Skin-masking material

A technology for covering materials and skin, applied to skin diseases, preparations for skin care, medical preparations with non-active ingredients, etc., can solve the problems of cosmetics shedding, inability to cover heterogeneous parts with confidence, peeling, etc., to achieve makeup sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

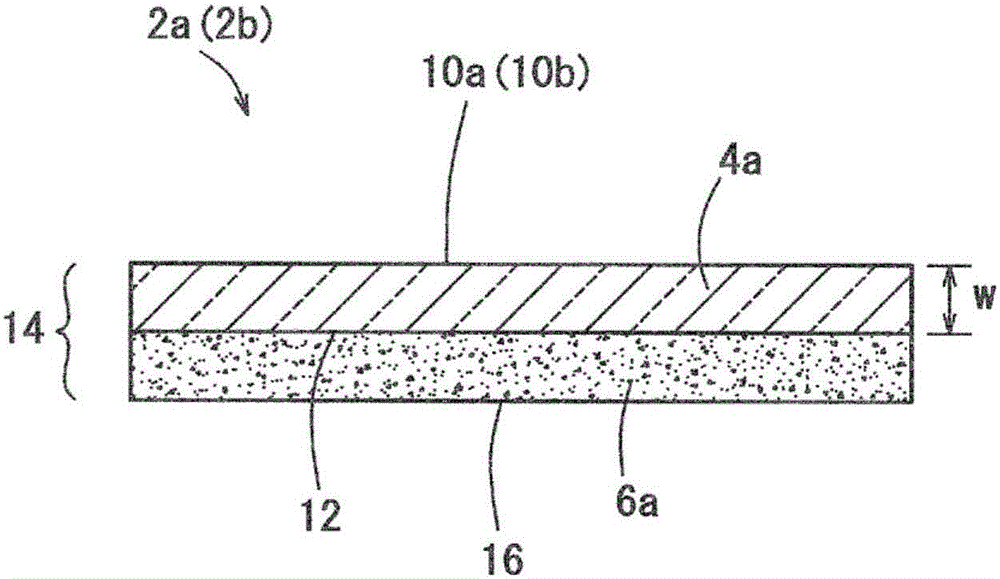

[0035] Such as figure 1 As shown, the skin masking material 2a of the first embodiment is a laminate 14 including a film layer 4a and an adhesive layer 6a. The adhesive layer 6a is laminated on one side 12 of the film layer 4a.

[0036] The film layer 4a has stretchability. When the skin masking material 2a is attached to the skin, at least a part of the film layer 4a is stretched following the curved surface of the skin. The skin masking material 2a can be attached so that the entire skin-contacting surface 16 opposite to the one surface 12 of the adhesive layer 6a closely adheres to the curved skin.

[0037] In order to impart stretchability to the film layer 4a, a film having a tensile modulus of 0.2 to 5 MPa is preferably used as a raw material of the film layer 4a. When the tensile modulus is less than 0.2 MPa, the film layer 4a expands and contracts more than necessary, making it difficult to pick and peel the skin masking material 2a from the skin with fingertips. ...

Embodiment approach 2

[0060] In this specification, the same code|symbol shown in each drawing represents the same or the same member. about figure 1 The skin-shielding material 2b according to Embodiment 2 shown will be described with respect to the different configurations and operational effects from the skin-shielding material 2a. The Rz of the other surface 10b of the skin masking material 2b is 6 μm≤Rz≤40 μm, and Rz≤w.

[0061] Compared with the conventional skin masking material, the skin masking material 2b has a larger unevenness formed on the other surface 10b, and the powder contained in cosmetics is easily retained in the concave portion. Furthermore, the Rz of the other surface 10b of the skin masking material 2b is Rz≦40μm, so the level difference of the unevenness will not be too large, and it is extremely easy to wipe off the powder held in the concave portion. The user can easily touch up the makeup, so there is no need to carefully adjust the color.

[0062] Rz of the other su...

