A liftable guardrail device for municipal bridges

A guardrail device, bridge technology, applied in the direction of bridges, bridge parts, bridge construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

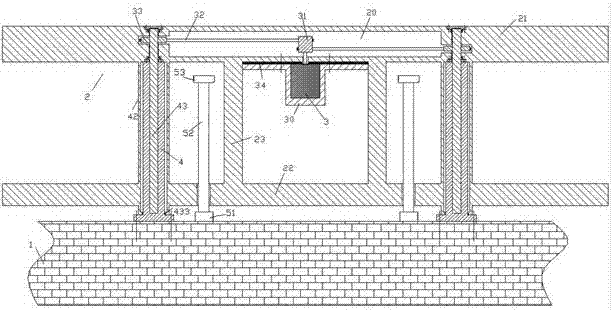

[0009] Combine below Figure 1-3 The present invention will be described in detail.

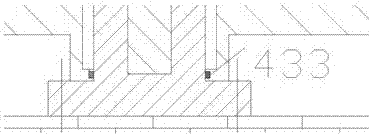

[0010] The liftable guardrail device for municipal bridges according to an embodiment of the present invention includes: a bridge base 1 and a plurality of guardrail units 2 installed on the bridge base 1, and each guardrail unit 2 includes left and right symmetrically fixed on the The two fixed sleeve columns 4 on the bridge base 1, the upper beam 21 and the lower beam 22 that span and extend beyond the two fixed sleeve columns 4, and the upper beam 21 and the lower beam 22 are all set There are circuit devices and are fixedly connected by vertical railings 23; wherein, each of the two fixed sleeve columns 4 is provided with a screw hole threaded with the vertical stud 43, and the vertical stud 43 The upper end extends into the upper beam 21 and is axially fixedly connected with the upper beam 21 through an upper thrust bearing 431 and a lower thrust bearing 432, and the vertical stud 43 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com