A soil direct shear test device and method for simulating immersion-air-drying cycle

A test device and cyclic action technology, which is applied in the direction of using a stable shear force to test the strength of materials, soil material testing, measuring devices, etc., can solve the problems of low test accuracy, cumbersome process, long time consumption, etc., to speed up the test process. , the effect of avoiding cumbersome and control errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

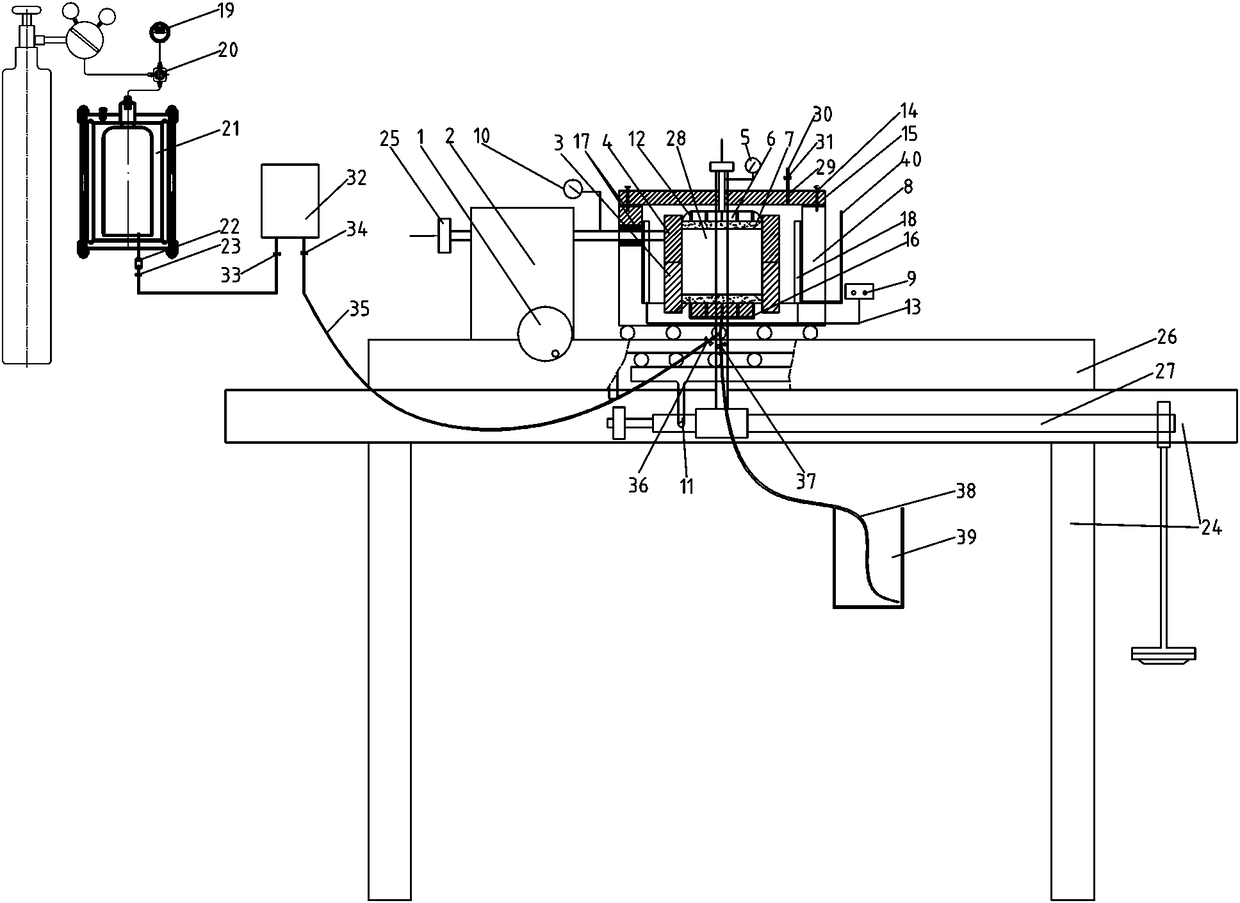

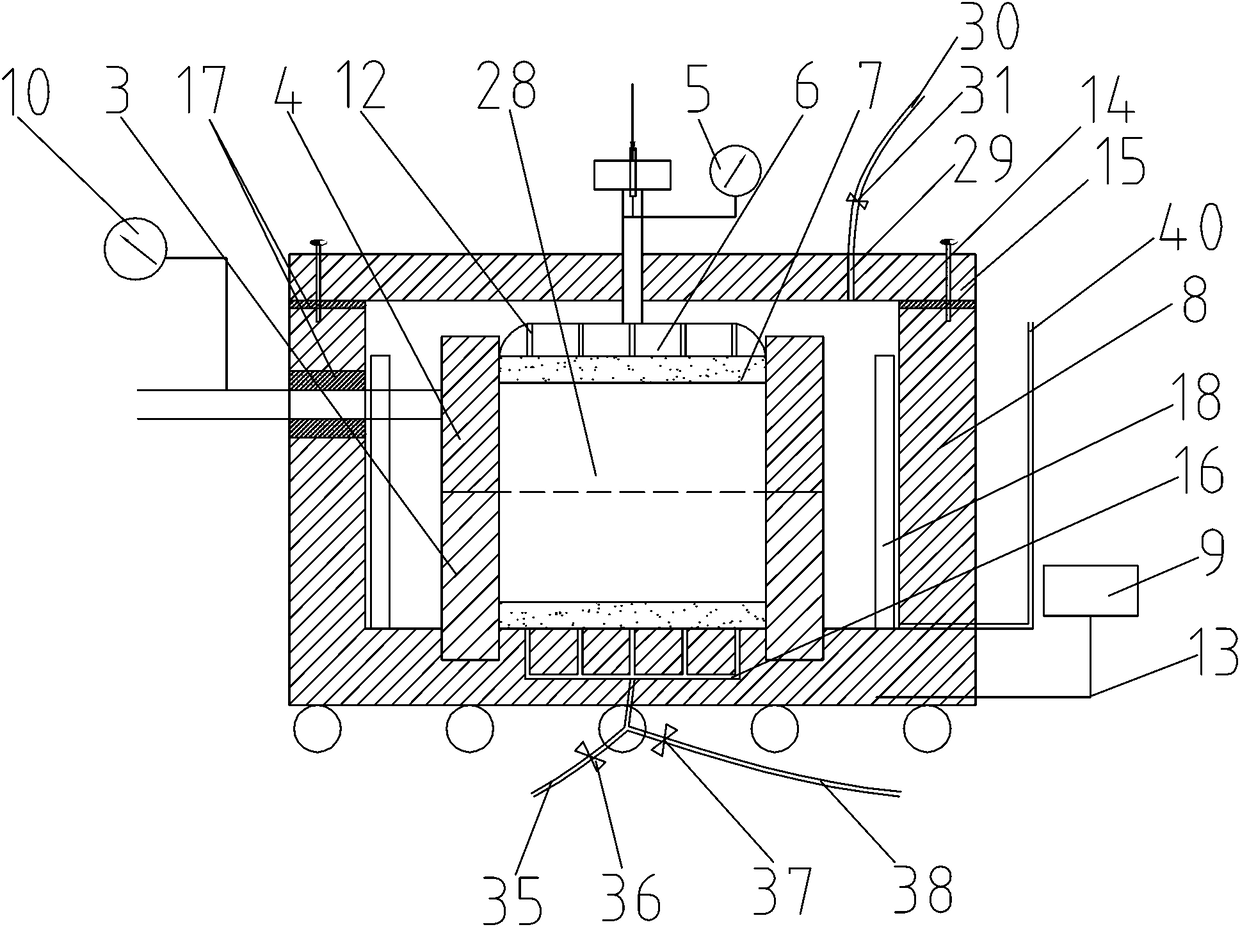

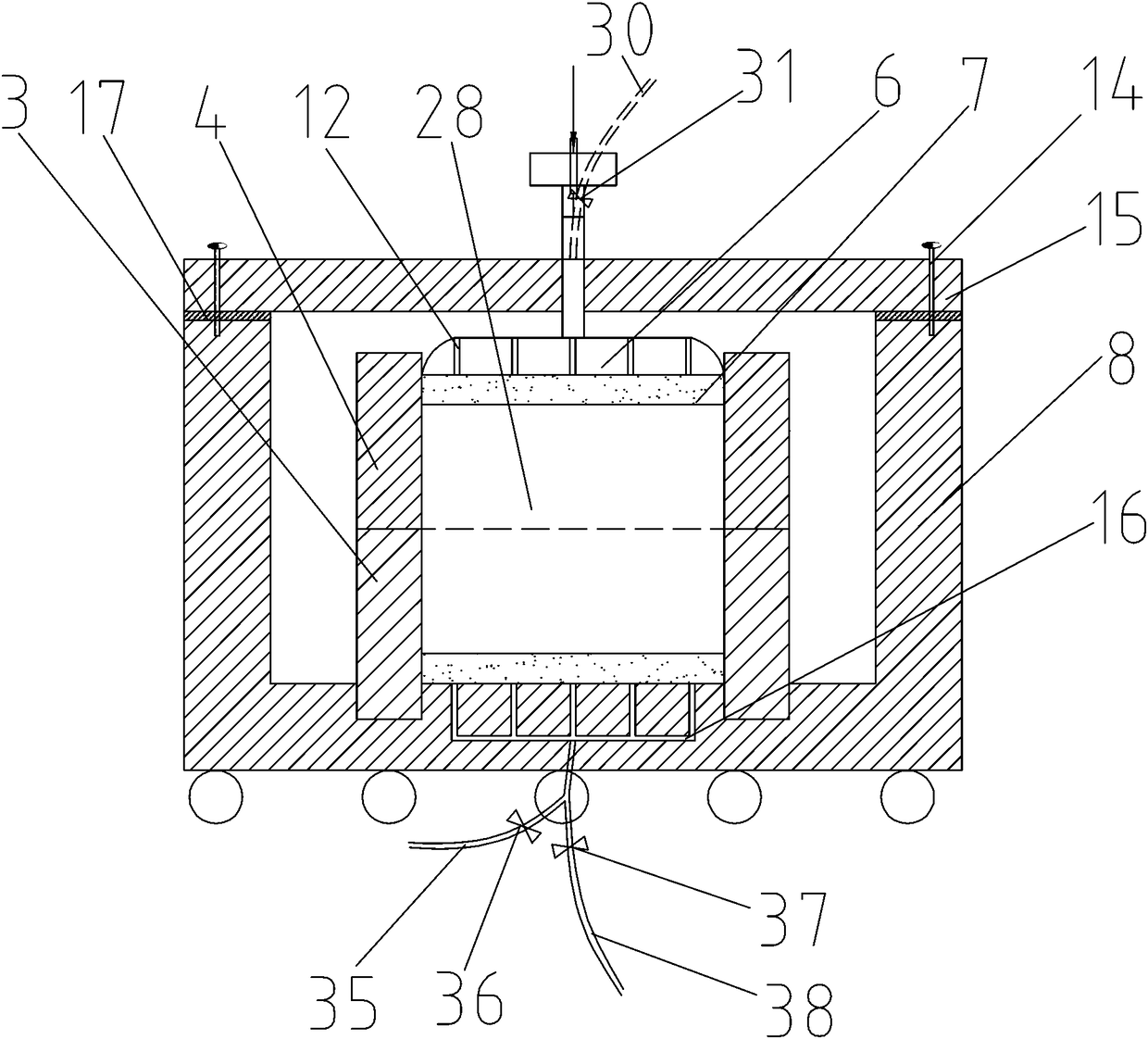

[0038] see Figure 1-9 , a soil direct shear test device simulating soaking-air-drying cycle, it comprises test bench 26, air-water exchanger 21 and support 24, and air-water exchanger 21 communicates with the water storage tank 8 of test bench 26, and support 24 