System for measuring time-resolved flow processes of fluids

A time-resolved, fluid-based technology that is applied in measuring flow/mass flow, detecting fluid flow by measuring differential pressure, and measuring capacity. It can solve problems such as viscosity or density fluctuations, and achieve the effect of eliminating influence and avoiding erroneous measurements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

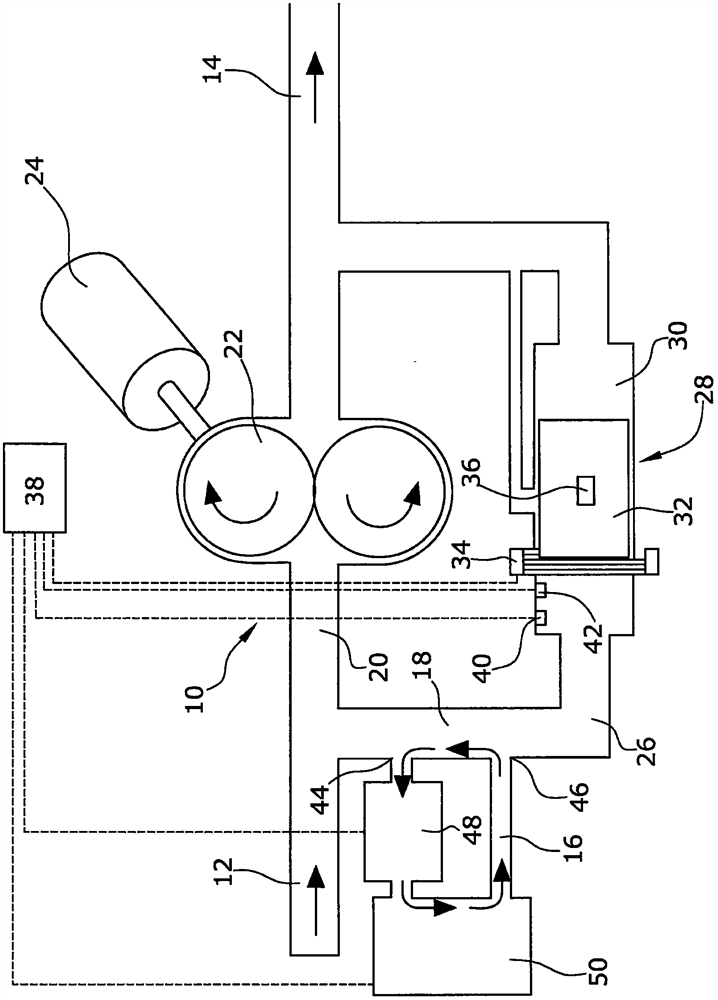

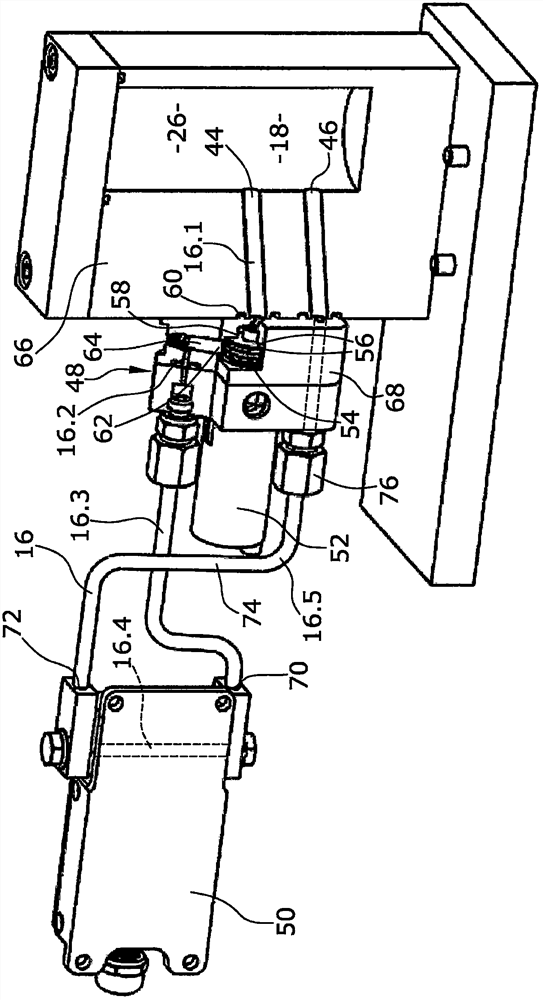

[0026] exist figure 1 The system according to the invention for measuring the time-resolved flow process of a fluid shown in , consists of a flow meter 10 with an inlet 12 and an outlet 14 and a bypass line 16 through which the flow meter 10 can be bypassed. Pipe section 18 .

[0027] Via inlet 12 , the fluid to be measured, in particular fuel, flows from a flow-generating device, in particular a high-pressure fuel pump and at least one injection valve, into main line 20 of flow meter 10 . A rotary extruder 22 in the form of a double gear pump is arranged in this main conduit 20 . Downstream from the extruder 22 , the main conduit 20 ends at the outlet 14 . The gear pump 22 is driven by a drive motor 24 through a clutch or a transmission.

[0028]From the main pipe 20, a detour pipe 26 is branched between the inlet 12 and the rotating extruder 22, and the detour pipe follows the downstream flow of the rotating extruder 22 and then merges into the main pipe 20 between the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com