Combined thermal shock testing system and method in lasting gradient temperature field

A gradient temperature and experimental system technology, applied in the field of heat treatment, can solve problems such as the inability to form a gradient temperature field, the inability to meet the thermal shock experiment requirements of a persistent gradient temperature field, and the difficulty in simulating the service environment of hot-end components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

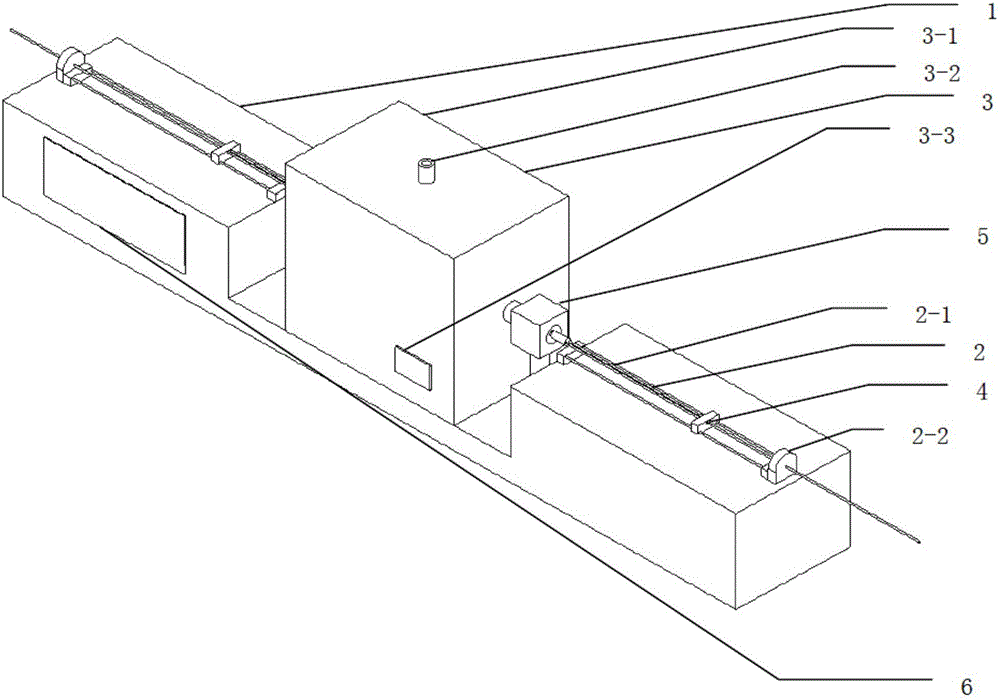

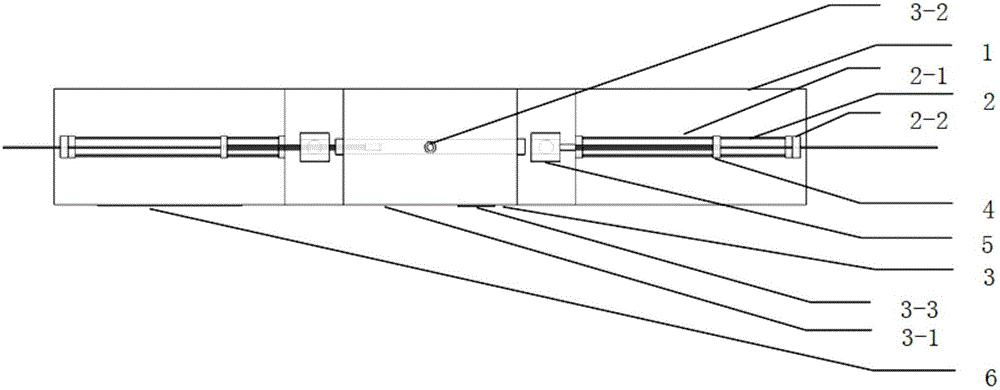

[0031] Such as Figure 1~4 As shown, a combined thermal shock experiment system under a persistent gradient temperature field of the present invention includes a frame 1, a displacement module 2, a heating module 3, an internal cooling module 4, an external cooling module 5, and a measurement and control module 6; wherein, the machine Frame 1 is covered with aluminum alloy plate including but not limited to aluminum alloy truss structure to provide support for the experimental system; displacement module 2 is fixed on the frame 1, including guide rail 2-1 to limit the directional displacement of the specimen, and including but not limited to step The actuating mechanism 2-2 of the feeding motor accurately controls the displacement of the specimen; the heating module 3 is fixed on the frame 1 by including but not limited to a high-temperature tube furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com