is installed on the bottom of the test bench 26, the test bench 26 is provided with a shearing device, the shearing device includes a normal displacement sensor 5, and the normal displacement sensor 5 is fixed on the pressure transmission rod of the vertical loading device 27 Above, the sealing cover 15 of the porous pressure transmission plate 6 is sealed and connected to the water storage tank 8 through the sealing rubber ring 17 and the fixing bolt 14, and the water inlet channel 16 is set at the bottom of the water storage tank 8, and the water inlet channel 16 will drain the water in the water storage tank 8 The water is transported to the soil sample 28 through the permeable stone 7, and then the soil sample 28 ...

Embodiment 2

[0050] Adopt above-mentioned test device to carry out immersion-air-dry cycle test method, it is characterized in that, it comprises the following steps,

[0051] Step 1: The experimenter first aligns the upper shear box 4 and the lower shear box 3, inserts the bolts to fix them, then puts the permeable stone 7 and filter paper into the lower shear box 3 in sequence, and then places the prepared soil sample 28 Put it into the shear box, and finally place filter paper and permeable stone 7 on the soil sample, cover the porous pressure transmission plate 6, and install the normal displacement sensor 5;

[0052] Step 2: First, place a sealing rubber ring 17 between the water storage tank 8 and the sealing cover 15 on the periphery of the porous pressure transmission plate 6, and then connect the two with fixing bolts 14 to ensure that the water storage tank 8 and the periphery of the porous pressure transmission plate 6 are The inner space formed by the sealing cover 15 has good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com