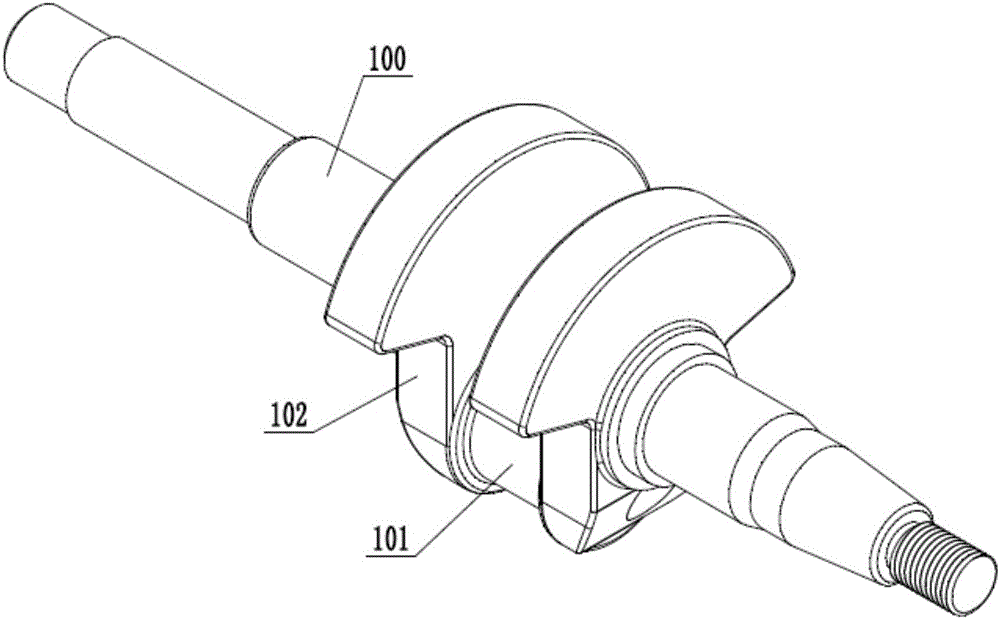

Crank throw positioning clamp

A technology for positioning fixtures and cranks, which is applied in the direction of expanding mandrels, etc., can solve the problems affecting machining accuracy, machining efficiency, machining safety, inconsistent crank arm clamping force F, and large dimensional errors, which is conducive to automated production, The effect of reducing impact damage and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

