Light-emitting display with straight and parallel fork gate-controlled mouth, sharp triangle top-type cathode structure and its manufacturing process

A technology of luminescent display and cathode structure, applied in cathode ray/electron beam tube fluorescent screen, image/graphic display tube, cathode ray tube/electron beam tube, etc., can solve the problem of reducing the luminous brightness and luminous intensity of luminescent display The effective emission area is small, the gate current is too large, etc., to achieve the effect of reducing the effective distance, reducing useless power loss, and reducing the working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

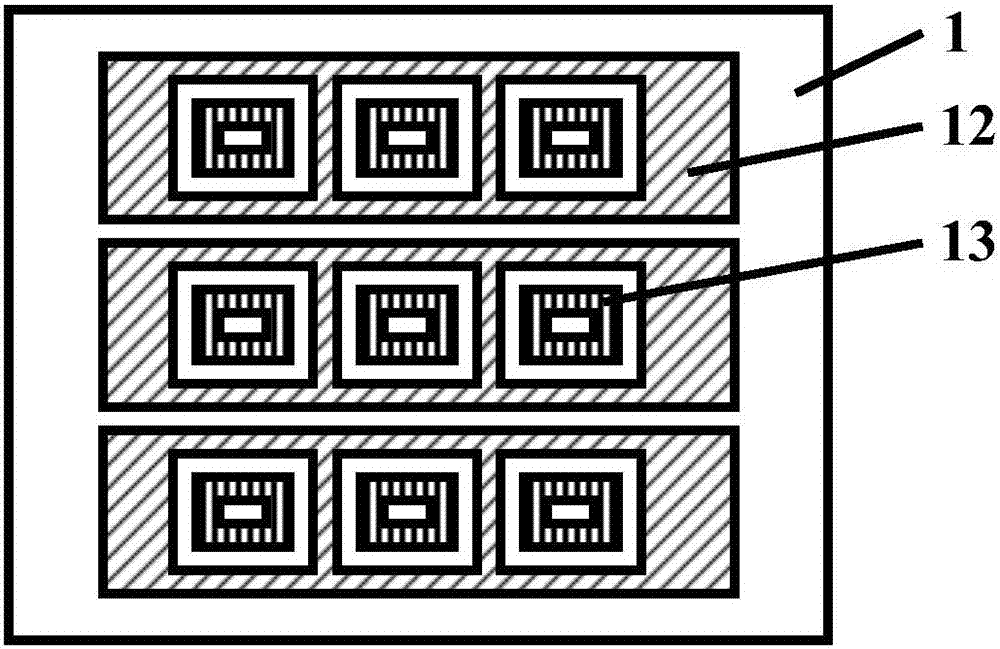

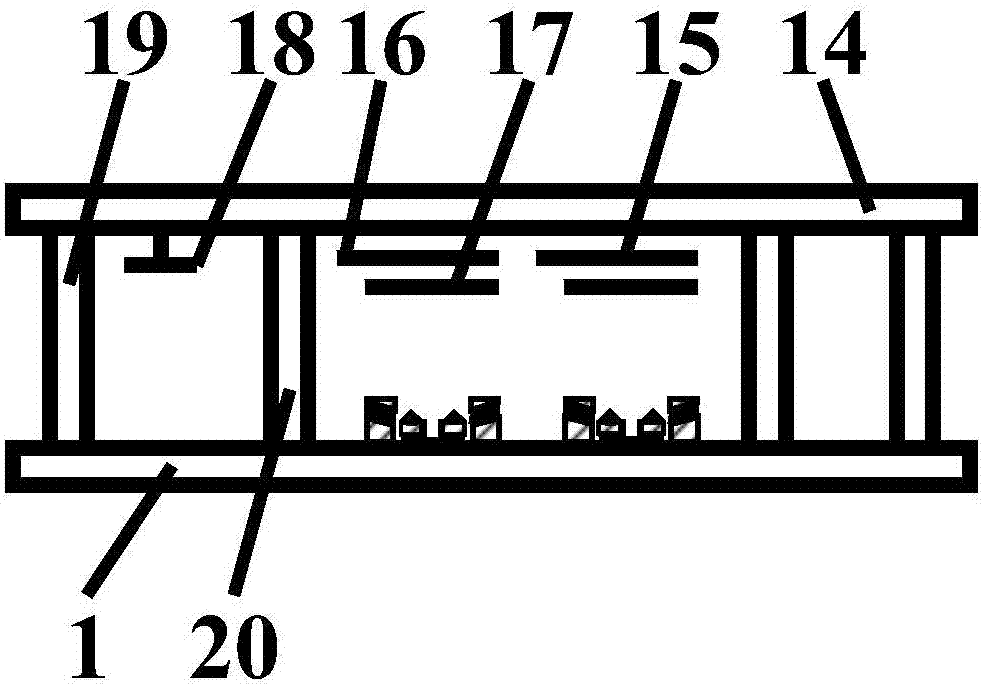

[0044] The light-emitting display of the oblique straight parallel fork gated mouth word pointy triangular top type cathode structure of the implementation is as follows figure 1 , figure 2 and image 3 Shown, comprise the vacuum chamber that is made of cathode encapsulation plate 1, anode encapsulation plate 14 and transparent glass frame 19; On anode encapsulation plate 14, anode conduction layer 15, phosphor layer 17 prepared on anode conduction layer 15 and The anode extension line layer 16 connected to the anode conductive layer 15; there is an oblique straight parallel fork gate control mouth pointed triangle top cathode structure on the cathode packaging plate 1; the support column 20 and the getter 18 auxiliary components located in the vacuum chamber.

[0045] Among them, the obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com