A Composite Sensor Array and Defect Quantification Method for Ultrasonic Internal Detection of Pipeline Defects

A technology of sensor array and ultrasonic sensor, which is applied in the direction of analyzing solids by using acoustic wave/ultrasonic wave/infrasonic wave, which can solve the problems of inability to give quantitative parameter information of small defects, inability to effectively detect small defects, and few types of detected defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention includes the following steps:

[0046] A composite array for ultrasonic internal detection of pipeline defects and a defect quantification method, including three parts: a composite ultrasonic sensor array structure design method, an ultrasonic sensor and the coordinate position determination method of the sound beam incident point, and a defect quantification method;

[0047] The structure design method of the composite ultrasonic sensor array:

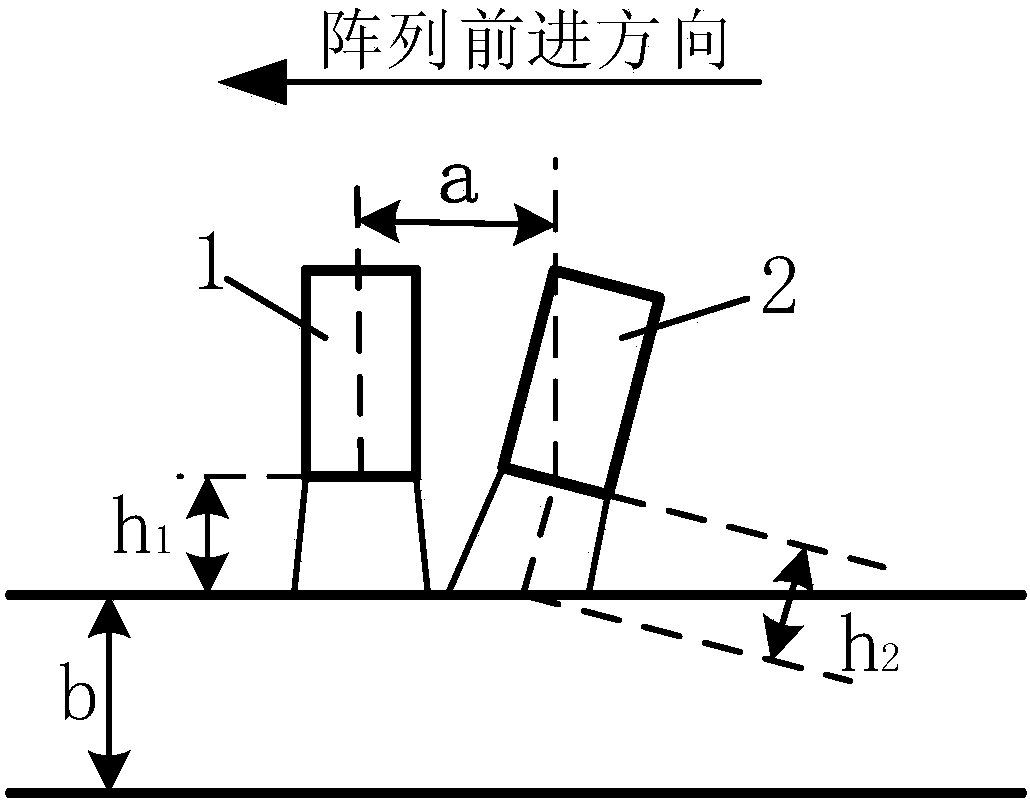

[0048] Step 1.1, use the pulsed ultrasonic sensor as the array detection unit, and use the propagation characteristics of a single sensor in the pipe wall as one of the array design basis;

