An experimental setup for continuous evaluation of high temperature and high pressure fluid viscosity and shear stability

A technology of high temperature and high pressure, experimental equipment, applied in the direction of measuring equipment, flow characteristics, indirect flow characteristics measurement, etc., can solve the problems of high performance requirements for heat preservation and pressure, lack of longitudinal comparability of results, long time-consuming process of sample transfer, etc., to achieve cost Low, good application effect, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

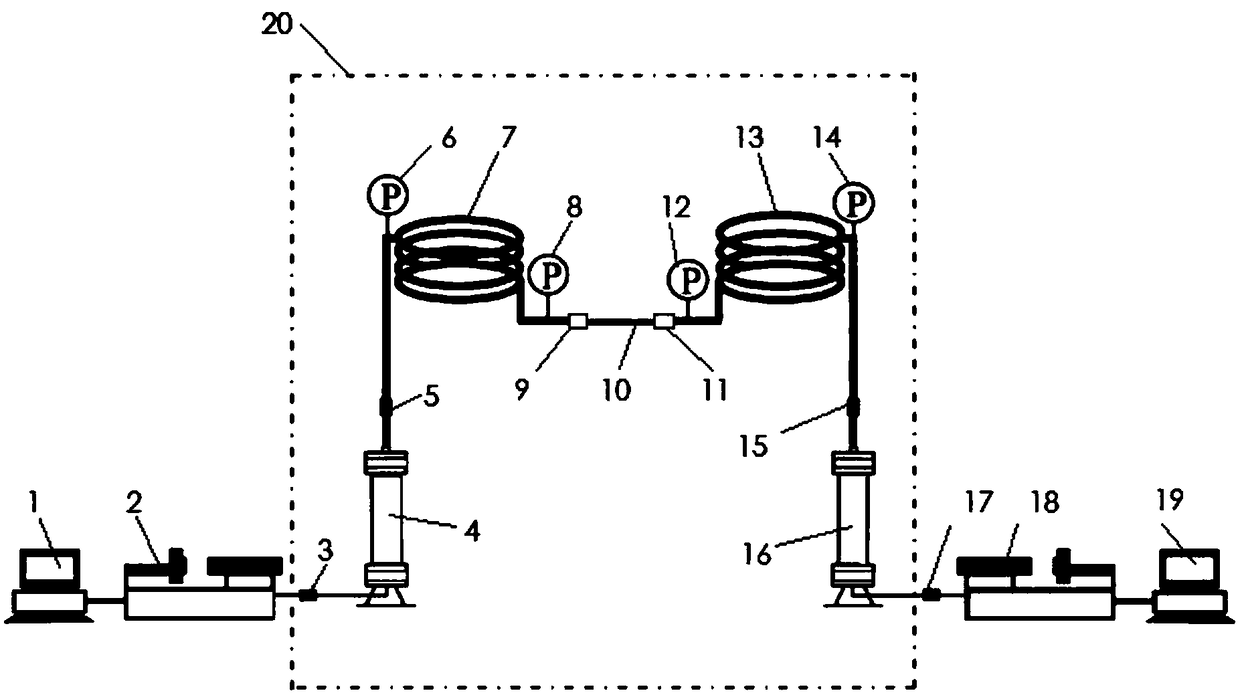

[0028] Put all devices in accordance with figure 1 connected in order. Set the temperature of the constant temperature oven 20 to the target temperature of the experiment, and let it stand for 6 hours to ensure that the temperature of the system reaches the target temperature and is maintained. Then transfer the sample to the intermediate container-4, open the solenoid valve-3, and keep the pressure at the target pressure through the constant-speed constant-pressure pump-2. Open the solenoid valve 2 5, solenoid valve 3 15 and solenoid valve 4 17, inject the sample in the intermediate container 1 4 into the spiral tube 1 7 at a constant speed, read after the pressure on the pressure gauge 1 6 and pressure gauge 2 8 is stable The pressure difference was taken, and the initial viscosity of the sample was calculated using the model in Equation 1 published in the background art. After the sample passes through the capillary 10, a shearing effect occurs, and then enters the interm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com