Constant-current driving system of compressor

A constant current drive and compressor technology, applied in control/regulation systems, DC power input conversion to DC power output, instruments, etc., can solve the problems of large current fluctuations, shortened compressor life, and insufficient stability of compressor operating current, etc. problem, to achieve the effect of reducing the current fluctuation range, prolonging the service life and stabilizing the working current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

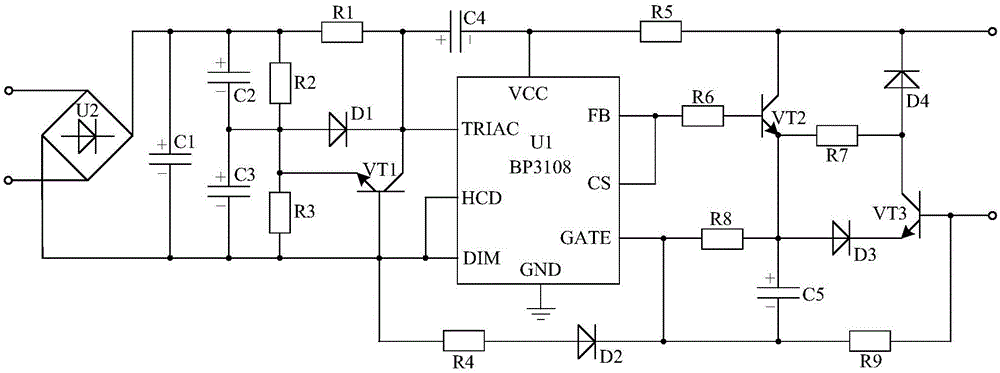

[0015] Such as figure 1 As shown, the constant current driving system of the present invention is mainly composed of a driving chip U1, a resistor R4, a capacitor C4, a diode D2, a resistor R5, a constant current source circuit, and a driving circuit. Specifically, the anode of the capacitor C4 is connected to the TRIAC pin of the driver chip U1, and its cathode is connected to the VCC pin of the driver chip U1. The P pole of the diode D2 is connected to the DIM pin of the driver chip U1 through the resistor R4, and the N pole of the diode D2 is connected to the GATE pin of the driver chip U1. One end of the resistor R5 is connected to the VCC pin of the driving chip U1, and the other end is connected to the driving circuit. The HCD pin of the driver chip U1 is connected to the DIM pin, and the CS pin is connected to the FB pin. The constant current drive system of the present invention is mainly used for compressors, and the drive chip U1 is a BP3108 integrated chip.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com