Reliability test device and test method for voltage margin

A technology of voltage margin and test device, applied in printed circuit test, electronic circuit test, measurement using digital measurement technology, etc., can solve the problems of low test efficiency and high cost, improve test efficiency, reduce test cost and facilitate The effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

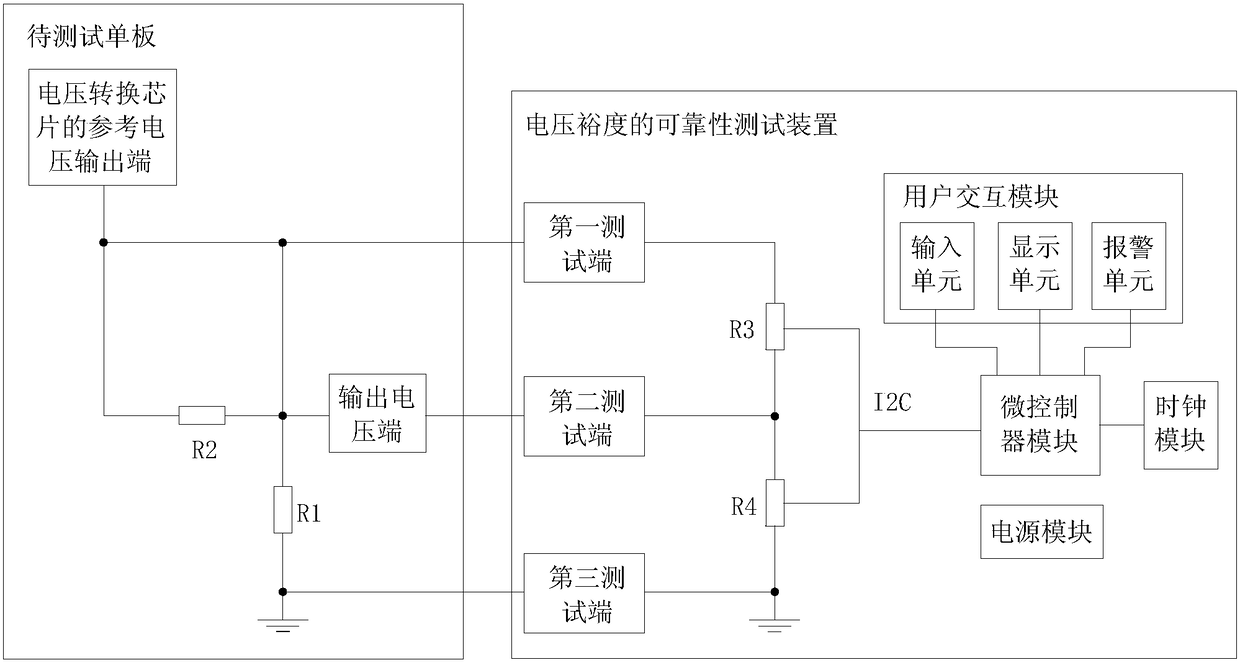

[0040] The system block diagram of the reliability testing device for voltage margin in the embodiment of the present invention during testing can be found in figure 2 , wherein, R1 is the first resistor, R2 is the second resistor, R3 is the first I2C adjustable resistor, and R4 is the second I2C adjustable resistor. It can be seen that the reliability test device for voltage margin in this example includes a first test terminal, a second test terminal, a third test terminal, a first I2C adjustable resistor R3, a second I2C adjustable resistor R4, a micro-controller module, clock module, user interaction module, power module and device ground wire, the first test terminal is connected to the second test terminal through the first I2C adjustable resistor R3, and the second test terminal is connected to the second I2C adjustable resistor R4 connected to the third test terminal, the third test terminal is connected to the ground wire of the device, the clock module and the user ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com