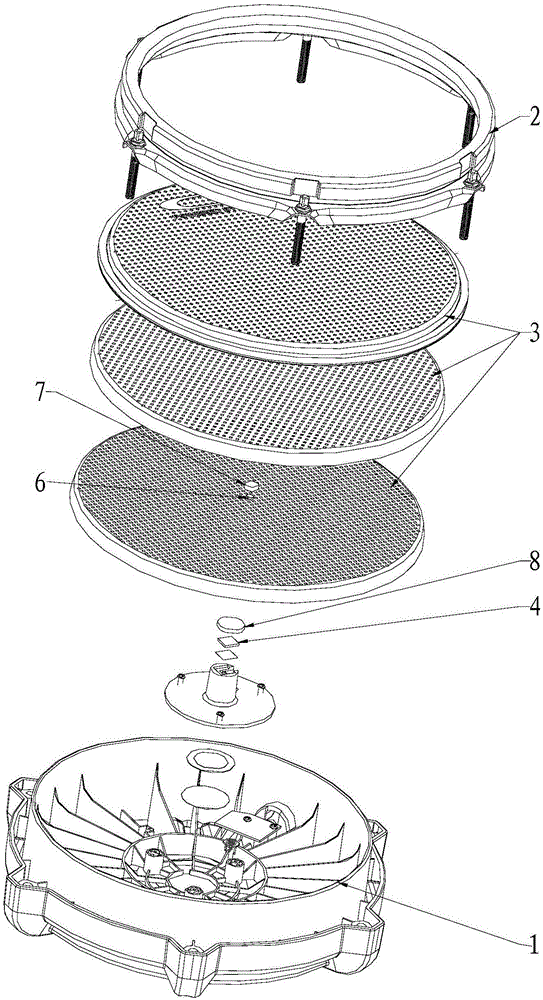

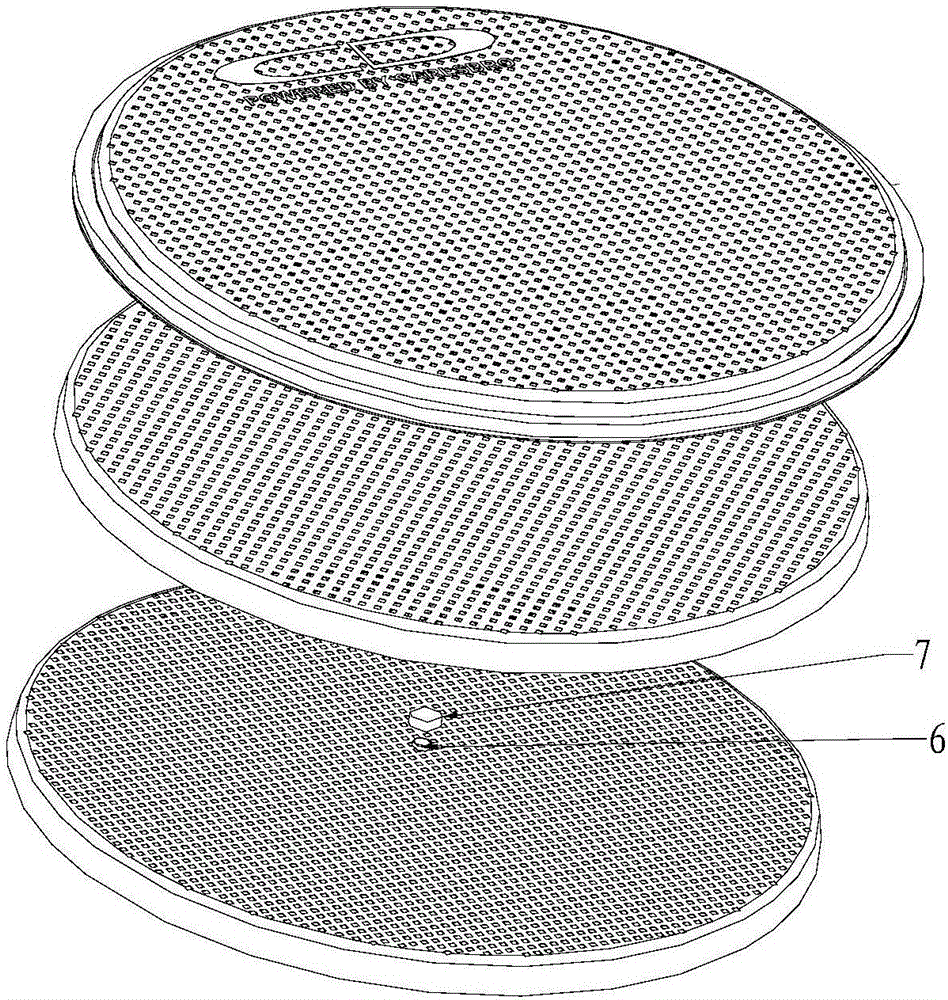

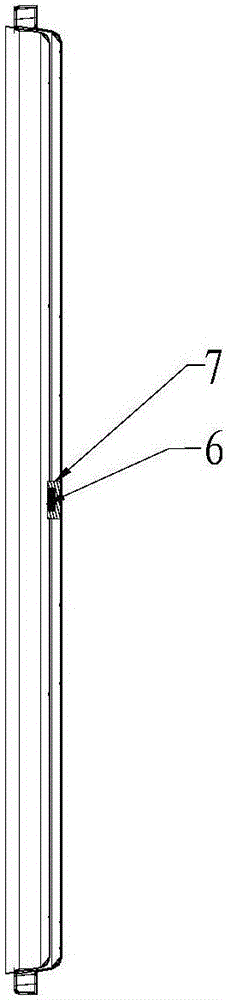

[0025] Embodiment one: if Figure 1-Figure 4As shown, a non-contact trigger type mesh electronic drum includes a drum disc 1, a drum head, a data acquisition module and a data processing module. The drum head includes a drum ring 2 and a drum surface 3, and the drum ring 2 fixes the drum surface 3 On the drum disc 1, the data acquisition module includes a trigger and a conductive medium, the drum surface 3 is formed by laminating three layers of mesh, and the trigger includes a PCB board 4 and a Hall effect sensor chip 5 installed on the lower surface of the PCB board 4 , the conductive medium is a magnetic component, the magnetic component is arranged between the first layer of mesh surface and the second layer of mesh surface, the magnetic component is clamped by the first layer of mesh surface and the second layer of mesh surface, and the magnetic component is located at the center of the drum surface 3 , the PCB board 4 is installed in the drum 1, the PCB board 4 is locate...

Embodiment 2

[0028] Embodiment two: if Figure 1-Figure 4 As shown, a non-contact trigger type mesh electronic drum includes a drum disc 1, a drum head, a data acquisition module and a data processing module. The drum head includes a drum ring 2 and a drum surface 3, and the drum ring 2 fixes the drum surface 3 On the drum disc 1, the data acquisition module includes a trigger and a conductive medium, the drum surface 3 is formed by laminating three layers of mesh, and