Cobalt tetroxide microbelt with high peroxidase-like activity and stability and preparation method thereof

A technology of peroxidase and microribbons, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Reduce activity and other problems, achieve high peroxidase-like activity and stability, high product purity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

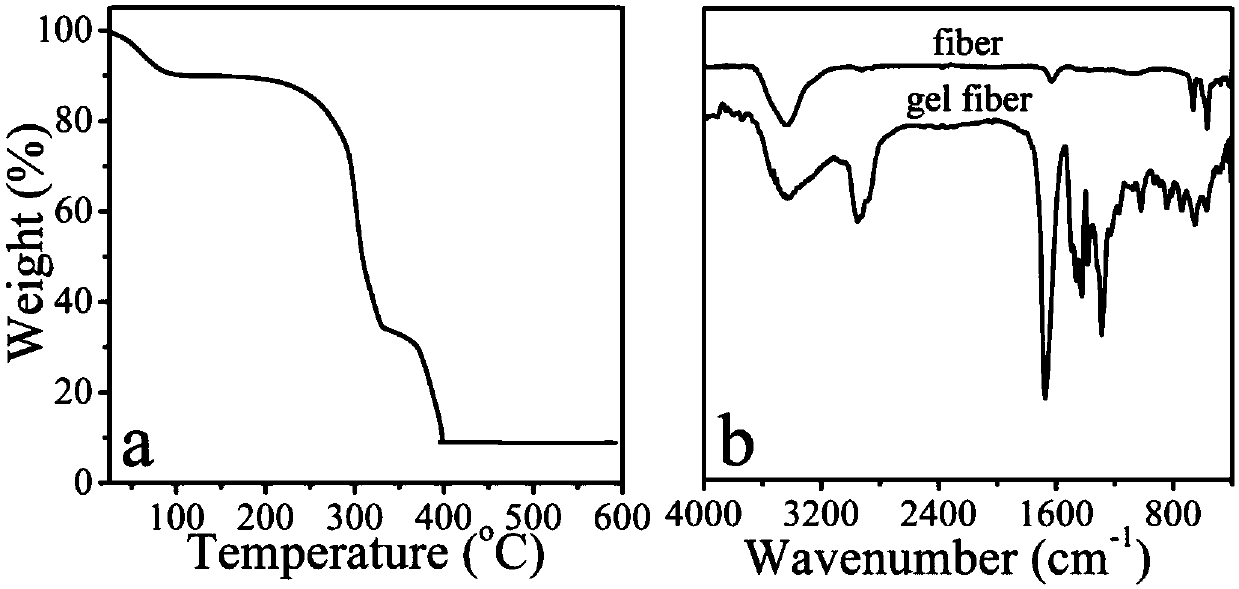

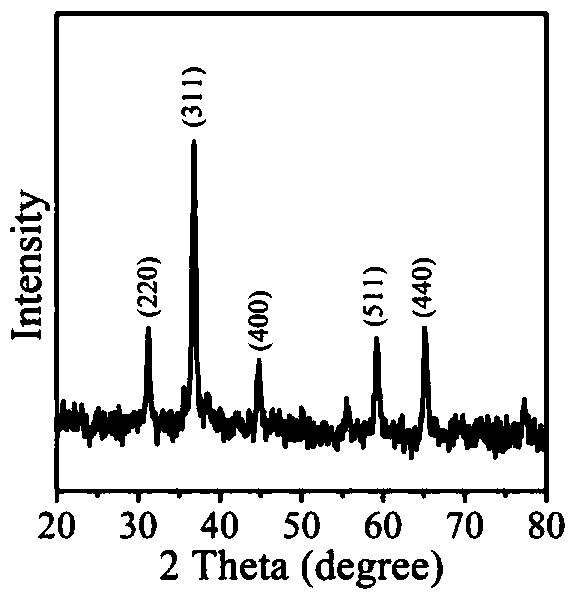

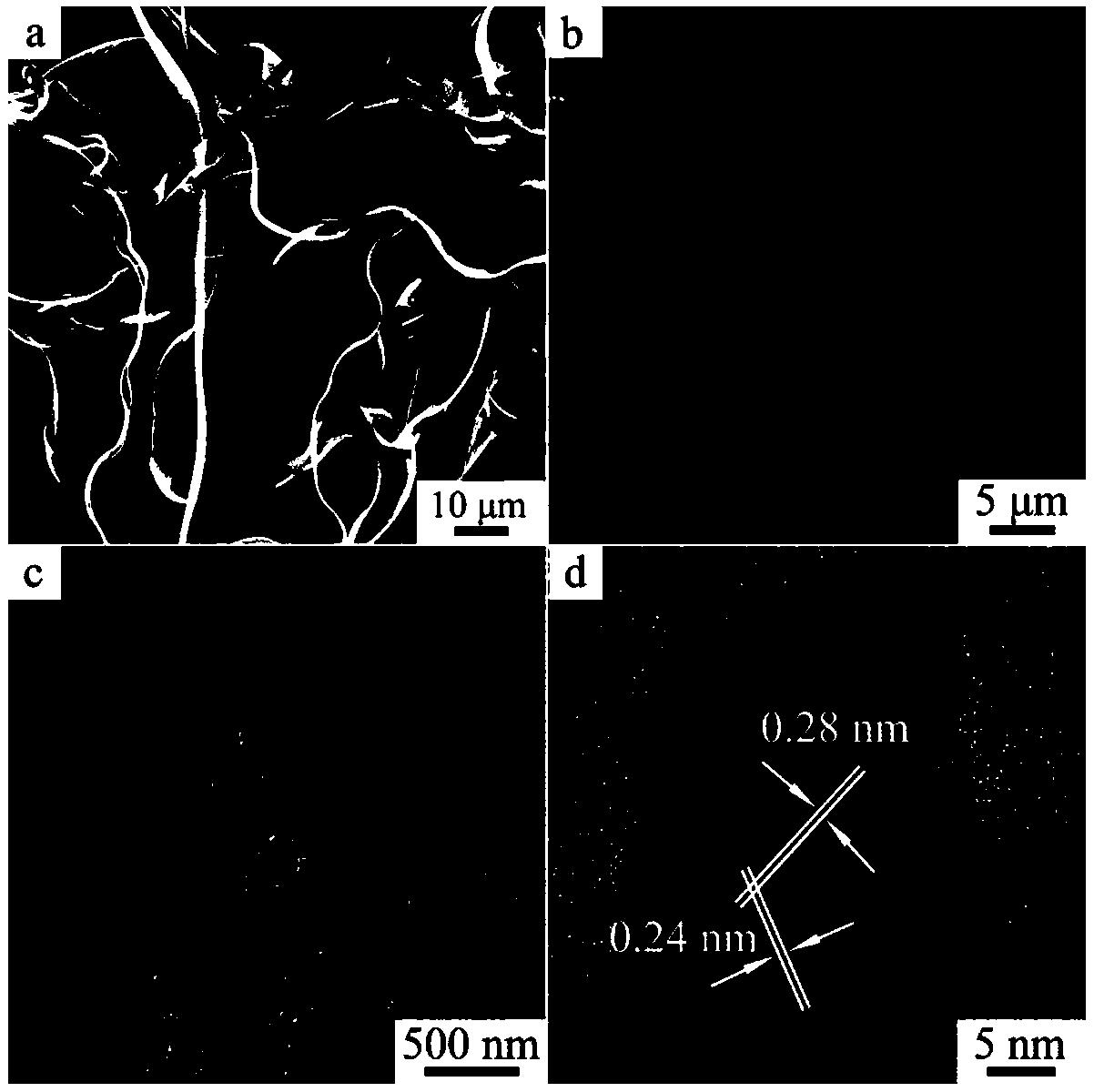

[0037] Weigh 1.0 g of polyvinylpyrrolidone (PVP), and dissolve it in 10 mL of ethanol under magnetic stirring. middle. After the PVP is completely dissolved, add 2mL cobalt nitrate solution (containing 0.45g Co(NO 3 ) 2 ·6H 2 O). When the sol is well mixed, transfer it to the syringe. Set the voltage of the electrospinning machine to 20kV, the receiving distance to 20cm, and the pump speed to 0.002mm / s. After the electrospinning was completed, the samples were collected and dried in an oven at 80 °C for at least 12 h. Finally, the final sample was calcined, and the calcination conditions were as follows: the room temperature was raised to 300°C at 1°C / min, and kept for 1h; then the temperature was raised to 400°C at 0.5°C / min, and kept for 2h.

Embodiment 2

