A remote visual monitoring method for unmanned mining face

A technology for excavating working face and working face, applied in data processing applications, instruments, forecasting and other directions, can solve the problem of inability to accurately judge the operation status of production equipment, inability to obtain internal information of mining equipment in coal and rock mass and goaf, and inability to comprehensively and accurately judging the early warning situation of underground disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0045] A remote visual monitoring method for unmanned mining face (such as figure 1 shown), follow the steps below:

[0046] Step 1: Develop a real-time data exchange platform

[0047] Build a real-time data exchange platform to realize reliable and real-time exchange of video surveillance data, mine monitoring data, equipment monitoring data and application program data.

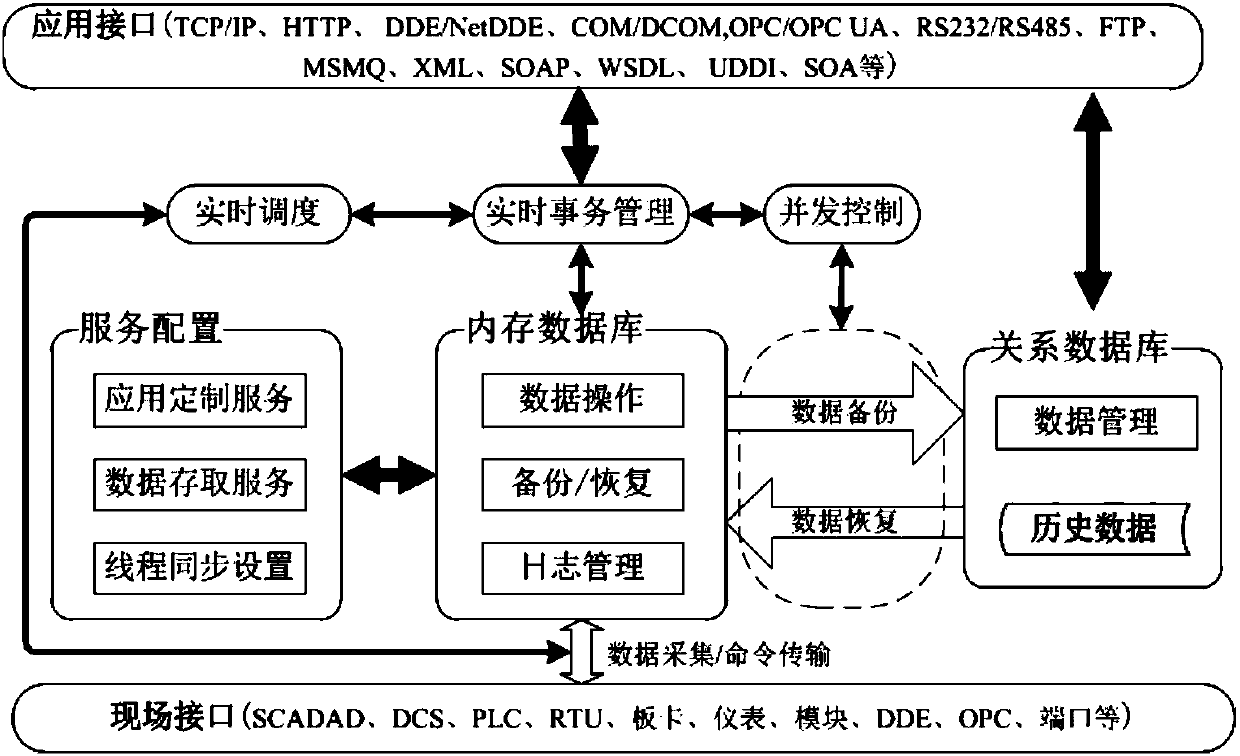

[0048] The architecture of the real-time data exchange platform is as follows: figure 2 shown. Since real-time data exchange involves a variety of data, the real-time data exchange platform must support multiple protocols and interfaces, be able to automatically process, store, and forward real-time data, and support custom data protocols to meet customization needs.

[0049] Step 2: Establish 3D model of working face and equipment model

[0050] Establish roof fracture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com