Method for optimizing working parameters of centrifugal fertilizer spreading plate

A technology of working parameters and optimization methods, which is applied in the directions of multi-objective optimization, electrical digital data processing, special data processing applications, etc., can solve the problems of high labor intensity, inability to work with wide fertilizer spread, and low work efficiency, so as to improve uniformity performance and stability, a wide range of fertilization operations, and the effect of reducing the cost of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

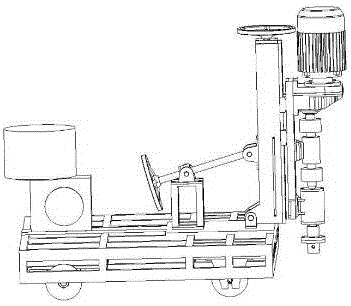

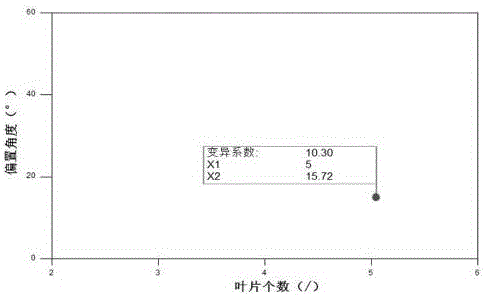

[0022] Taking urea as the test fertilizer, walking speed, offset angle and leaf number as the influencing factors, and the distribution variation coefficient of the number of fertilizer particles in each collection box as the evaluation index of fertilization effect, a quadratic regression with three factors and three levels was used Combination design test method of cross rotation center, fertilization effect test is carried out on the tillage and fertilization test bench. Cultivation and fertilization test bench such as figure 1 As shown, the fertilizer granule collection box is as figure 2 shown. Among them, the three levels of walking speed are 0.4m / s, 0.6m / s, and 0.8m / s, the angle change levels of centrifugal disc blades are 0, 30, and 60, and the number of blades is adjusted to 2, 4, and 6 respectively.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com