Novel speed reduction clutch of intelligent washing machine

A deceleration clutch and washing machine technology, applied in the field of clutches, can solve the problems of not being able to normally apply large-capacity clutches for washing and dehydration, affecting the service life of clutch devices and washing machines, and being unable to apply to large-capacity washing machines, etc., to achieve simple structure and long service life , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

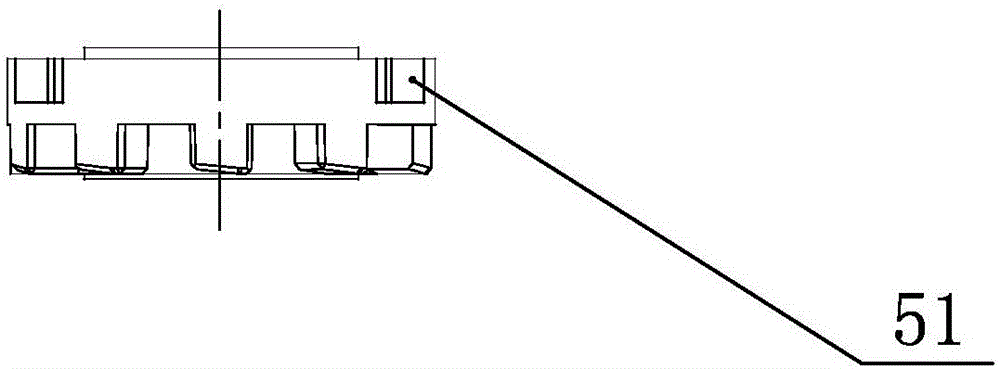

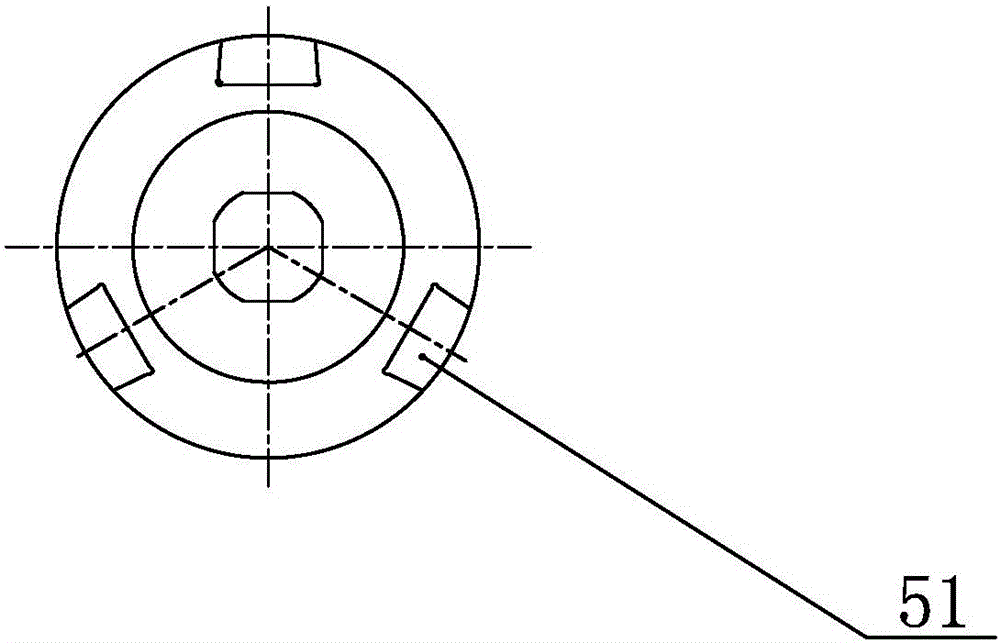

[0016] see figure 1 , figure 2 and image 3 , a new deceleration clutch for an intelligent washing machine disclosed in the present invention, comprising a lower housing 1, an upper housing 2, a brake wheel cover 3, a connecting disc 4, and a torque transmission sleeve 5, and the lower housing 1 is set with a system The driving wheel cover 3 and the brake wheel cover 3 are provided with an input shaft 6, the brake wheel cover 3 and the input shaft 6 are coaxially arranged, the torque transmission sleeve 5 is sleeved on the input shaft 6, and the torque transmission shaft A groove 51 is provided on the outer wall of the sleeve 5, and a magnet is embedded in the groove 51, and the magnet is connected and installed in the groove 51 by magnetic force, and a positioning disc 7 is arranged on the lower side of the lower housing, so that The positioning plate 7 is provided with a Hall sensor mounting frame 8, the lower end surface of the positioning plate 7 is connected with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com