Method for conversion, export, sharing and query of online flaw detection data

A data and flaw detector technology, applied in the field of data management, to achieve the effect of improving storage efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

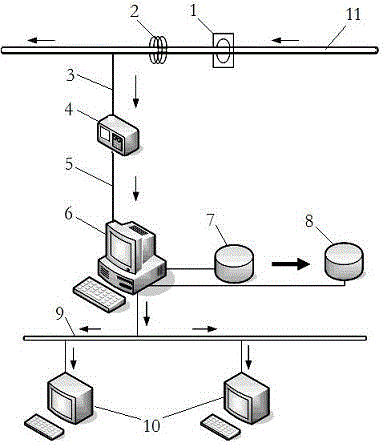

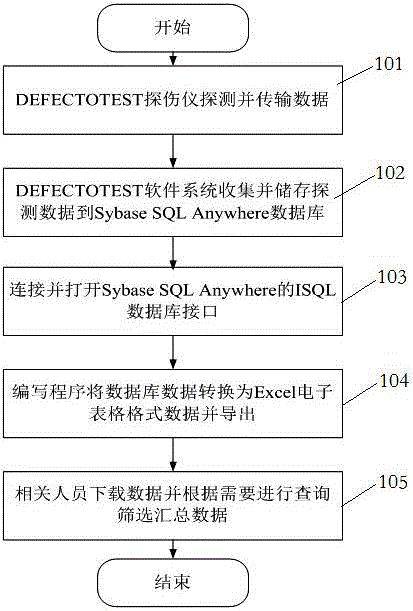

[0012] Embodiment: The model of online flaw detector 6 in the present invention is DEFECTOTEST DS2000; the model of penetration detection system 1 is DEFECTOMAT; the model of rotation detection system 2 is CIRCOGRAPH; the model of detection circuit system 4 is TestElectronics; online flaw detector 6 adopts DEFECTOTEST software system; database 7 using Sybase SQL Anywhere database.

[0013] DEFECTOTEST DS2000 online flaw detector, said DEFECTOTEST DS2000 online flaw detector is equipped with DEFECTOMAT penetration detection system, CIRCOGRAPH rotation detection system, Test Electronics detection circuit system, DEFECTOTEST software system and other core components. After the products produced pass through the DEFECTOMAT penetration detection system and the CIRCOGRAPH rotation detection system, the flaw detection system generates a detection analog signal 3, which is transmitted to the detection circuit system 4 through the cable and converted into a digital signal 5 by the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com