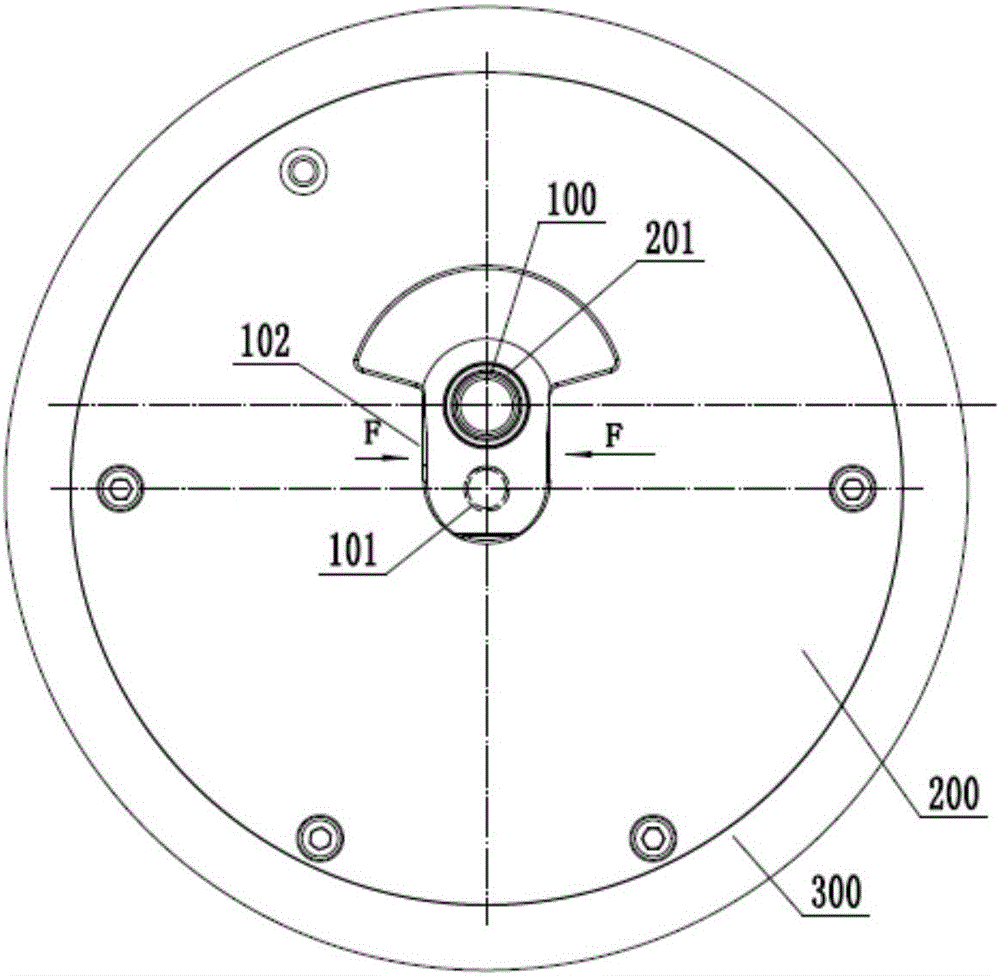

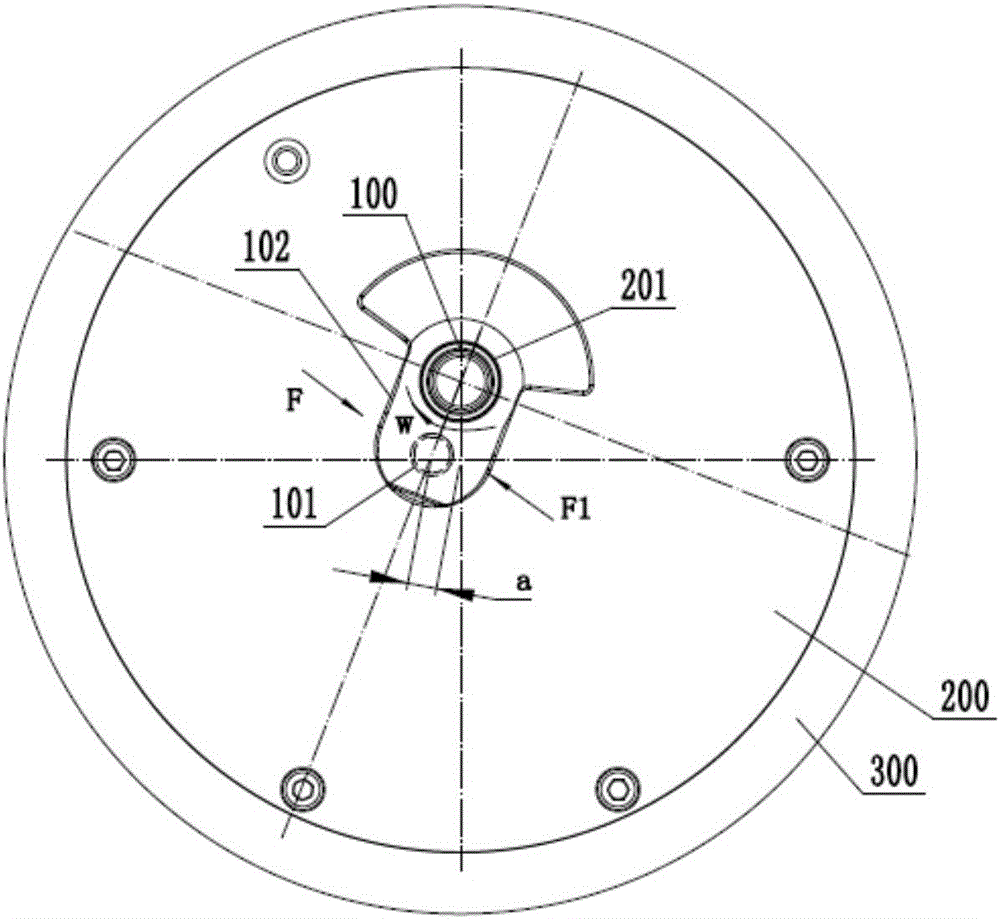

[0037] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0038] see Figure 4 , a bellcrank positioning fixture, including a positioning plate 1, a push rod 2, a taper sleeve 3, a spring jacket 4, a pair of positioning arms 5, a push plate 6, a retaining ring 7, a telescopic cylinder 8 and a connecting assembly 9.

[0039] combine Figure 4-5, wherein a first positioning hole 11 , a second positioning hole 12 and a mounting hole are opened in parallel on the positioning plate 1 , and the positioning plate 1 is installed on the outside of the connecting assembly 9 .

[0040] see Figure 4 , wherein, the ejector rod 2 is installed in the second positioning hole 12 with clearance fit, the outer end of the ejector rod 2 is provided with a tapered portion 21, and the inner end thereof passes through the second positioning hole 12 and is aligned with the pushing rod 2. Plates 6 are connected vertically.

[0041] comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com