the trigger includes a PCB board 4 and a Hall effect sensor chip 5 installed on the lower surface of the PCB board 4 , the conductive medium is a magnetic component, the magnetic component is arranged between the second layer of mesh surface and the third layer of mesh surface, the magnetic component is clamped by the second layer of mesh surface and the third layer of mesh surface, and the magnetic component is located at the center of the drum surface 3 , the PCB board 4 is installed in the drum 1, the PCB board 4 is locat...

Embodiment 3

[0031] Embodiment three: as Figure 1-Figure 4 As shown, a non-contact trigger type mesh electronic drum includes a drum disc 1, a drum head, a data acquisition module and a data processing module. The drum head includes a drum ring 2 and a drum surface 3, and the drum ring 2 fixes the drum surface 3 On the drum disc 1, the data acquisition module includes a trigger and a conductive medium, the drum surface 3 is formed by laminating three layers of mesh, and the trigger includes a PCB board 4 and a Hall effect sensor chip 5 installed on the lower surface of the PCB board 4 , the conductive medium is a magnetic component, the magnetic component is arranged between the second layer of mesh surface and the third layer of mesh surface, the magnetic component is clamped by the second layer of mesh surface and the third layer of mesh surface, and the magnetic component is located at the center of the drum surface 3 , the PCB board 4 is installed in the drum 1, the PCB board 4 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com