Spiral feeding-two-stage delivery type automatic sulfur measuring device for barium sulfate

A technology of screw feeding and screw feeder is applied in the field of automatic measuring equipment for sulfur content in barium sulfate, which can solve the difficulty in testing barium sulfate sulfur content, low efficiency, insufficient consideration of details, and high labor intensity of workers, etc. problems, to achieve excellent reliability and efficiency, simple structure and working principle, and low level of personnel participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

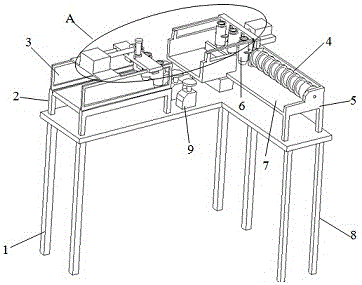

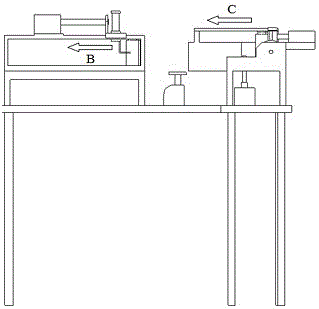

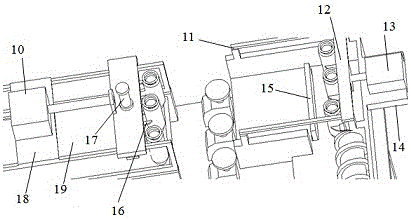

[0018] Compare below Figure 1 to Figure 3 To illustrate, the device has relatively high requirements on the motion sequence. Before the device works, the motion of each component should be checked, especially when the screw feeder 4 transports four weighing bottles 6 to the front of the baffle 15. The baffle plate 15 should be able to move down in time, and the bottle pushing cylinder 13 drives the pushing claw 2 12 to place the weighing bottle 6 on the electronic analytical balance 9, and the bottle fetching cylinder 10 can drive the pushing claw 1 16 to remove the weighing bottle in time. 6 is placed on the conveyor belt 19, thereby completing the transfer process of weighing bottle 6, secondly should ensure that each parts are connected reliably, avoid the safety accident that parts fall and injure people, so far the device completes the preparatory work.

[0019] When the device is working, after making the Ehrlich sample, it is placed on the combustion furnace 21 for cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com