Suspension symmetric single shaft shoulder temperature measuring and single shaft shoulder and double shaft shoulder universal force measuring device

A force-measuring device and symmetrical technology, which is applied to non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of non-standard clamping, and achieve the effect of preventing butt joints from falling apart and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

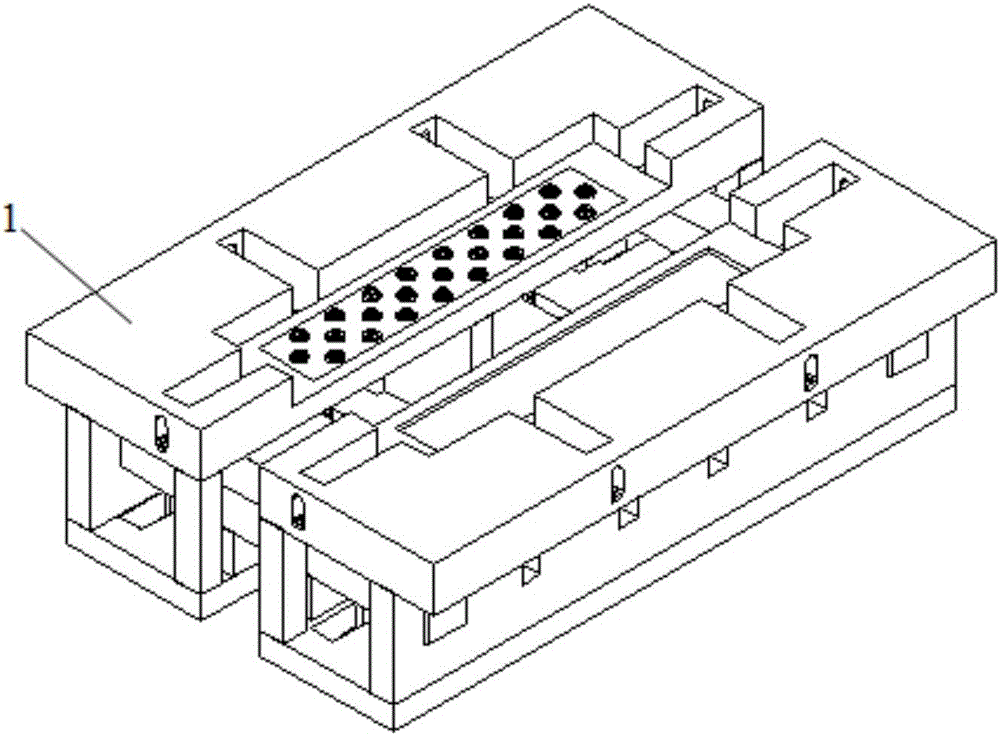

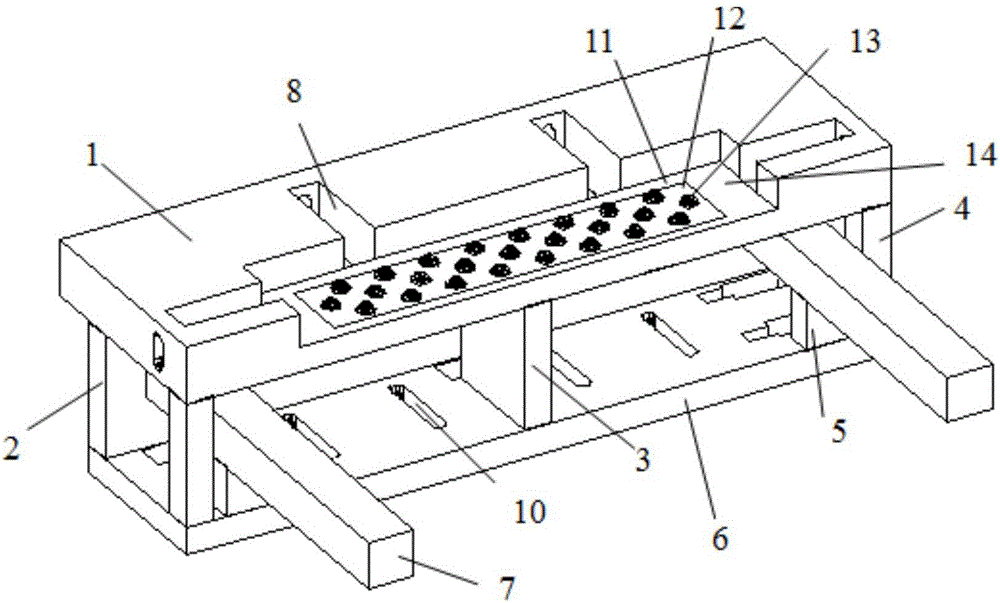

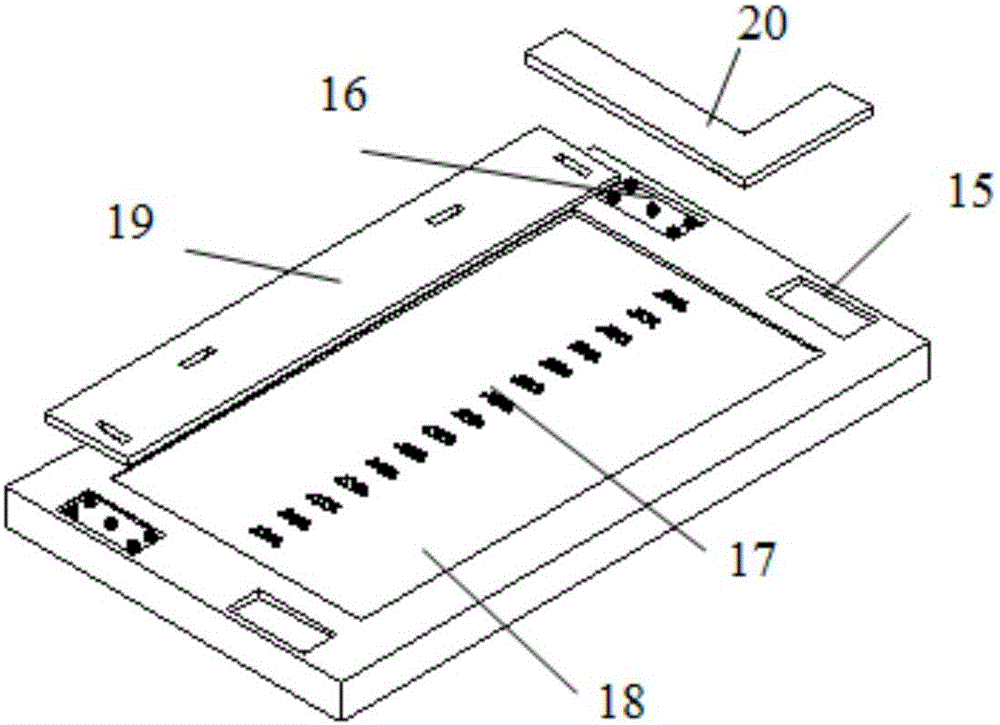

[0021] Such as Figure 1 to Figure 5 As shown, a suspension symmetrical single-shaft shoulder temperature measurement and single-dual-shaft universal force measuring device of the present invention includes an upper platform 1, a lower platform 6 and a support device connecting the upper platform 1 and the lower platform 6, the The upper platform 1 is provided with a groove 14, and the bottom of the groove 14 is provided with an accommodating groove, and a perforated sheet 11 is placed in the accommodating groove, and the perforated sheet 11 is provided with several first pits 13 for placing the first balls 12. The diameter of the ball 12 is greater than the depth of the first pit 13. A temperature measuring backing plate is installed on the first ball 12 in the groove 14. A thermocouple for measuring the welding temperature is installed on the temperature measuring backing plate. 14 is provided with two first sensor accommodating grooves 8 on each side around each side, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com