A kind of organic fiber reinforced friction material and its preparation method

A technology of organic fibers and friction materials, applied in the field of friction materials, can solve the problems of skin allergy, redness, itching, etc., and achieve the effects of good oxidation resistance, excellent friction and wear performance, and excellent thermal friction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

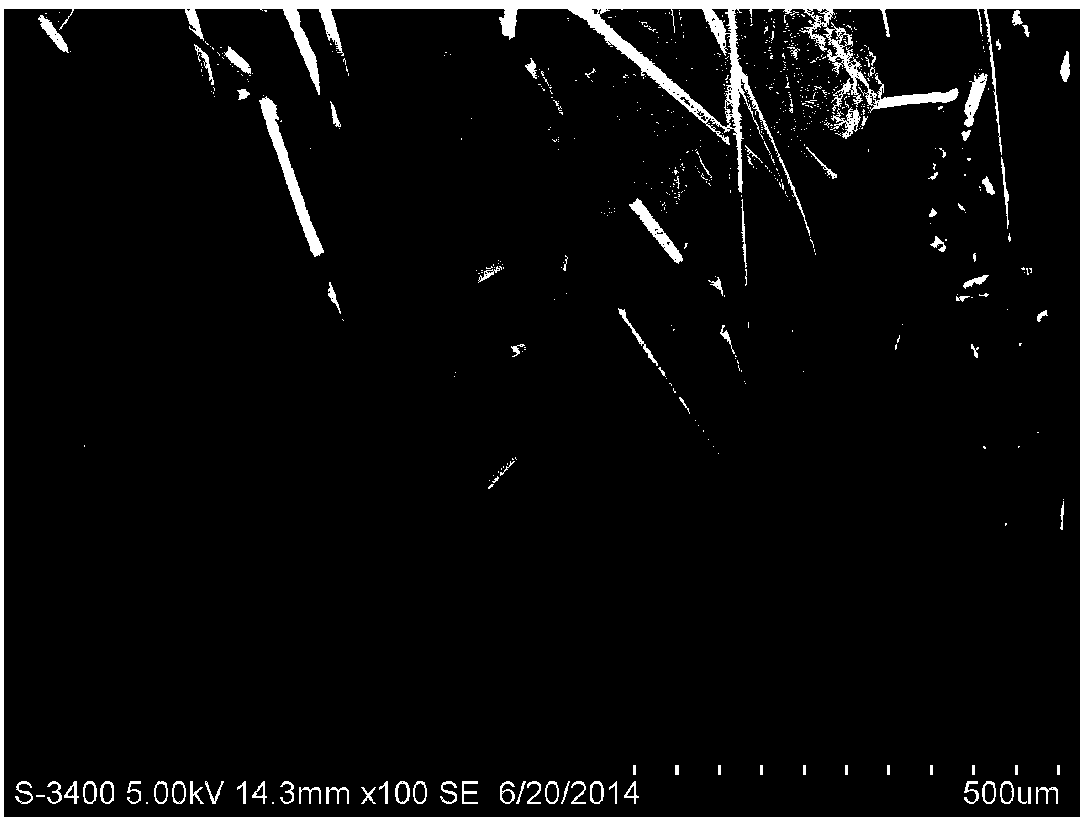

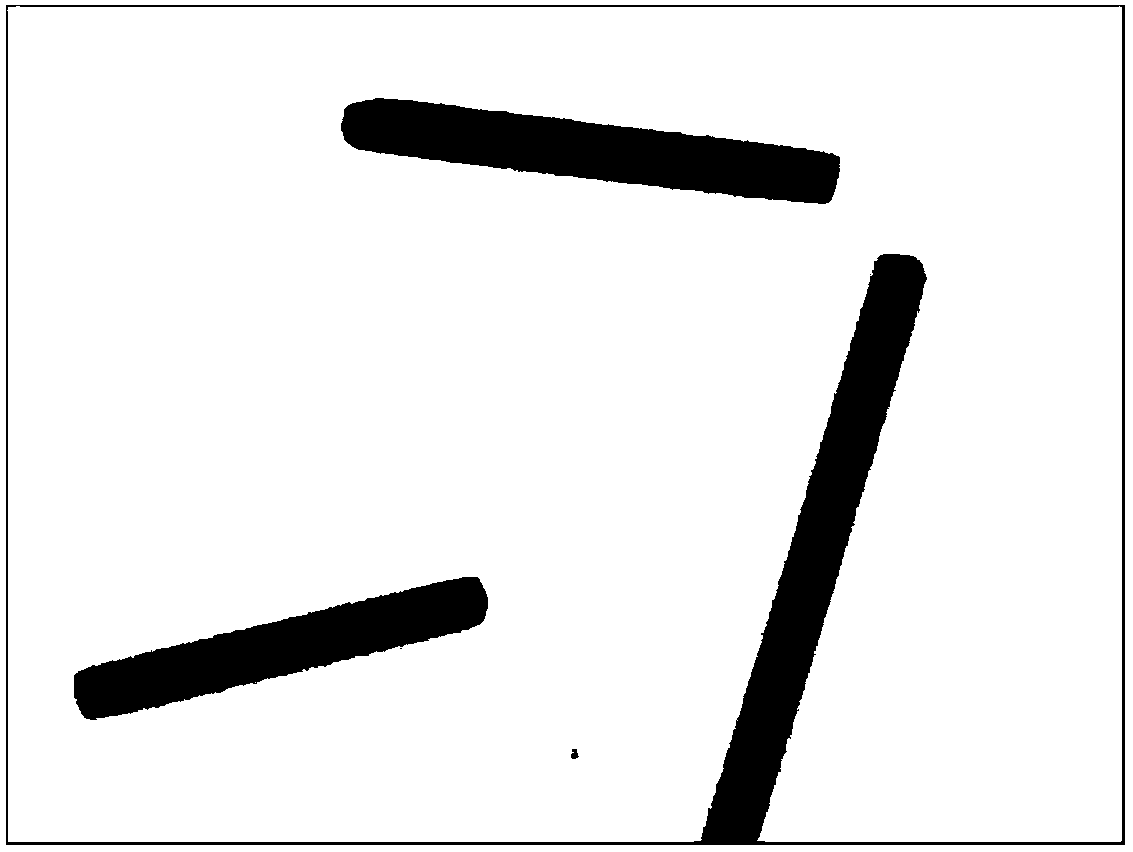

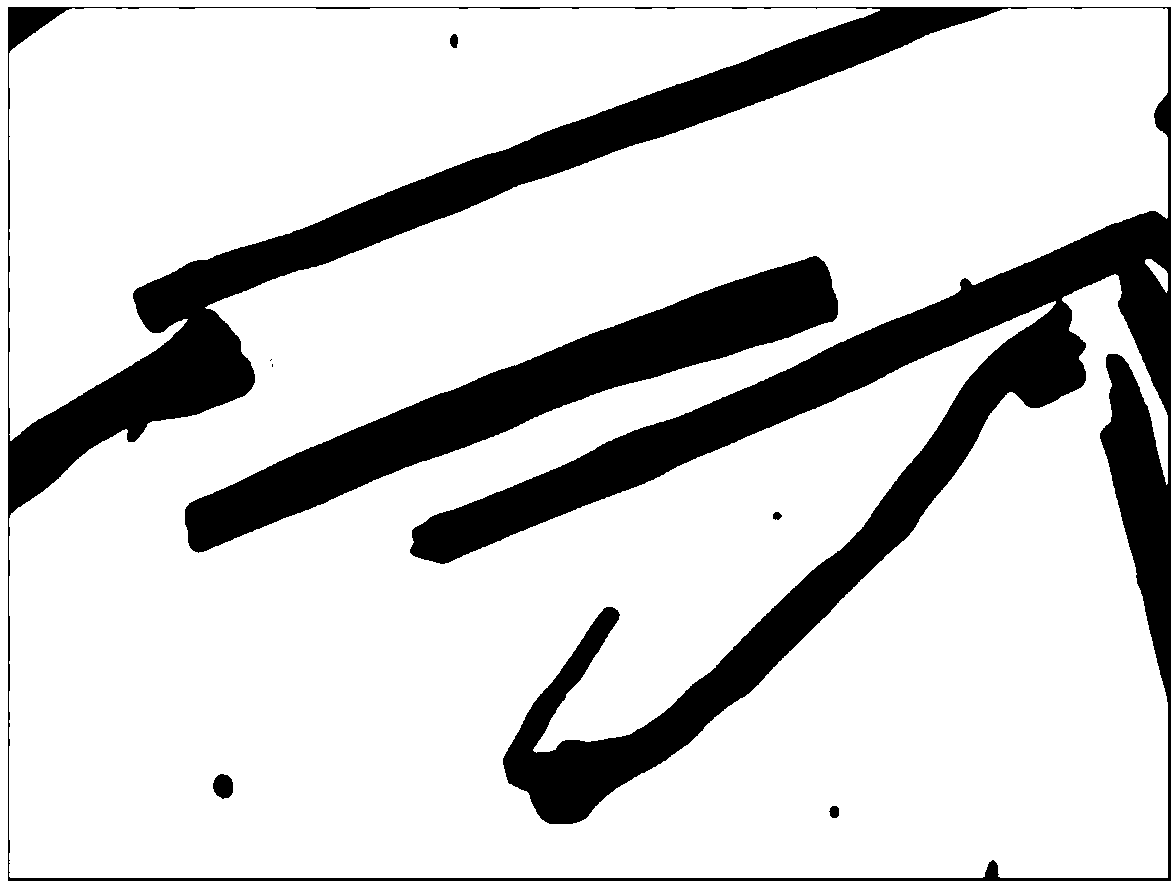

Image

Examples

Embodiment 1~3

[0039] An organic fiber reinforced friction material, the preparation method of which comprises the following steps:

[0040] 1) take each raw material according to the proportioning requirement described in Table 1;

[0041] 2) put the weighed raw material into the plow-rake type mixer and mix evenly to obtain the mixed raw material;

[0042] 3) Put the mixed raw materials in the mold for hot pressing; the pressure is 200kg / cm 2 , the temperature is 150°C, and the holding time is 5 minutes.

[0043]4) Place the molded product obtained in step 3) in an oven, heat from room temperature to 150°C for 1 hour, continue to heat up to 160°C for 1 hour, then heat up to 180°C for 6 hours; finally cool naturally to room temperature and take it out to obtain the organic Fiber reinforced friction material.

[0044] In the comparative example, polyacrylonitrile fiber and spun fiber were used to prepare the friction material. The ratio of the raw materials used is shown in Table 1, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com