Combined sealing sleeve for butt-jointing two pipelines and manufacturing method of sealing sleeve

A sealed sleeve, combined technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of inability to meet the requirements of pipe fittings, high cost, low efficiency, etc., to achieve structural Simple, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Such as Figure 5 As shown, the present invention provides a combined sealing sleeve A for connecting two pipes, which is used to connect two left and right pipes B and C of the same specification (such as glass fiber reinforced plastic pipes, steel pipes, etc., with smooth outer surfaces) together, and seal the junction of the two pipes after butt joint, so that the liquid in the pipes will not leak out.

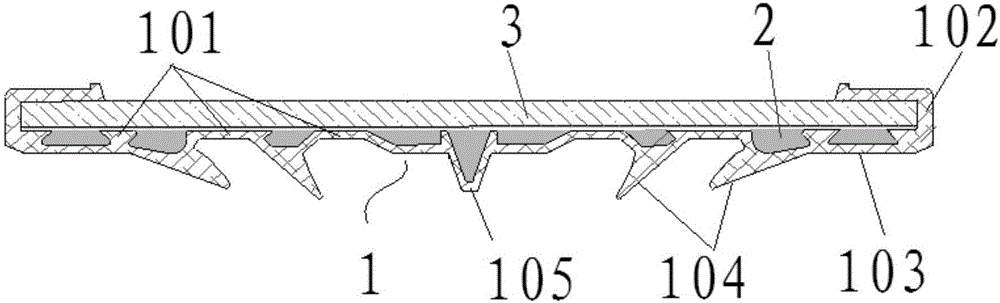

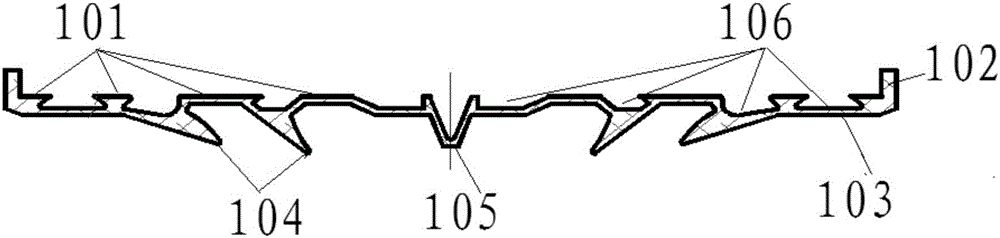

[0031] Specifically, as shown in 1, the combined sealing sleeve A of the present invention includes: a sleeve 3 for butt jointing of two pipelines (i.e. the first pipeline B, the second pipeline C), The sleeve 3 and the sealing ring 1 can be quickly assembled to form the combined sealing sleeve A of the present invention based on the sealing ring 1 of the two pipes that the sealing sleeve is connected to.

[0032] The casing 3 of the present invention is a long casing made of plastic or composite materials or metal materials, and a sealing ring 1 is sleeved in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com