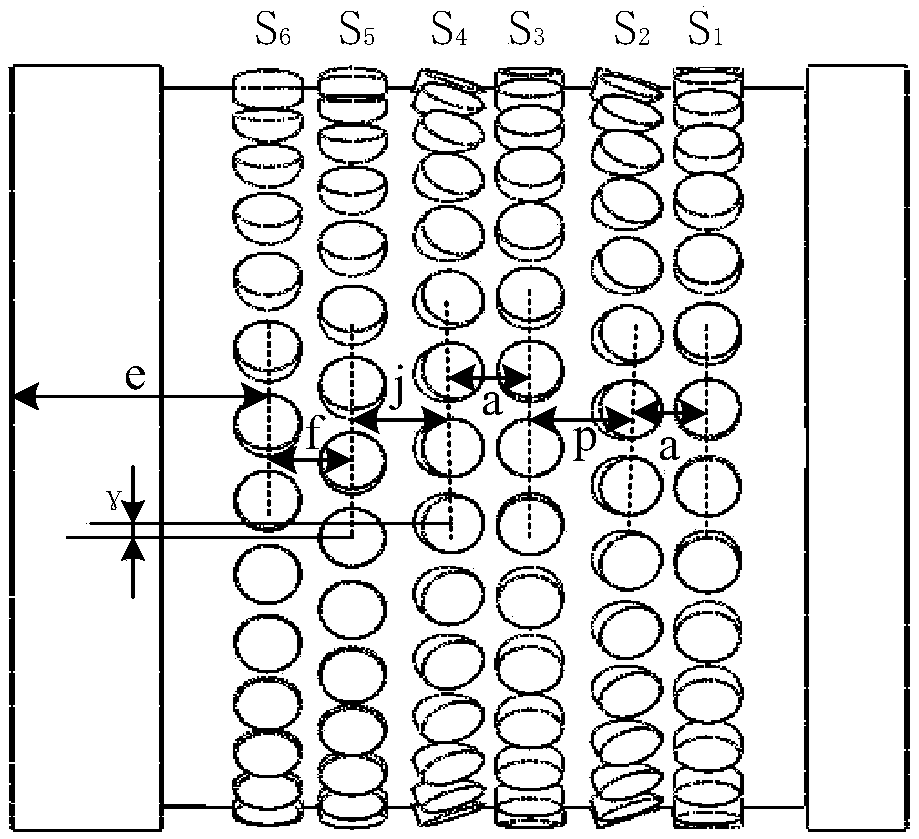

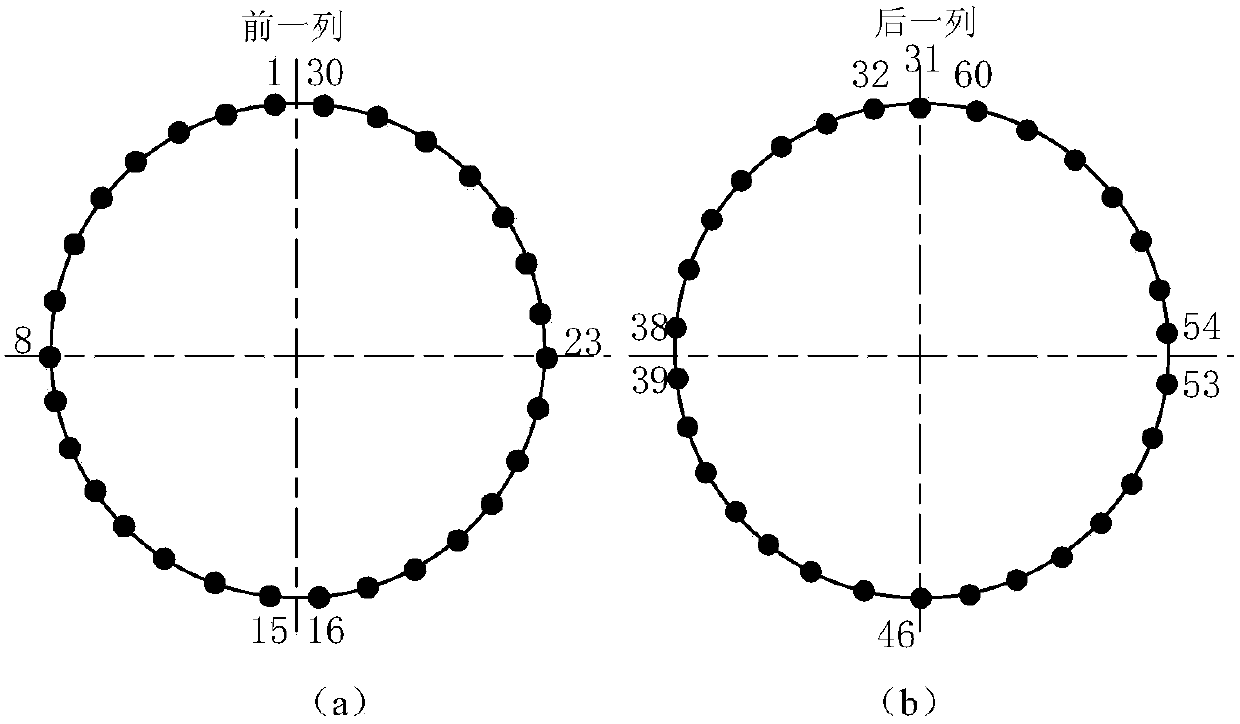

[0049] Step 1.2, the composite sensor array includes two straight probe arrays S uniformly distributed along the inner surface of the pipe 1 And S 3 , Two rows of axially inclined probe array S 2 And S 4 , And two rows of circumferential oblique probe array S 5 And S 6 . Sensor with S 1 →S 2 →S 3 →S 4 →S 5 →S 6 Distribution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com