Embodiment approach

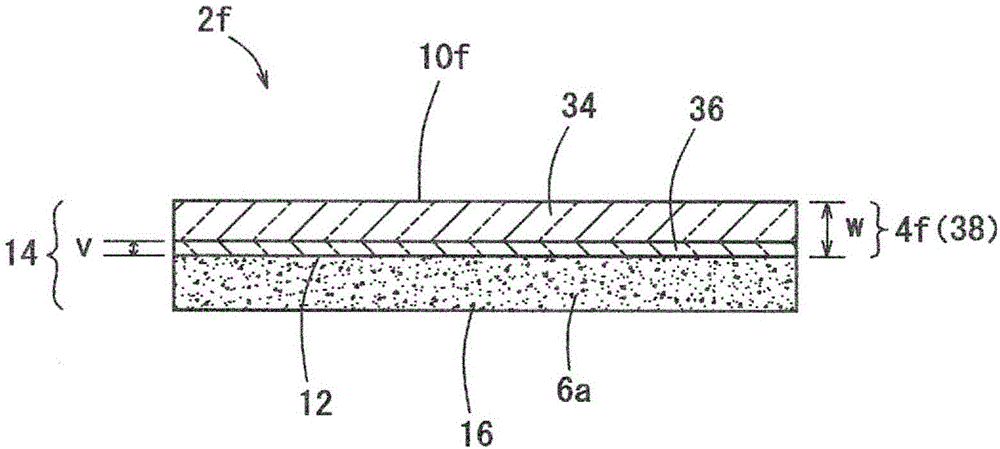

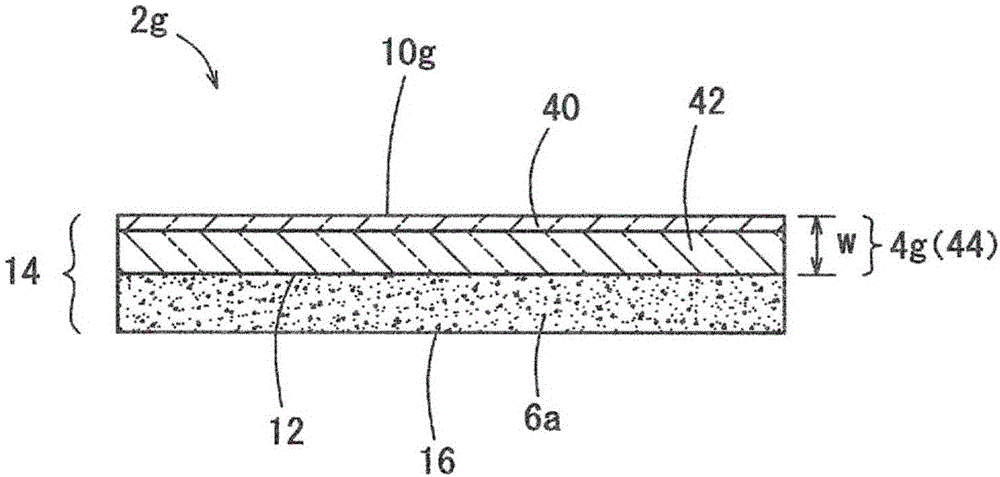

[0121] about Figure 2-5 The skin masking materials ( 2f , 2g , 2h , 2i , 2j ) of other shown embodiments will be described with respect to their different configurations and operational effects from the skin masking materials ( 2a , 2b ).

[0122] figure 2 The material of the film layer 4f in the shown skin masking material 2f is a composite film 38 in which a urethane film 34 having irregularities and a hydrophobic film 36 are laminated. Examples of the material of the hydrophobic film 36 include hydrophobic synthetic resins selected from the group consisting of polyolefin resins, thermoplastic elastomers, rubber-based resins, and mixtures thereof. Here, examples of thermoplastic elastomers include styrene-isoprene-styrene block copolymers, styrene-butadiene copolymers, and their modified products based on acrylics and the like. In addition, examples of the rubber-based resin here include isoprene rubber, butyl rubber, polyisobutylene, and modified products thereof. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com