Novel polysaccharide cellulose medical glue with high mechanical strength and wound healing promotion and preparation method thereof

A technology of mechanical strength and wound healing, applied in the field of biomedical glue, can solve the problems of promoting wound healing and antibacterial, insufficient wound repair, no protrusion, etc., to achieve the effect of promoting wound repair, promoting wound healing, and reducing scar formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

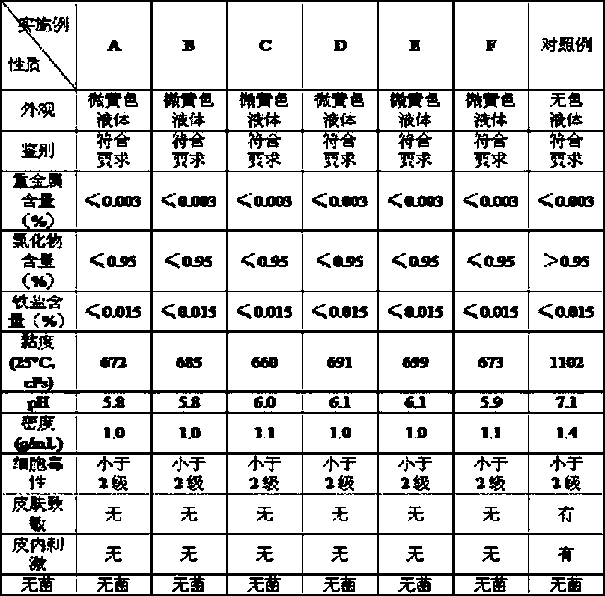

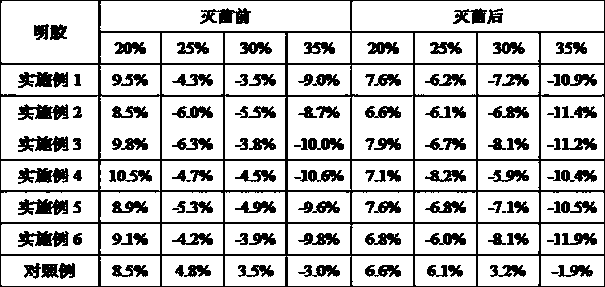

Examples

preparation example Construction

[0050] In one embodiment, the polyurethane modified starch adhesive is prepared by the following method:

[0051] (1) Preparation of polyurethane biuret

[0052] Add α-cyanoacrylate and polyisocyanate biuret according to n(NCO):n(OH) =1.6:1, add them into the beaker, stir well, then add α-cyanoacrylate and polyisocyanate biuret Equal quality of water, stir evenly to obtain polyurethane biuret.

[0053] (2) Preparation of polyurethane modified starch adhesive

[0054]Add 70g of purified water and 15g of starch into a water bath heating pot equipped with a mixer and a thermometer, heat and stir for about half an hour, control the temperature at 50-65°C, add 5g of hydrogen peroxide, and oxidize for more than half an hour, then control the temperature at 80 -90°C, slowly add 5g of polyurethane biuret, control the temperature at 80-90°C for polycondensation reaction for 1-2h, and the viscosity reaches 300mPa.s.

[0055] In one embodiment, the alpha-cyanoacrylate is one of octyl-...

Embodiment 1

[0066] (1) Add α-cyanoacrylate and polyisocyanate biuret according to n(NCO):n(OH) =1.6:1, add to the beaker and stir evenly, then add α-cyanoacrylate and polyisocyanate biuret Water of urea quality, stir evenly to obtain polyurethane biuret.

[0067] (2) Add 14g of purified water and 3g of starch into a water bath heating pot equipped with a mixer and a thermometer, heat and stir for about half an hour, control the temperature at 55°C, add 1g of hydrogen peroxide, and oxidize for more than half an hour, then control the temperature at Slowly add 1g of polyurethane biuret at 80°C, and conduct polycondensation reaction at 80°C for 1-2h, until the viscosity reaches 300mPa.s to obtain the polyurethane modified starch adhesive.

[0068] (3) Mix 1.8 g of sodium carboxymethyl cellulose, 0.04 g of astragalus polysaccharide, 1.5 g of polyurethane modified starch adhesive, and 1.5 g of sodium alginate, heat up to 50°C, add 95.16 g of water for injection and stir until Melt, and wait f...

Embodiment 2

[0070] (1) Add α-cyanoacrylate and polyisocyanate biuret according to n(NCO):n(OH) =1.6:1, add to the beaker and stir evenly, then add α-cyanoacrylate and polyisocyanate biuret Water of urea quality, stir evenly to obtain polyurethane biuret.

[0071] (2) Add 13g of purified water and 3g of starch into a water bath heating pot equipped with a mixer and a thermometer, heat and stir for about half an hour, control the temperature at 65°C, add 1g of hydrogen peroxide, and oxidize for more than half an hour, then control the temperature at At 90°C, slowly add 1g of polyurethane biuret, and conduct polycondensation reaction at 90°C for 1-2h, until the viscosity reaches 300mPa.s to obtain the polyurethane modified starch adhesive.

[0072] (3) Mix 1.5g sodium carboxymethylcellulose, 0.06g astragalus polysaccharide, 0.5g polyurethane modified starch adhesive, and 0.5g sodium alginate, heat up to 50°C, add 97.44g water for injection and stir until Melt, and wait for natural cooling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com