Acetylene production process operation displacement and charging control method

A technology of production process and control method, applied in the parts of acetylene gas generator, acetylene generator, comprehensive factory control, etc., can solve problems such as chaotic execution, potential safety hazards of replacement time, non-execution of procedures, etc., to overcome product quality influence, optimize product quality, and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

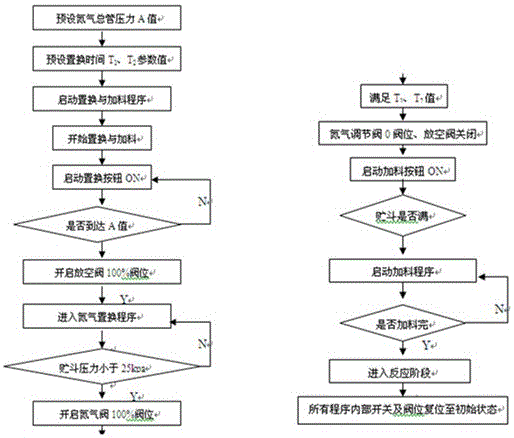

[0018] The difference between embodiment 2 and embodiment 1 is: the preset nitrogen replacement time value T 1 is 6 minutes, if the nitrogen main pipe pressure is less than the preset A value, then T 1 +2 minutes. That is, 8 minutes of nitrogen filling is the basis for judgment.

Embodiment 3

[0019] Embodiment 3 differs from Embodiment 1 in that: the control station newly adds a time relay device, and the preset time relay value T 2 is 6 minutes, if the nitrogen main pipe pressure is less than the preset A value, then T 2 +2 minutes. That is, 8 minutes of nitrogen filling is the basis for judging, and T 1 with T 2 The time condition must be satisfied at the same time.

Embodiment 4

[0020] The difference between embodiment 4 and embodiment 1 is that the DCS controls the internal switching value, and the internal switch and valve position start and reset program is newly added. Its function is to reset all internal switches and valve positions to initial state.

[0021] The preset pressure, temperature, and replacement time reference values in the above embodiments can be multiple based on experience, and the specific values are very important to the size and reaction characteristics of the acetylene generator, hopper, and storage hopper.

[0022] In the above embodiment, the preset nitrogen replacement time T 1 = T 2 .

[0023] The present invention mainly adds a time relay to the control station in the replacement and feeding stage, adds a DCS control replacement time setting and judgment program, and improves the program by adding an internal switch and a valve position start and reset program. Others are the same as the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com