Exhaust gas recirculation system and method, engine and use of exhaust gas recirculation system

An exhaust gas recirculation and engine technology, which is applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems of adjusting the cleaning amount, and achieve the effect of cleaning, high efficiency and high cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

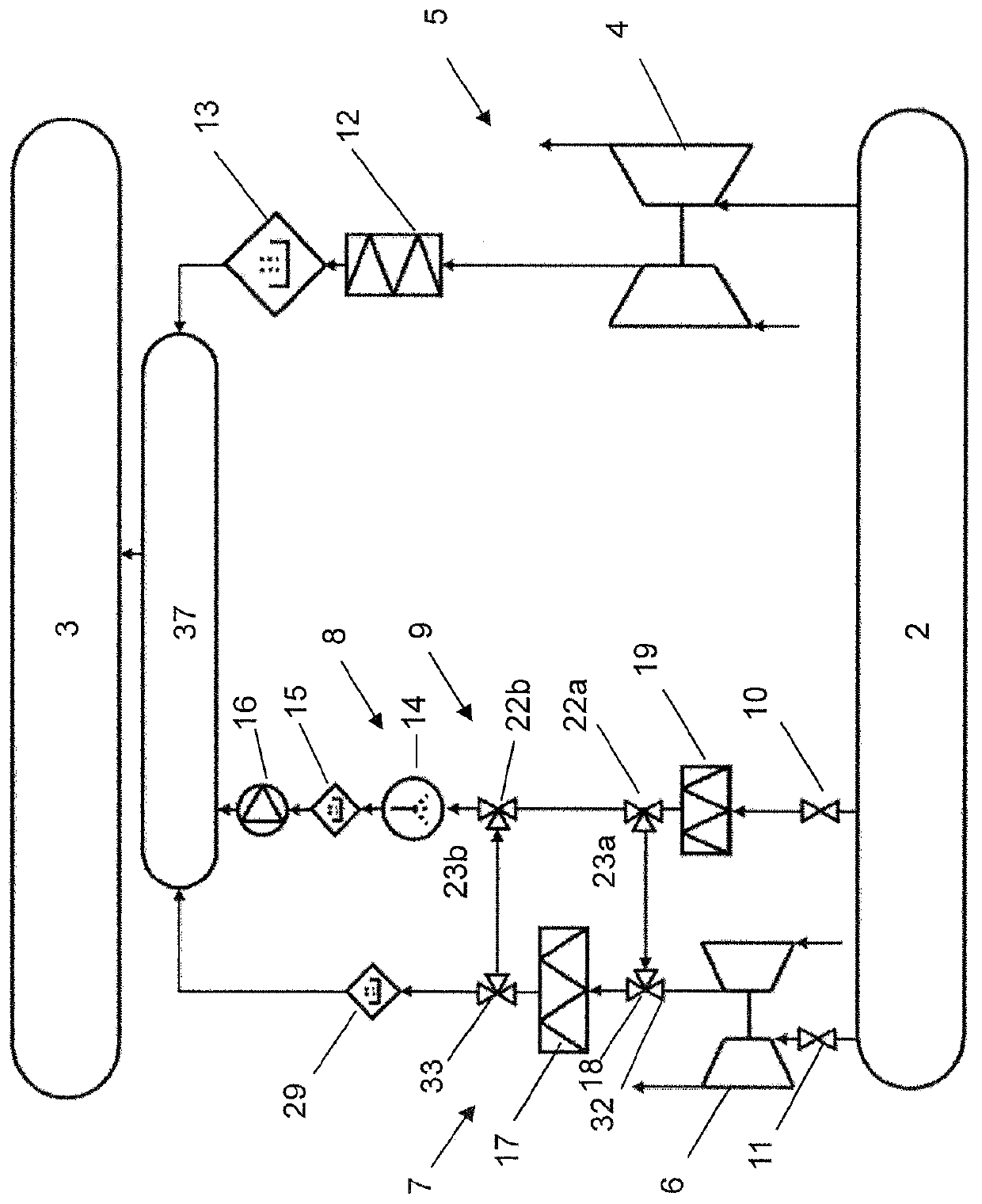

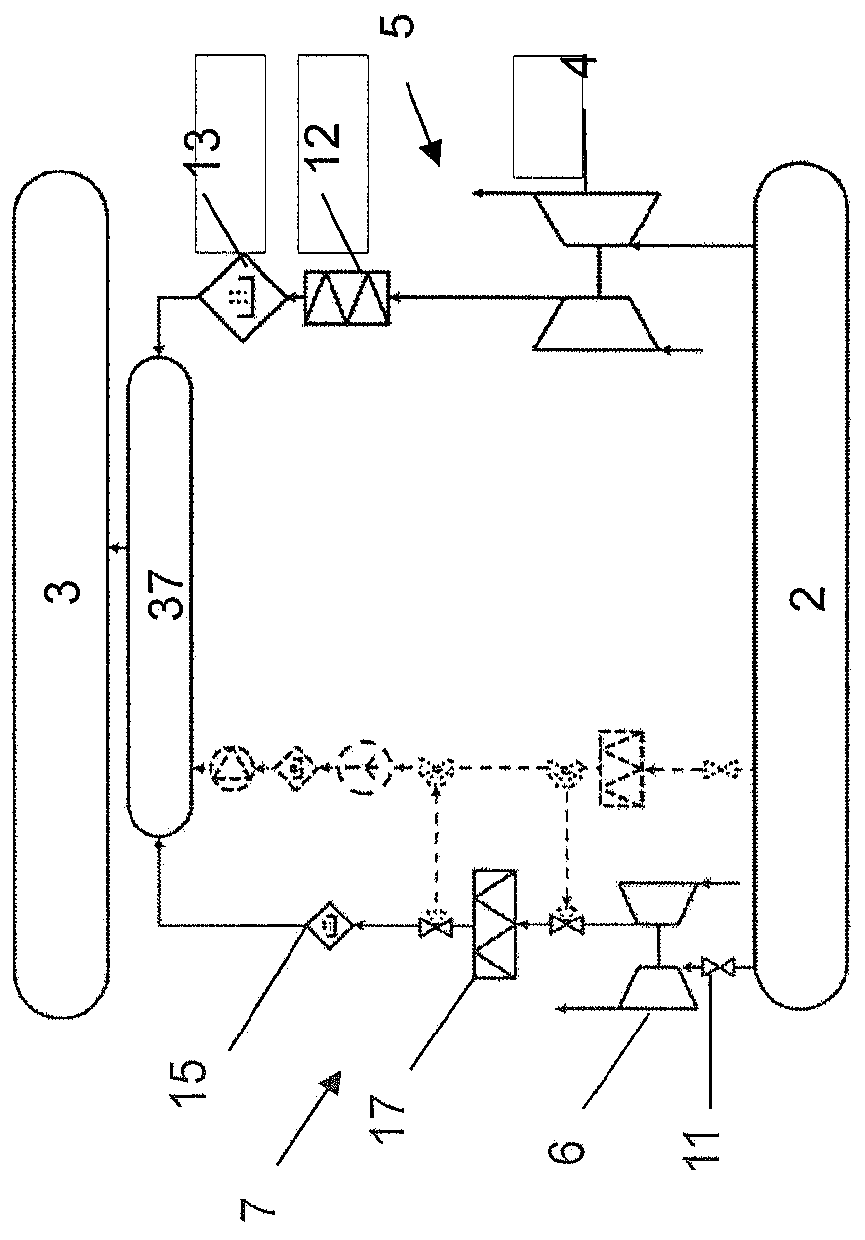

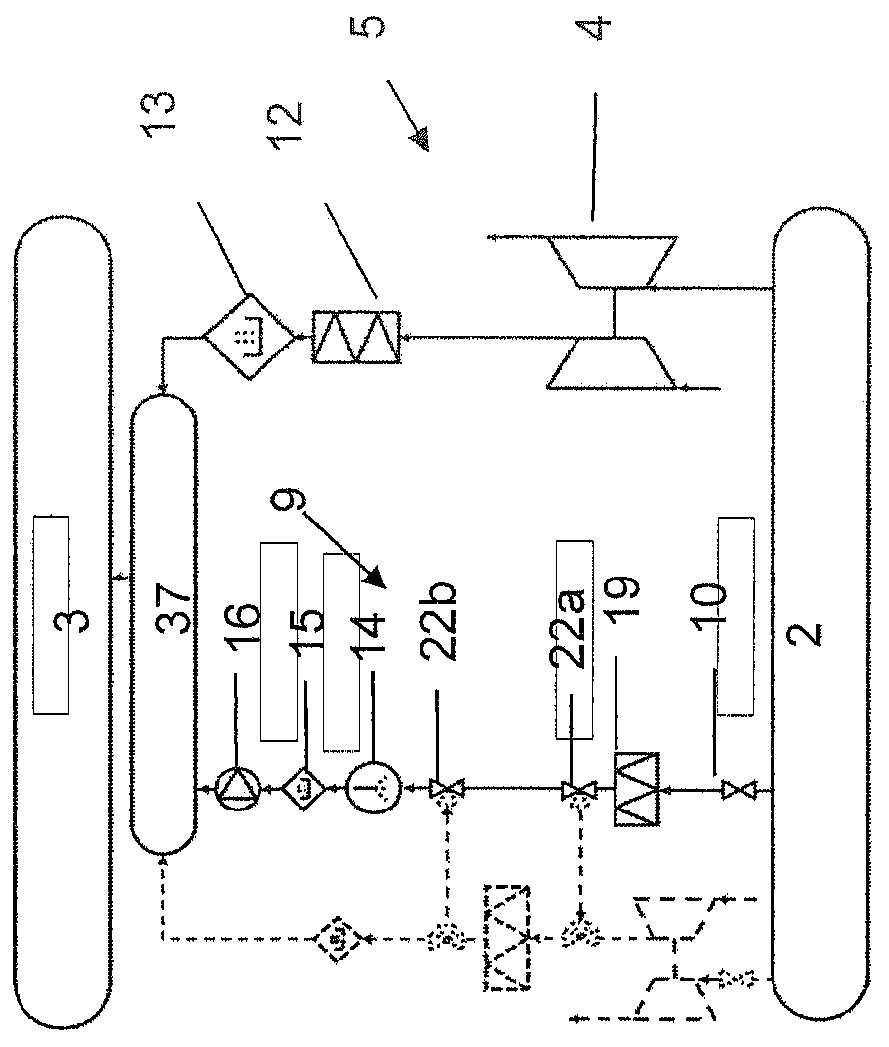

[0114] figure 1 A schematic diagram of a first embodiment of the system 1 is shown. The system 1 for exhaust gas recirculation is arranged between the exhaust gas outlet 2 and the air inlet 3. The exhaust gas leaving the exhaust outlet 2 is partially introduced into the first turbocharger 4 that uses the exhaust gas to power the turbine, and fresh air is sucked into the compressor driven by the turbine of the first turbocharger 4 . The compressed air is introduced into the first cooler 12 and then passes through the first water mist trap 13. From the first water mist trap 13 onwards, compressed air is introduced into the mixing device 37. Another part of the exhaust gas leaving the exhaust gas outlet 2 is introduced through the second turbocharger 6, similar to the first turbocharger 4, where the exhaust gas drives the turbine. Upstream of the turbine of the second turbocharger 6, a second inlet valve 11 is arranged. The fresh air compressed by the compressor of the turboch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com