TBM excavation section anchor rod anti-drawing detection experiment device and using method

A test device and anti-pull technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of not being able to use the TBM equipment platform, increase the difficulty of bolt detection, and not carry out in time, so as to reduce the time-consuming detection test , Easy to promote and use, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

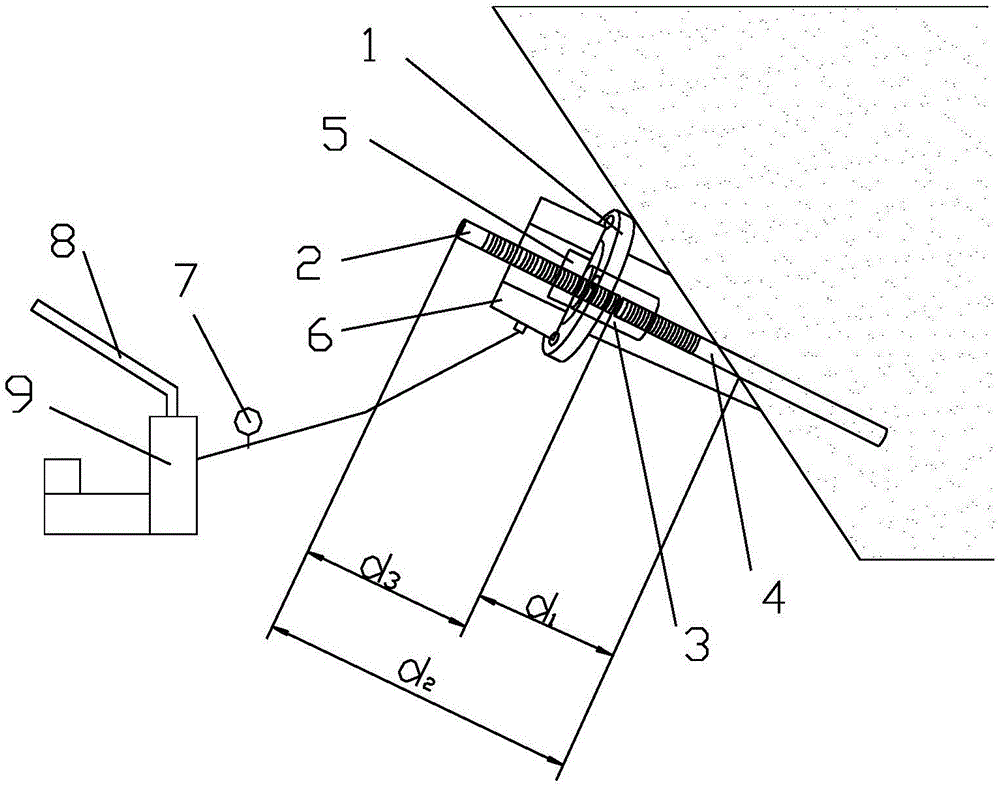

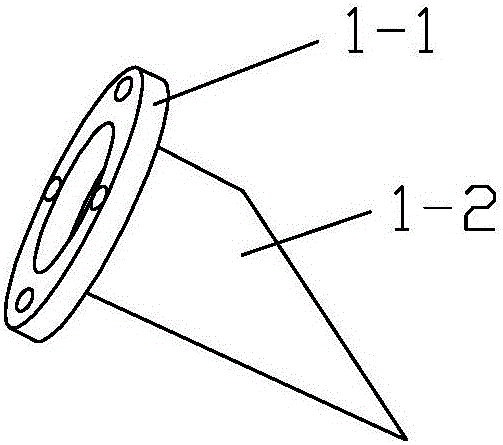

[0031] Such as figure 1 with figure 2 As shown, the present invention includes a bolt extension mechanism, a pressure member 1 and a pulling force loading mechanism. The connecting piece 3 of the rod 2 and the anchor rod 4, the pressure bearing 1 includes a pressure bearing plate 1-1 and a support pipe 1-2 through which the connecting piece 3 can pass, and the pressure bearing plate 1-1 is provided with The through hole for the connector 3 to pass through, the pressure bearing plate 1-1 is fixedly connected with the support pipe 1-2, the cross section of the support pipe 1-2 is an inclined surface, and the inclination angle of the inclined surface is related to the inclination The inclination angle of the rock face matches.

[0032] Such as figure 1 As shown, in this embodiment, the pulling force loading mechanism includes a hollow jack 6, a hydraulic pump 9 connected to the hollow jack 6, and an anchor joint 5 for connecting the anchor extension rod 2, on the hydraulic pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com