Automatic bundling, woven bag filling, labeling, sewing and packaging machine for plastic pipes

An automatic bundling and plastic pipe technology, which is applied in the field of plastic pipe packaging, can solve the problems of the process affecting the sealing of the bag mouth, the bag is easily dented and shrunk, and the pipe bagging process is not smooth, so as to achieve smooth bagging and good bag expansion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

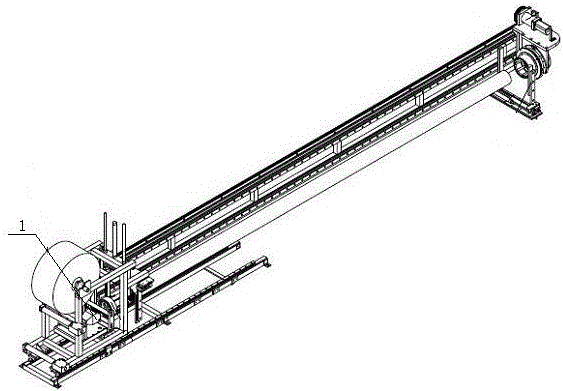

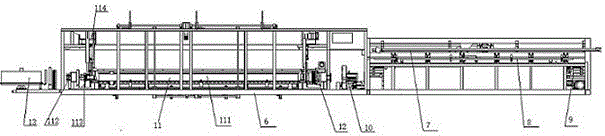

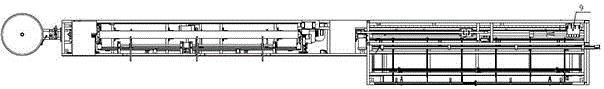

[0036] Such as Figures 2 to 4 As shown, a plastic pipe automatic binding sleeve woven bag labeling sewing packaging machine includes a frame 6, and the frame is provided with a turning frame 7 and a supporting and pressing mechanism 8, and the supporting and pressing mechanism 8 is behind the From right to left, a pushing mechanism 9, a binding mechanism 10 and a bagging mechanism 11 located on the same horizontal axis are sequentially arranged. The bagging mechanism 11 includes a bagging area 111 that can accommodate pipe materials. A bag expansion device 112 is provided, and it is used in conjunction with the bag gripper 12 provided on the bagging area. A label feeding device 113 is provided on one side of the bagging area 111, and a sewing device 114 is provided above the bagging area 111. , wherein the bag expansion device 112 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com