Powerful soil-breaking reamer for dredger

A technology for dredgers and reamers, which is applied in the field of powerful soil-breaking reamers for dredgers, can solve the problems of reducing the service life of equipment, reducing the thickness of mud layers, and poor equipment, so as to reduce the overall size, improve soil-breaking ability, Improve the effect of the channeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

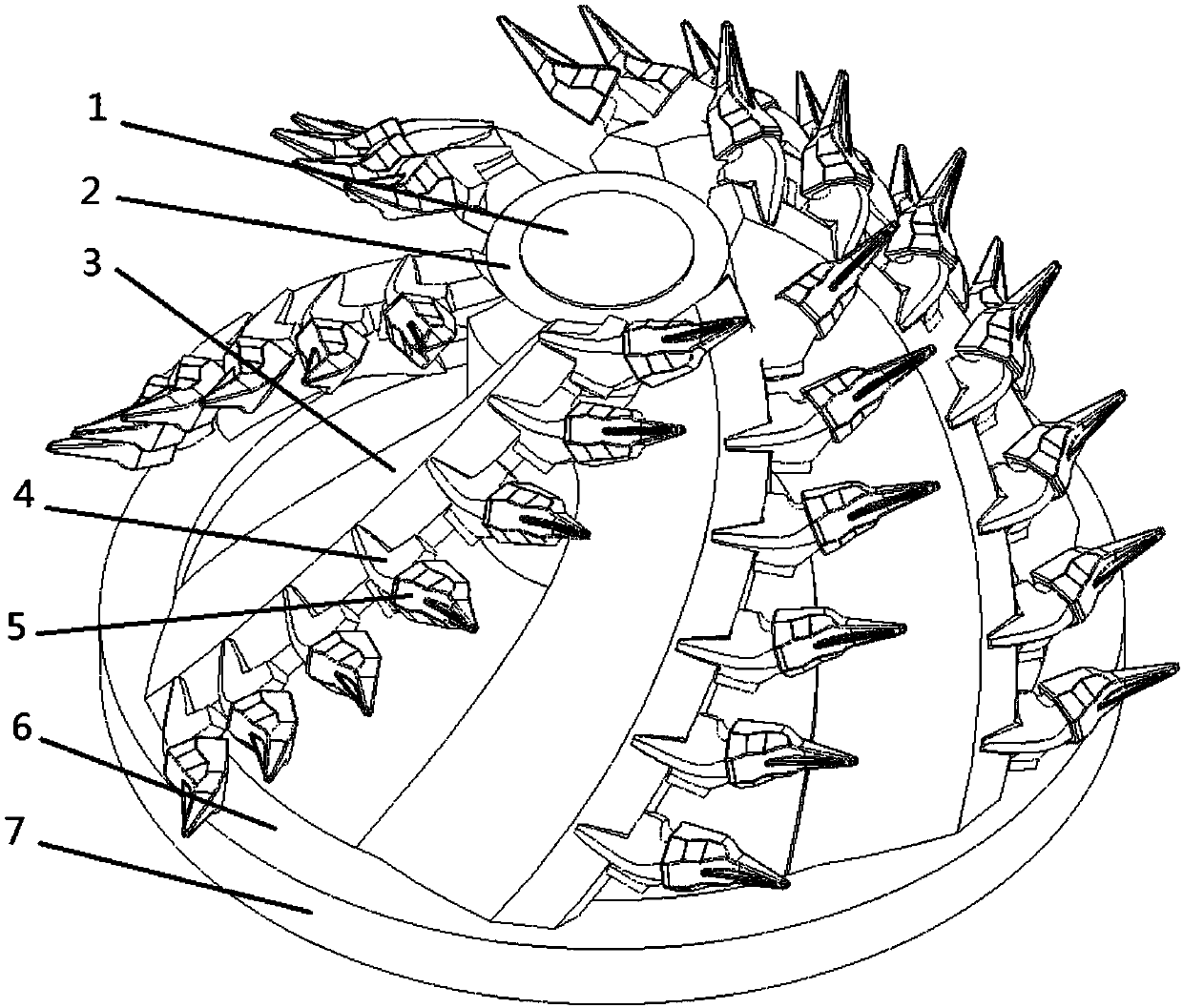

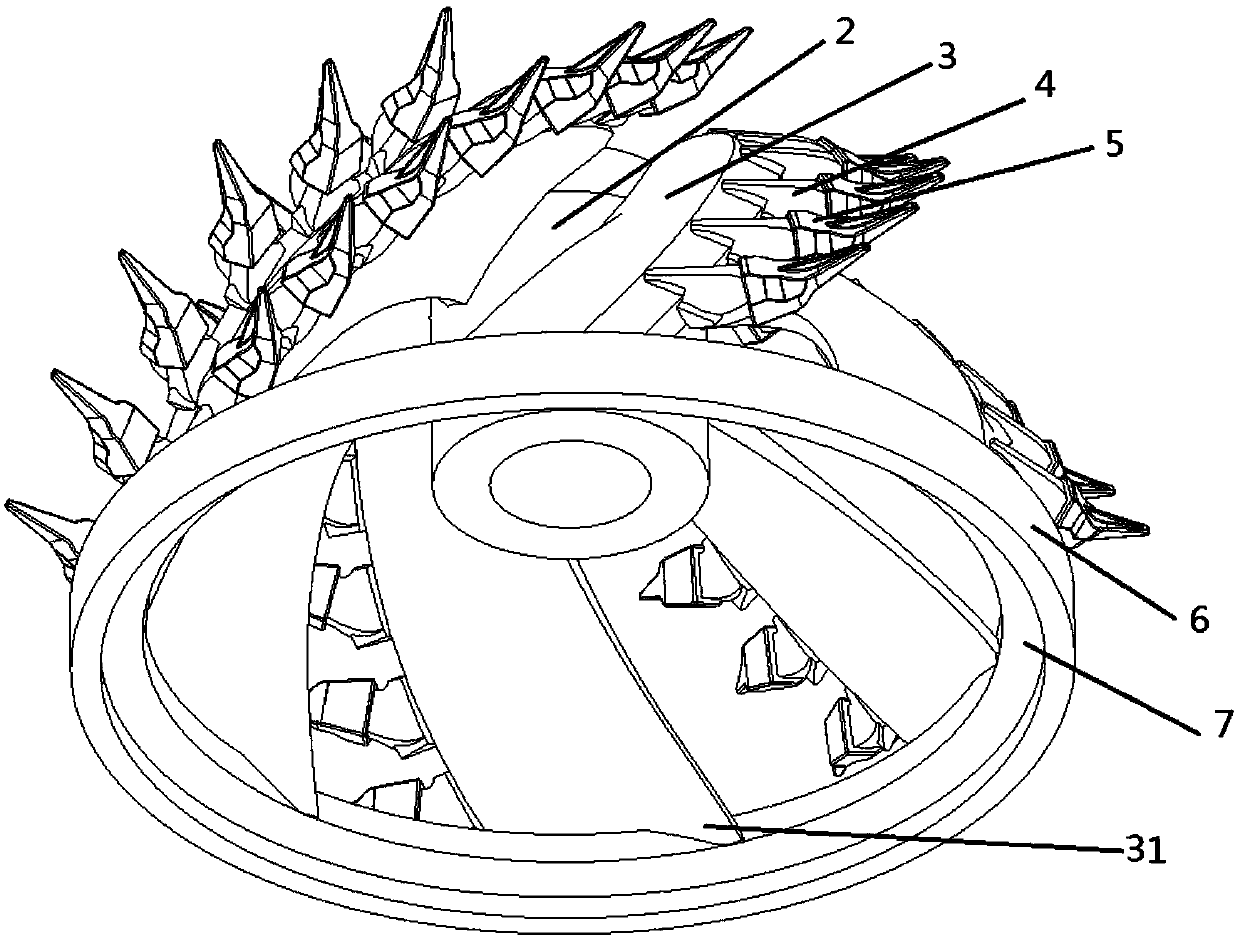

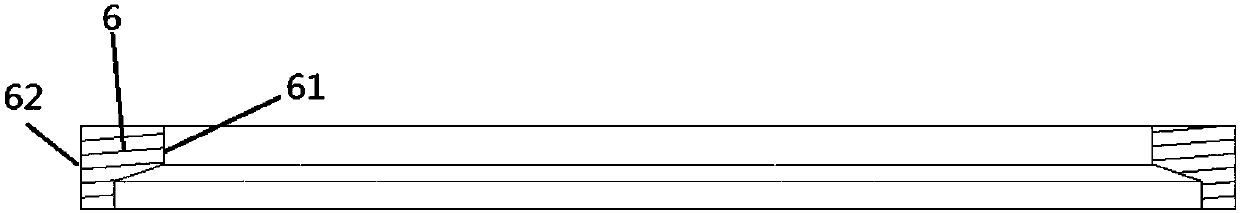

[0014] see Figure 1 to Figure 4 , a powerful soil-breaking reamer for a dredger, comprising a sealing plate 1, a cutter arm 3, a reamer hub 2, a cutter ring 6, cutter teeth 5, and a tooth seat 4, characterized in that the distance between the lower edge of the cutter ring 6 and the reamer The vertical distance of the upper edge of the hub is reduced from the original 1200mm to 1051mm; the linear shape of the knife arm is cone-shaped, and its taper is 4:5; the lower end of the knife arm extends to the inner side of the knife ring and is welded together; The diameter of the cutter ring is reduced from the original 2000mm to 1860mm; the outer edge of the cutter ring is welded with a retainer wear-resistant plate; the inner structure of the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com