Method for quickly analyzing bonding strength of side window of high-speed train

A technology for bonding strength and high-speed trains, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the size of the car body unit cannot be too large, the modification workload is huge, and the analysis cycle is prolonged, so as to reduce the The effects of repeated modeling, reduced workload, and improved computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The bonding strength of a certain side window of the motor car passenger compartment is calculated, and the method of the present invention is described in detail.

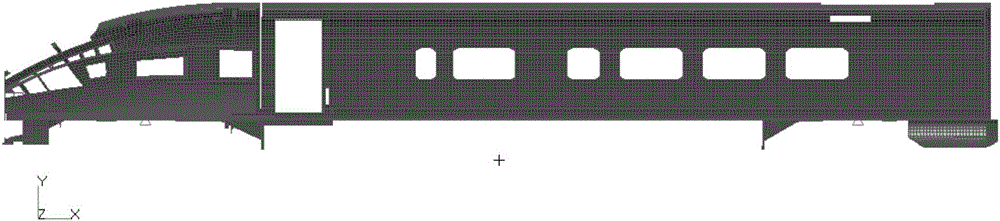

[0037] Step 1: Establish a large-scale element (80mm) finite element model of the car body, such as image 3 , the number of units is 202325, and the number of nodes is 113361.

[0038] Step 2: Establish a small-scale (8mm) unit finite element model of a side window (including adhesive, glass, and window frame) of the passenger compartment of the train, such as Figure 4 , the number of units is 12563, and the number of nodes is 13216.

[0039] Step 3: Under a certain working condition, carry out strength analysis on the large-scale finite element model of the car body to obtain the deformation of all nodes on the car body, such as Figure 5 .

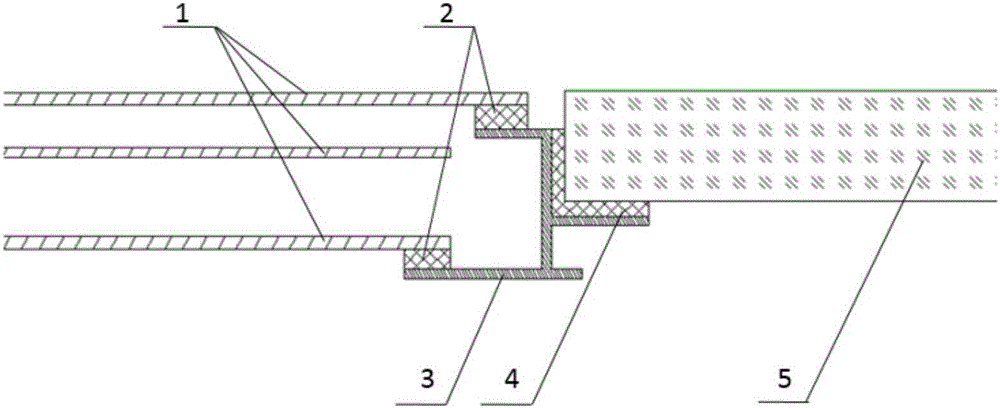

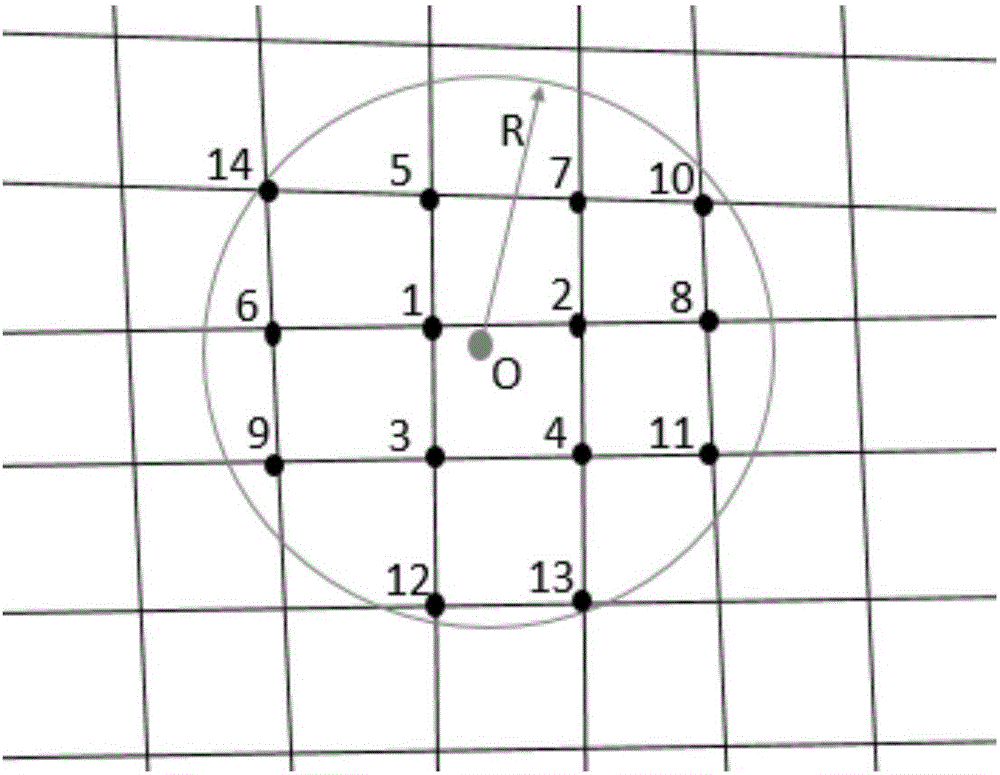

[0040] Step 4: Use the adhesive (2) on the upper surface of the finite element model (bonding the contact surface with the car body (1), the schematic diagram is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com