[0039] Weigh 1.0 g of polyvinylpyrrolidone (PVP), and dissolve it in 8 mL of ethanol under magnetic stirring. middle. After the PVP is completely dissolved, add 2mL cobalt nitrate solution (containing 0.24g Co(NO3 ) 2 ·6H 2 O). When the sol is well mixed, transfer it to the syringe. Set the voltage of the electrospinning machine to 18kV, the receiving distance to 15cm, and the pumping speed to 0.003mm / s. After the electrospinning was completed, the samples were collected and dried in an oven at 70 °C for at least 12 h. Finally, the final sample was calcined, and the calcining conditions were as follows: room temperature was raised to 250°C at 0.8°C / min and kept for 1.5h; then raised to 350°C at 0.2°C / min and kept for 2.5h.

Embodiment 3

[0041] Weigh 1.0 g of polyvinylpyrrolidone (PVP), and dissolve it in 12 mL of ethanol under magnetic stirring. middle. After the PVP is completely dissolved, add 2mL cobalt nitrate solution (containing 0.57g Co(NO 3 ) 2 ·6H 2 O). When the sol is well mixed, transfer it to the syringe. Set the voltage of the electrospinning machine to 22kV, the receiving distance to 25cm, and the pumping speed to 0.005mm / s. After the electrospinning was completed, the samples were collected and dried in an oven at 90 °C for at least 12 h. Finally, the final sample was calcined. The calcination conditions were as follows: the room temperature was raised to 350°C at 3°C / min and kept for 0.5h; then the temperature was raised to 450°C at 0.8°C / min and kept for 1.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com